Part Analysis

| General Data | |

| Manufacturer (OEM) | RSY |

| PCB Type | Double-Sided |

| Primary Side | |

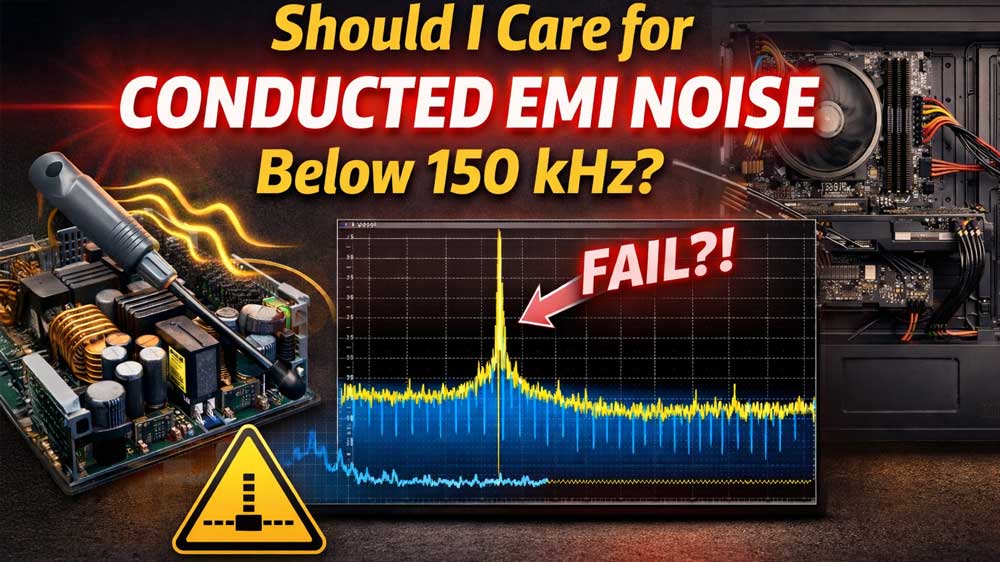

| Transient Filter | 2x Y caps, 1x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | 1x NTC Thermistor & Relay |

| Bridge Rectifier(s) |

1x

|

| APFC MOSFETs |

2x WayOn WML28N60C4 (650V, 23A @ 25°C, Rds(on): 0.16Ohm)

|

| APFC Boost Diode |

1x Maplesemi MSP08065G1 (650V, 27A @ 25°C)

|

| Bulk Cap(s) |

2x Rubycon (420V, 270uF each or 540 both, 3000h @ 105°C, MXK)

|

| Main Switchers |

4x Convert CS13N50FF (500V, 13A , Rds(on): 0.46Ohm)

