Part Analysis

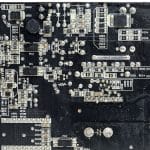

| General Data | |

| Manufacturer (OEM) | HEC |

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 4x Y caps, 3x X caps, 2x CM chokes, 1x MOV, 1x Power Integrations CAP200DG (Discharge IC) |

| Inrush Protection | NTC Thermistor SCK-056 (5 Ohm) & Relay |

| Bridge Rectifier(s) |

2x GBU1506 (800V, 15A @ 100°C)

|

| APFC MOSFETs |

2x Great Power GP47S60 (600V, 47A, Rds(on): 0.081Ohm)

|

| APFC Boost Diode |

1x CREE C6D10065A (650V, 10A @ 155°C)

|

| Bulk Cap(s) |

1x Teapo (400V, 680uF, 2,000h @ 105°C, LS)

|

| Main Switchers |

2x GP36S60YERD

|

| APFC Controller |

Champion CM6500UN & CM03AX

|

| Resonant Controller | Champion CM6901T6X |

| Topology |

Primary side: APFC, Half-Bridge & LLC converter

Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | no info |

| 5V & 3.3V | DC-DC Converters: 4x Potens Semiconductor PDD3906 (30V, 51A @ 100°C, Rds(on): 6mOhm) & 4x Excelliance MOS EMB07N03V (20V, 17A @ 100°C, Rds(on): 7mOhm) PWM Controller(s): 2x APEC APW7073 |

| Filtering Capacitors | Electrolytic: 11x Teapo (1-3,000h @ 105°C, SC), 1x Nichicon (4-10,000h @ 105°C, HE) Polymer: 4x Elite, 6x Teapo, 13x no info |

| Supervisor IC | Weltrend WT7527RT (OCP, OVP, UVP, SCP, PG) |

| Fan Model | Hong Hua HA1225H12F-Z (120mm, 12V, 0.58A, Rifle Bearing Fan) |

| 5VSB Circuit | |

| Rectifier |

1x PS1060L SBR (60V, 10A)

|

| Standby PWM Controller | Power Integrations TNY290PG |

The RMx (Shift) and RMx use platforms by CWT, but for RMe, Corsair decided to trust HEC, which has vast experience in building affordable platforms. The parts used are not by top-notch manufacturers like Infineon, Chemi-Con, Rubycon, etc., but still are by decent brands, which is why Corsair provides a long, seven-year warranty.

On the primary side, we find the typical stuff for a modern PSU: APFC, half-bridge topology, and an LLC resonant converter. On the secondary side, FETs regulate the 12V rail, while the minor rails are generated through a pair of VRMs.

The cooling fan is by Hong Hua and uses a rifle bearing for lower noise output which might not be as good as a similar spec fluid dynamic bearing but still is massively superior to a plain sleeve bearing. Lastly, the soldering quality is not the best I have seen from HEC, but I got an early review sample, so it might be better in the mass-production units.

I almost bought RM850e 2023 but have heard so many complaints of coil whine. I am in India and I cannot return the product once purchased. Can you please tell me if coil whine is an issue? My PC is 5600x + RTX 3080 (with 0 rpm fan) – its a work and game PC. While working, I prefer absolute silence since my RTX 3080 has 0 RPM fan mode, so I don’t want PSU to add noise.

Coil whine has to do mostly with the rest hardware, and not the PSU alone. Unfortunately many PSUs with LLC resonant converters and burst operation, can have coil whine at light loads. This is why some brands deactivate it, in secret, after they get their certifications! Affecting this way efficiency at light loads.

Do all RM850e have that LLC resonant converters and burst operation? And is this only used in budget PSUs?

Yes, nope LLC is found on higher-end PSUs for higher efficiency.

Is there any information on the Corsair RM1200e? i can’t find much about it. I do see where it has a 10 year warranty instead of 7 years though.

I haven’t tested it yet, sorry.

No problem, Thanks for the quick reply, It’s hard to find out anything about it but it currently only costs like $10 more than the RM1000e on Newegg, Do you have plans to test it?

I decided to go with the 1000watt RM1000e. Since that was listed in tier A list, I figured it will run silent more than the 850 in my system. looking forward to trying it out.

Looks like shortage of chips is still bad. My order is set for delivery in March.

Three months for the RM1000e! Wow..

I have a older tx750w and was thinking that this rm850e would be a nice upgrade?

Ryzen 7, RTX4070 with 3 harddrives and 2 nvmes.

Do these still show sign of coil whine?

The shift is not a option.

It will be a good upgrade, yes.

Or do I need one of those which connect to 4 ports of the PSU and not just ?

https://store.cablemod.com/product/cablemod-c-series-pro-modflex-sleeved-12vhpwr-pci-e-cable-for-corsair/

I would get Corsair’s official cables for the RMe.

Hi. I have just installed the 1000w version and have a problem with the 12VHPWR cable on my Asus TUF 4090. The red LED of the card lights up when the PC is off (as intended) but it stays on when I switch on the PC. This means that the card does not receive the proper power and remains off so that the PC does not boot. When I use the 4×8 to 12VHPWR Adapter which is included in the card and connect this adapter to 4 cables of the PSU the red LED of the 4090 turns off as soon as I switch in the PC and the PC boots properly. Does this included 12VHPWR cable deliver 600w or not? Or is it just broken?

as far as I know Corsair ships 600W cables with its PSUs. You could measure the Sense0 and 1 pins of your cable with a multimeter, if you have one, to see if both are grounded. IF they are, then the cable is set for 600W.

