Real Capacitor Testing: easier said than done! In today’s electronics you will find capacitors everywhere, playing an important role in every products lifetime. This is why it is of imperative importance to be able to just their quality and tolerance to abuse, using scientific methods that don’t require prolonged testing periods.

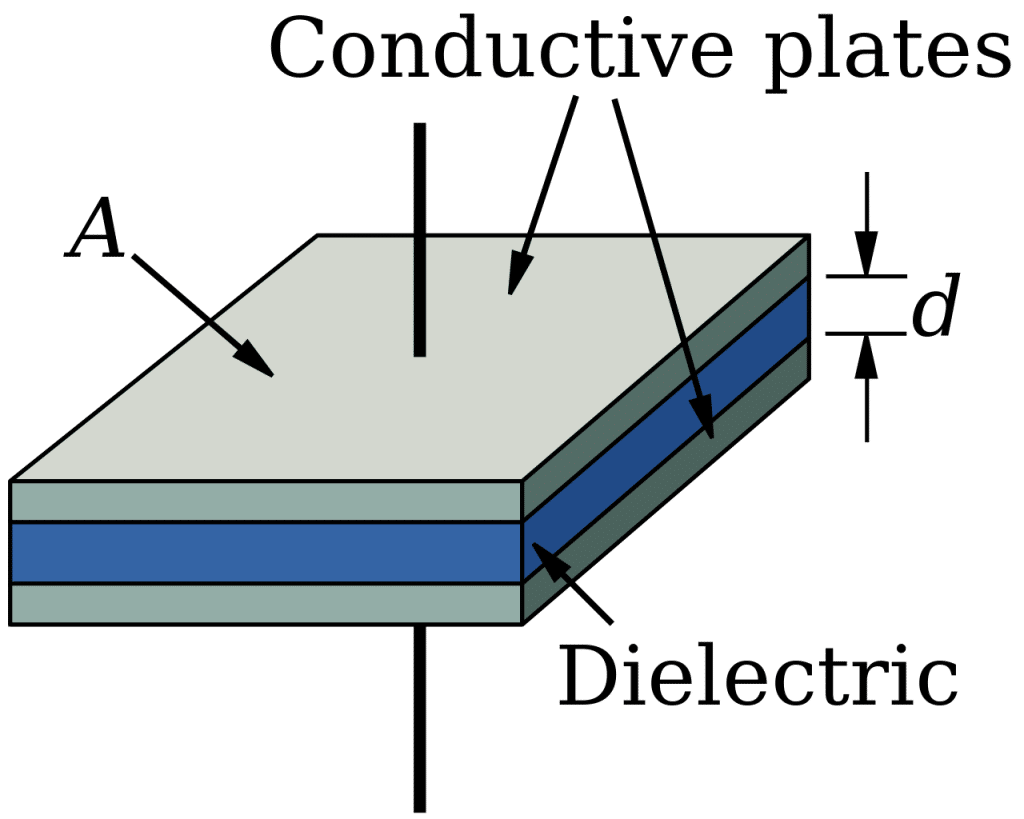

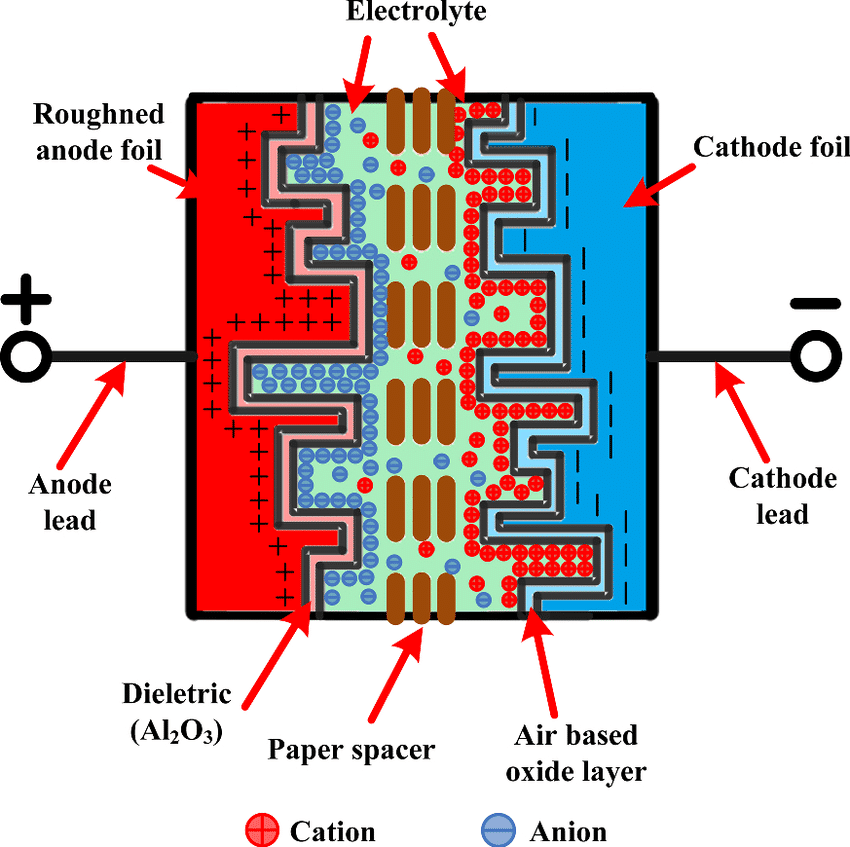

A capacitor is an electronic component that stores and releases electrical energy in a circuit. It consists of two conductive plates separated by an insulating material known as a dielectric. An electric field is created when voltage is applied across the plates, causing the capacitor to store energy. Capacitors are commonly used in electronic circuits for various purposes, such as smoothing power supply voltages, filtering signals, and timing applications. They are characterized by their capacitance, measured in farads (F).

Quality capacitors are essential to any electronics component, including, of course, power supplies, which are used by any electronics device nowadays, not only your PCs. Usually, high-end PSUs, like the Corsair RM1000x (2021), use Chemi-Con capacitors, while mid-level PSUs use more affordable caps from either Teapo or Elite.

Overvolting a capacitor or applying a voltage beyond its rated voltage can lead to several undesirable consequences:

- Breakdown and Damage: Exceeding the voltage rating can cause the dielectric material between the capacitor plates to break down. This breakdown can result in a short circuit, damaging the capacitor and potentially other components in the circuit.

- Reduced Capacitance: Overvoltage can alter the physical and electrical properties of the capacitor, leading to a decrease in capacitance. This change can affect the performance of the capacitor in the circuit.

