Part Analysis

| General Data | |

| Manufacturer (OEM) | HKC |

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 6x Y caps, 2x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | 1x NTC Thermistor 2.5D-15 (2.5 Ohm @ 25°C) & Relay |

| Bridge Rectifier(s) |

2x Diodes GBU1506 (800V, 15A @ 125°C)

|

| APFC MOSFETs |

2x LONTEN LSD65R180GT (650V, 20A @ 25°C, Rds(on): 0.018Ohm )

|

| APFC Boost Diode | 1x Global Power Tech. G3S06004J (600V, 11A @ 25°C) |

| Bulk Cap(s) |

2x Rubycon (420V, 330uF each or 660uF combined, 2-3000h @ 105°C, MXH)

|

| Main Switchers |

2x MPVA20N50F (500V, 20A @ 25°C, Rds(on): 0.26Ohm )

|

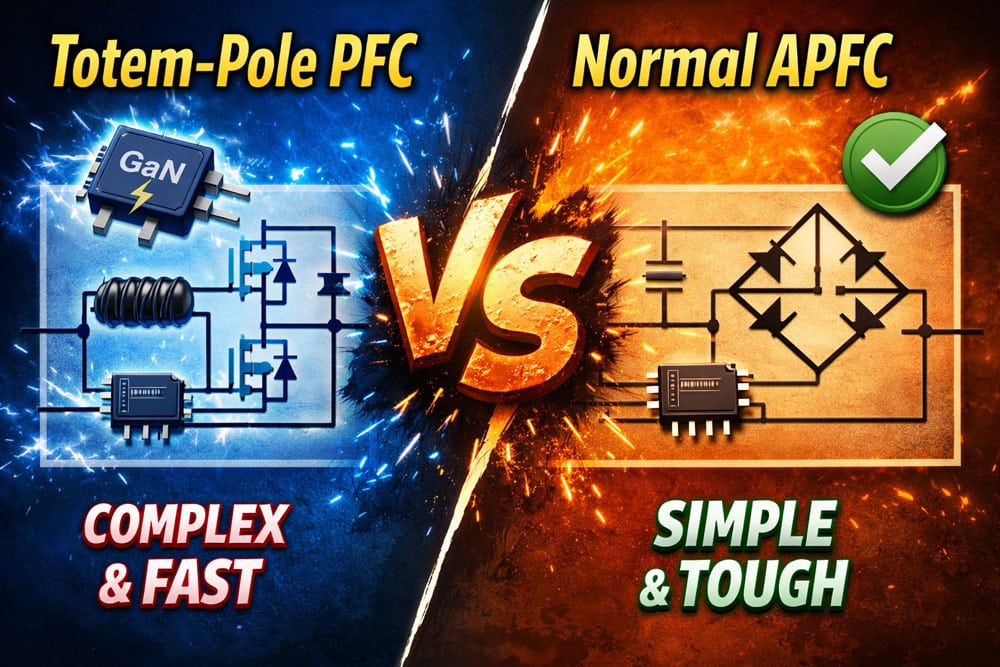

| APFC Controller |

Champion CM6500UNX

|

| Resonant Controller | Champion CM6901X |

| Topology |

Primary side: APFC, Half-Bridge & LLC converter

Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 4x Advanced Power Electronics AP4NA1R4CMT-A (45V, 39A @ 70°C, Rds(on): 1.4 mOhm) |

| 5V & 3.3V | DC-DC Converters: 2x Advanced Power Electronics AP4024GEMT-HF (30V, 20.9A @ 70°C, Rds(on): 4.5mOhm) 2x Wayon WMB040N03LG2 (30V, 38A @ 100°C, Rds(on): 4.0mOhm)PWM Controller(s): 2x ANPEC APW7164 |

| Filtering Capacitors | Electrolytic: 6x CapXon (3,000h @ 105°C, KF) 3x Teapo (3,000h @ 105°C, SC)Polymer: 21x CapXon |

| Supervisor IC | IN1S3151 – SAG |

| Fan Model | TT-1225 (AV-F12025HS) (120mm, 12V, 0.3A, Sleeve Bearing Fan) |

| 5VSB Circuit | |

| Rectifier |

SB1045L (45V, 10A)

|

| Standby PWM Controller | PN8141 |

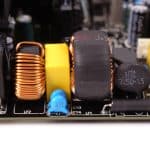

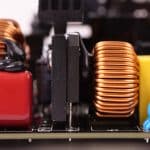

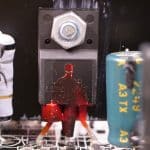

According to the markings on the platform, it can deliver from 500W up to 850W, depending on the used parts. The PCB is small and well under-populated, with the FETs regulating the 12V rail being directly exposed to the fan’s airflow. There is a small heatsink right beside them, adding some extra cooling. Contrary to most PSU designs, the DC-DC converters generating the minor rails are installed on the main PCB, while a series of filtering caps surround them, used by all main rails.

On the modular PCB, two sockets are left empty. The filtering capacitors at this stage are by CapXon, polymer, and electrolytic ones. There are also two Teapo SC ones. Thermaltake instructed HKC not to use Japanese caps on the secondary side to keep costs down. Now that we have started evaluating capacitors, we will soon be able to provide you with an estimated impact on reliability, depending on the used caps.

On the primary side, the PSU uses a half-bridge topology and an LLC resonant converter for lossless switching. The bulk caps are by Japanese manufacturers to increase reliability and provide some marketing bonus since “Japanese” caps always sound good to potential buyers. Lastly, the soldering quality of the PSU is typical HKC, which means good quality.