Part Analysis

| General Data | |

| Manufacturer (OEM) | High Power |

| PCB Type | Double-Sided |

| Primary Side | |

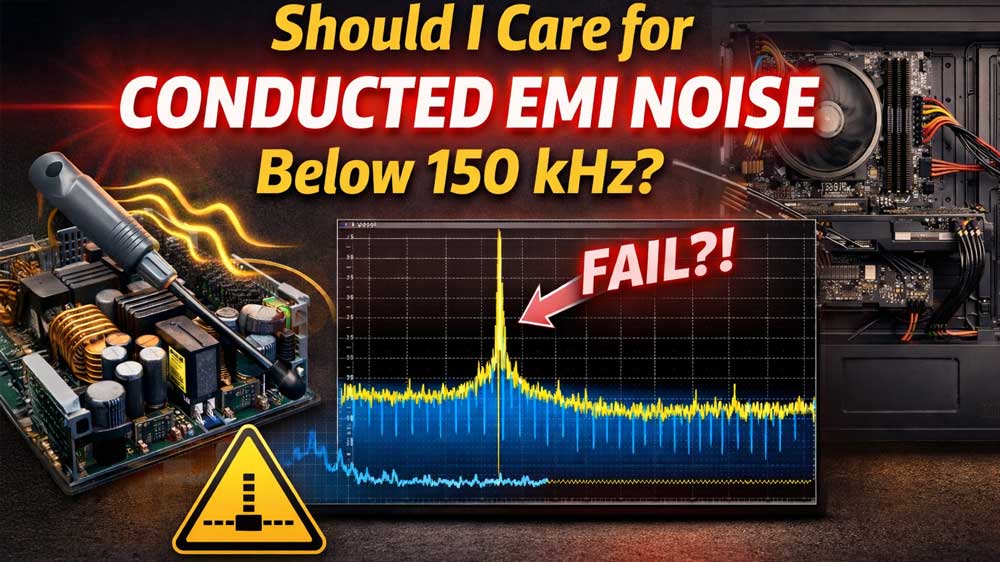

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV, 1x MPS HF81 (Discharge IC) |

| Inrush Protection | NTC Thermistor & Relay |

| Bridge Rectifier(s) |

2x HY GBU1006F (600V, 10A @ 100°C)

|

| APFC MOSFETs |

2x SI28S60F

|

| APFC Boost Diode |

1x Maplesemi MSP08065G1 (650V, 8A @ 150°C)

|

| Bulk Cap(s) |

1x Rubycon (420V, 680uF, 3,000h @ 105°C, MXK)

|

| Main Switchers |

2x SI28S60F

|

| APFC Controller |

Infineon ICE3PCS01G

|

| Resonant Controller | Champion CU6901VAC |

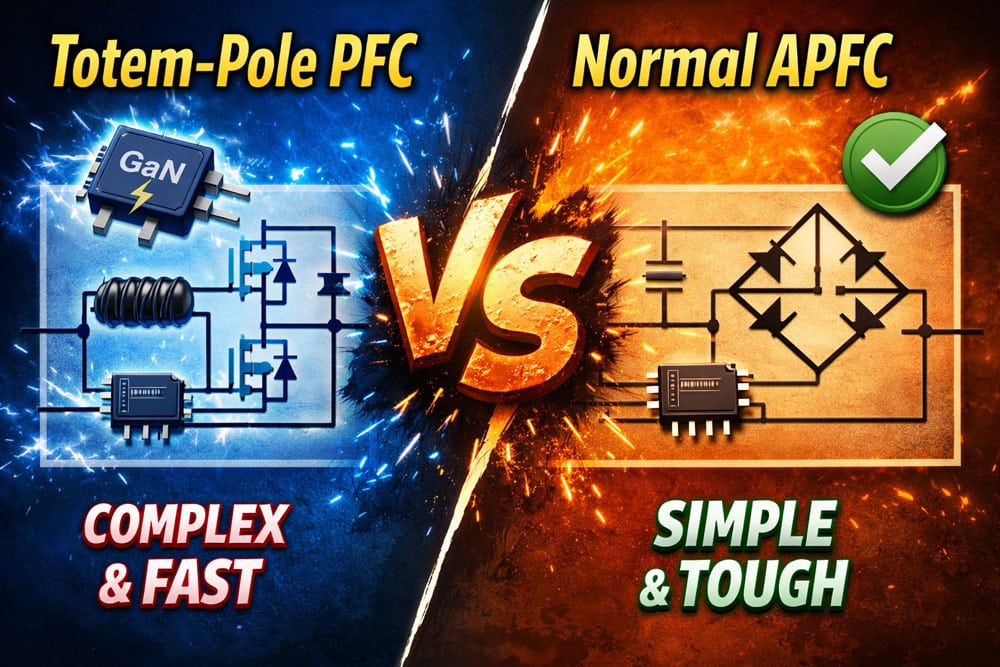

| Topology |

Primary side: APFC, Half-Bridge & LLC converter

Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 6x IPS 014N04SA |

| 5V & 3.3V | DC-DC Converters: 4x Infineon BSC0906NS (30V, 40A @ 100°C, Rds(on): 4.5mOhm) PWM Controller(s): uPI uP3861P |

| Filtering Capacitors | Electrolytic: 1x Nichicon (4-10,000h @ 105°C, HE), 6x Rubycon (3-6,000h @ 105°C, YXG), 4x Rubycon (6-10,000h @ 105°C, ZLH) Polymer: 22x FPCAP, 2x Nippon Chemi-Con |

| Supervisor IC | WT7527RA (OCP, OVP, UVP, SCP, PG) |

| Fan Model | Thermaltake TT-1425 A1425S12S-2 (Hong Sheng) (140mm, 12V, 0.70A, Hydraulic Bearing Fan) |

| 5VSB Circuit | |

| Rectifier |

1x D.G.M.E DG4N70S FET (700V, 2.5A @ 100°C, Rds(on): 3.2Ohm)

|

| Standby PWM Controller | SI8016HSP8 |

| -12V | |

| Rectifier |

1x KEC KIA7912PI (-12V, 1A)

|

High Power provides the platform and uses a design for the modular board, which I rarely encounter in high-end or mid-end units. The modular board is connected to the primary one through cables instead of bus bars. This means that increased energy will go wasted on the connecting cables, especially at high loads, and airflow is affected as well. The PCB’s design doesn’t leave room for the modular board to be directly connected to it, but with some rearrangement, this could be the case. After all, the PCB is not densely populated; however, lots of space is available in the transient filter area.

On the primary side, besides the APFC converter, we find a half-bridge topology and an LLC resonant converter for minimized energy losses. A synchronous rectification scheme for the 12V rails and a pair of DC-DC converters generate the minor rails on the secondary side. The build quality is good, and the electrolytic caps that High Power used after TT’s request are highly reliable especially the bulk caps.