- Leakage Current: Overvoltage stress can increase the leakage current across the capacitor. Leakage current flows through the dielectric material, and excessive leakage can negatively impact the performance of the capacitor.

- Electrical Failure: Prolonged exposure to overvoltage conditions may lead to the gradual degradation of the capacitor, eventually resulting in electrical failure.

- Safety Hazards: In extreme cases, overvoltage can cause the capacitor to fail catastrophically, leading to the release of smoke, gas, or even rupture. This poses safety risks, especially in applications where the capacitor is close to other components or in an enclosed space.

So far, we know from experience that Japanese capacitors are better than Taiwanese ones, and Taiwanese caps are better than Chinese caps. However, relying solely on the provided specifications, experience, and rumors is not the most scientific way to judge a product. During a visit to Great Wall’s HQs, I noticed that its R&D center conducts exhausting capacitor testing, pushing the test subjects to their maximum ratings to determine whether the official specs are correct.

I cannot have capacitors tested at 105C for 2,000 or 3,000 hours because I lack the equipment, the time, and the money to pay for the electricity bills. So, I decided to replicate another test that GW also conducts. They overvolt the capacitors under test till they explode, determining their tolerance to higher than the nominal voltage levels; judging this way, the dielectric’s quality. The higher quality caps will be more tolerant to overvoltage.

Since I wanted to see how this new experiment would go down, I decided to start slowly, using equipment I already had in the lab, and not invest from the start in extra equipment. This means that for the moment, I will only test lower voltage capacitors and not bulk caps with voltage ratings of 400V and above.

I know that the Chemicon W series is a custom specification. I would like to see a comparison between similar specifications like TEAPO SC and Chemicon KZE.