Thanks for coming back but I’m gonna send the Corsair PSU back as it did not solve my problem. For 2 weeks my PC keeps randomly shutting off, I mean really turning off with no error message, no freeze, no reset etc., just like I would switch off the PSU. I have removed all my sleeved PSU extensions, I have now even tried the Corsair PSU instead of my current Dark Power 11 1200W, but it makes no difference. Must be a kind of safety protection triggered, but it’s so random, sometimes unter high load in a stress test, sometimes “medium” load in games, sometimes desktop only. I have also noticed some kind of short “stutter” (like a short decrease of the general operation noise) coming 1-2 times a day when I watch or play with my UST projector, could it be that I have kind of low voltage dips in my house and the PC PSU is turning off because of that? Could an UPS then help? But then it must be huge one to run the system stable with a 4090 and a 13700k, like 2000VA? Or is there a cheaper way to “stabilize” the voltages for one power plug at home? Too many questions sorry ;)…..

It doesn’t look to be the PSU then but something else. You should check your home’s electrical infrastructure if everything is ok. These low voltage dips, brownouts, definately affect every electronics device, including PCs of course. A 1500VA UPS could support your system, if it is true sine. If you have electrical issues, a UPS could help, yes.

Hi again,

Since posting my joy about the Corsair RM850e power supply. I had to return it. I brought it from the UK with the UK plug.

My rig is old school. On a Haswell Icore 7, 4960K, Z97 intel platform.I had to upgrade the 500watt power supply for a new GTX 3060 gpu.So chose the Corsair Rm850e PSU.And for future proofing.

To my surprise the RM850e had a coil whine and

a buzzing sound. This sound was reverberating through my 5.1 analogue speaker system. To be sure I removed the gpu to isolate the cause. And the coil whine and buzzing sound was still there.

I also stumbled upon a Corsair forum and they spoke about the RMxxxE. And reported similar tales of woe.

Now I am looking for a new PSU.

Coil whine seems to be a big problem again.

I noticed something strange but since i do not own an oscilloscope anymore maybe you can investigate more.

If and when the time allows i know you busy with the new house.

Since i plugged in the Asus RTX 3070, the coil whine from the card gets back to the 12v and 3.3v lines and the op-amps from my Audigy card deliver it to the headset. The same whine from GPU i can hear in the PSU transformer. There are a lot of users reporting Asus GPU’s for the noise generated by SAP II coils.

I noticed that the 5V line it’s not impacted and tested with an step-up convertor from 5V to 12v and step-down 3.3v and the audio card

on a pci-e extension cable ( just data with separate power). No more coil whine in the headset.

Changed the PSU from an 9 year old Corsair to a Thermaltake GF1 and the noise it’s like 20db less now but still there.

On the Asus card i traced the 12v line from pci-e slot to the memory VRM but cant find usage for the 3.3v, maybe some hidden trace inside PCB.

Most GPUs do coil whine at high FPS, during gaming menus for example.

I know all GPU’s have this more or less. But if I want clean audio looks like 2 PSU’s for me.

P.S. the old RTX2060 didn’t have this issue, headset or external AMP were clean of this noise.

What is the maximum power wattage output before the protection circuit kicks in??

Check in the Protection Features page, for this info, because it relies on the temperature, too.

Hello,

I saw two really comprehensive reviews on this Power supply. I decided to go for it for the UK model.

I have the 850-watt model(2023) as I do not intend to use an RTX 4090 or beyond. An RTX 3060 be my sweet spot in GPU.

I notice that on the back of the RM850e box, it says 105C Japanese caps.

On HBuster the review of the RM1000e artwork box just says – 105C Capacitors. I also checked with the RMx model box and it says 105C Japanese capacitors.

The RMe 2023 models do seem to have Japanese caps then.

That was great news as I was going to go for the RMx for an extra 20 UK pounds.

Because of huge capacity shortage, most of the good brands now use whatever they can find and is equal or better than the original specs.

Taka.

You talking crap.Shut up…..

Hello Aris,

The soldering it’s bad as it can be. Off centered and off axis SMD, cold joints and manual soldering for some parts. High Power parts with half the flux.

You call this “Average soldering quality”? This thing it’s a fire hazard waiting to happen.

BTW can you give an example of bad soldering in your reviews?

Hi there! This unit is a fire-hazard? It passed hours of testing under the toughest possible condition without breaking or creating any issues.

Where did you see cold joints? If a joint is cold, the unit wouldn’t work at the first place.

Believe me this is average to my eyes. For me notably problems are mostly long component leads which can create shorts and when solder is missing, creating poor connections and increased resistance.

This is bad soldering example: https://www.techpowerup.com/review/xigmatek-maverick-s-500/4.html

The manual soldering done on some SMD parts point me to this cold joints issue, if the QC misses one then here you go.

Also too little flux for the FET’s could lead in time to a crack. Those parts get thermal cycle all day long.

Remember the we don’t buy PSU’s for 1-2 years.

Yeah the example is real bad, thanks for sharing.

Keep up the good work man.

I’ve noticed quite a few reviews of this PSU, both online and one person I know personally, which have reported really bad coil whine issues just by turning the PSU on. I’m wondering if there was a large bad batch that went out and the rest are fine or if this is a bigger problem. Regardless, I’m really glad to see a slightly more budget series from corsair to slip between their cxm and rmx series assuming this coil whine issue isn’t widespread.

This is a new product, just got released, so you probably refer to the previous RMe. We didn’t notice any strange issues in our tests, and we have tested almost a dozen different RMe models.

Hello,

Any incoming review of the RM850e model?

Once they send us a sample, sure!

Ah my mistake. Thanks for the clarification. I guess me and a couple others just got unlucky.