|

| APFC Controller | |

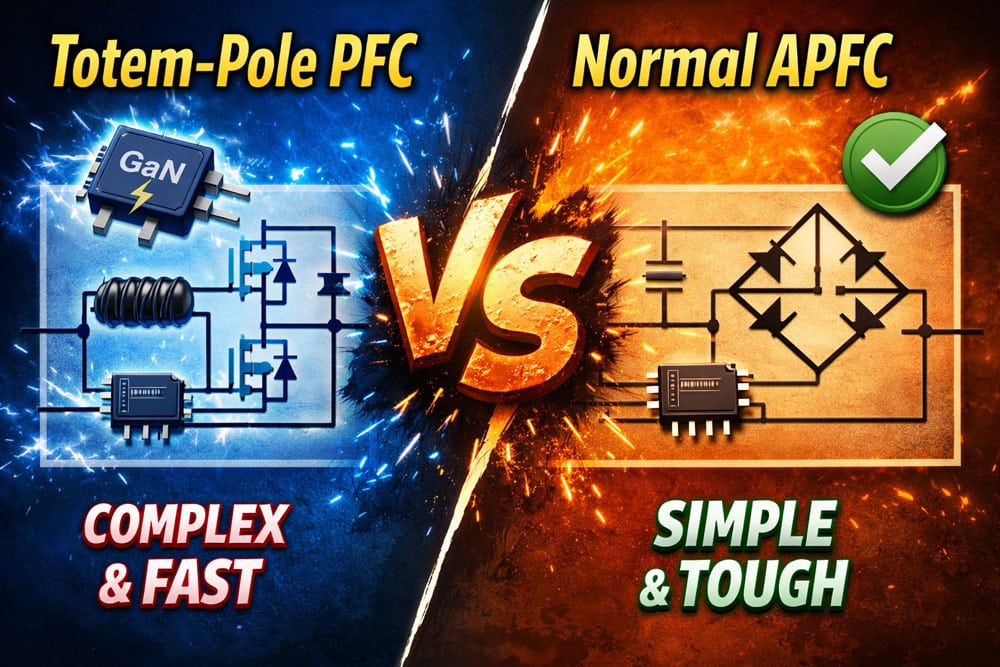

| Topology |

Primary side: APFC, Full-Bridge & LLC converter

Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 4x HUAYI Microelectronics HYG020N04 (40V, 220A @ 25°C, Rds(on): 2.3mOhm) |

| 5V & 3.3V | DC-DC Converters: 4x FETs PWM Controller(s): 2x ANPEC APW7164 |

| Filtering Capacitors | Electrolytic: 1x Rubycon (4-10,000 @ 105°C, YXJ), 3x Rubycon (3-6,000 @ 105°C, YXS), 1x Rubycon (6-10000 @ 105°C, ZLH), Polymer: 4x CAPS, 11x United Chemi-Con, 26x Unicon |

| Supervisor IC | 1S313I-SAG |

| Fan Model | ZIC ZFB122512M (120mm, 12V, 0.25A, Double Ball Bearing Fan) |

| 5VSB Circuit | |

| High Side Rectifier |

1x Shenzhen Foster Semiconductor FIR4N70BLG (700V, 2.5A @ 100°C, Rds(on):3mOhm)

|

| Standby PWM Controller | INFSitronix IN2P070C |

As expected, the tiny PCB is overloaded with parts, allowing it to deliver the PSU’s maximum power. The design is clean, without any power or signal cables altering airflow. RSY extensively used daughter boards to exploit the platform’s height, and the heatsinks are relatively small, but the 120mm fan assists them. The platform uses high-end capacitors and controllers, but the FETs on the primary and secondary sides are by lesser-known manufacturers. This doesn’t necessarily mean that they are of mediocre quality, though.

On the primary side, a PFC converter is used for higher efficiency, and a full bridge topology comes next, along with an LLC resonant converter. On the secondary side, four FETs regulate the 12V rail, which feeds a couple of DC-DC converters to generate the minor rails. All electrolytic filtering caps on the secondary side are by Rubycon. Chemi-Con, Unicon, and another one less known brand make the polymer caps, which are way more tolerant to heat than electrolytic ones but have restricted capacity, which is crucial, especially in ATX v3.x PSUs that have to deliver 200% of their max power for short periods.

The cooling fan is by Zeta Group, and its model number is ZFB122512M. It uses a double ball bearing, which is more tolerant to high operating temperatures and more noise at lower speeds than fluid dynamic bearing fans. Since the PCB is small, its thermal loads will be increased because the parts are close to each other, so a DBB fan is preferred, in my opinion. Moreover, FDB fans are not suitable for frequent start and stop usage scenarios, which are typical in semi-passive PSUs, because this type of fan gets high stress during the start-up phase till the lubricant goes all the way up to the fan’s shaft.

Lastly, the black glue on some parts, including Y caps and coils, restricts vibrations, which are the main cause of coil whine. Yes, despite its name, caps can also produce coil whine noise!

My 9060XT 16GB graphics card has a typical board power (TBP) of 160W to 182W, which requires 13.3A to 15.2A of current. The card uses a 6+2 pin PCIe connector (600mm), but many power supplies use a mix of 16AWG and 18AWG wires for these connectors. Will the 18AWG wires be able to safely handle that much current?

3x gauges handle this current so it is ok.

please mate would you do a review Zalman Teramax II ATX 3.0 ?

will try to do so ok!

–“…and it managed to pass all tests”

Well, I see one red flag on the minor rail. If I’m counting it right, it’s just 0.42% out of 5% tolerance (5.42% under 3.3V)… or I miss something?