In today’s review I will evaluate Cooler Master’s fresh air coolers, the V4 Alpha 3DHP and both versions of the Hyper 212 3DHP, black and ARGB. You will soon find out if CM’s new philoshophy, less is more, actually works in air coolers.

After the Superconductive Composite Heat Pipes (SCHP) found in the Hyper 612 Apex that I have recently evaluated, Cooler Master went to the 3D Heat Pipe technology for the fresh V4 Alpha and Hyper 212 coolers. To easily distinguish, CM added the “3DHP” word at the end of their model numbers.

According to CM, this new design adds a Heat Pipe end in a previously unused space to boost cooling performance and reduce noise by expanding surface contact and accelerating heat dissipation. Both new coolers use just two heatpipes, hence CM’s motto “less is more”, but because of the latest design, these two heatpipes offer higher performance than a standard duo of heatpipes.

The models that I am going to evaluate in this review are the following:

- Hyper 212 3DHP Black

- Hyper 212 3DHP Black ARGB

- V4 Alpha 3DHP Black

All use the same heatsink, but with some differences in the cooling fans. To find out the differences, along with the suggested prices, look at the following table.

| Model Number | Model Name | Fans | Price |

|---|---|---|---|

| MAY-T2HP-217PK-R1 | Hyper 212 3DHP Black | CM Mobius 120 | 29€ / $30 |

| MAY-T2HP-217PA-R1 | Hyper 212 3DHP Black ARGB | CM Mobius 120 ARGB | 29€ / $30 |

| MAZ-T2HP-217PK-R1 | V4 Alpha 3DHP Black |

|

39€ / $40 |

3DHP Explained

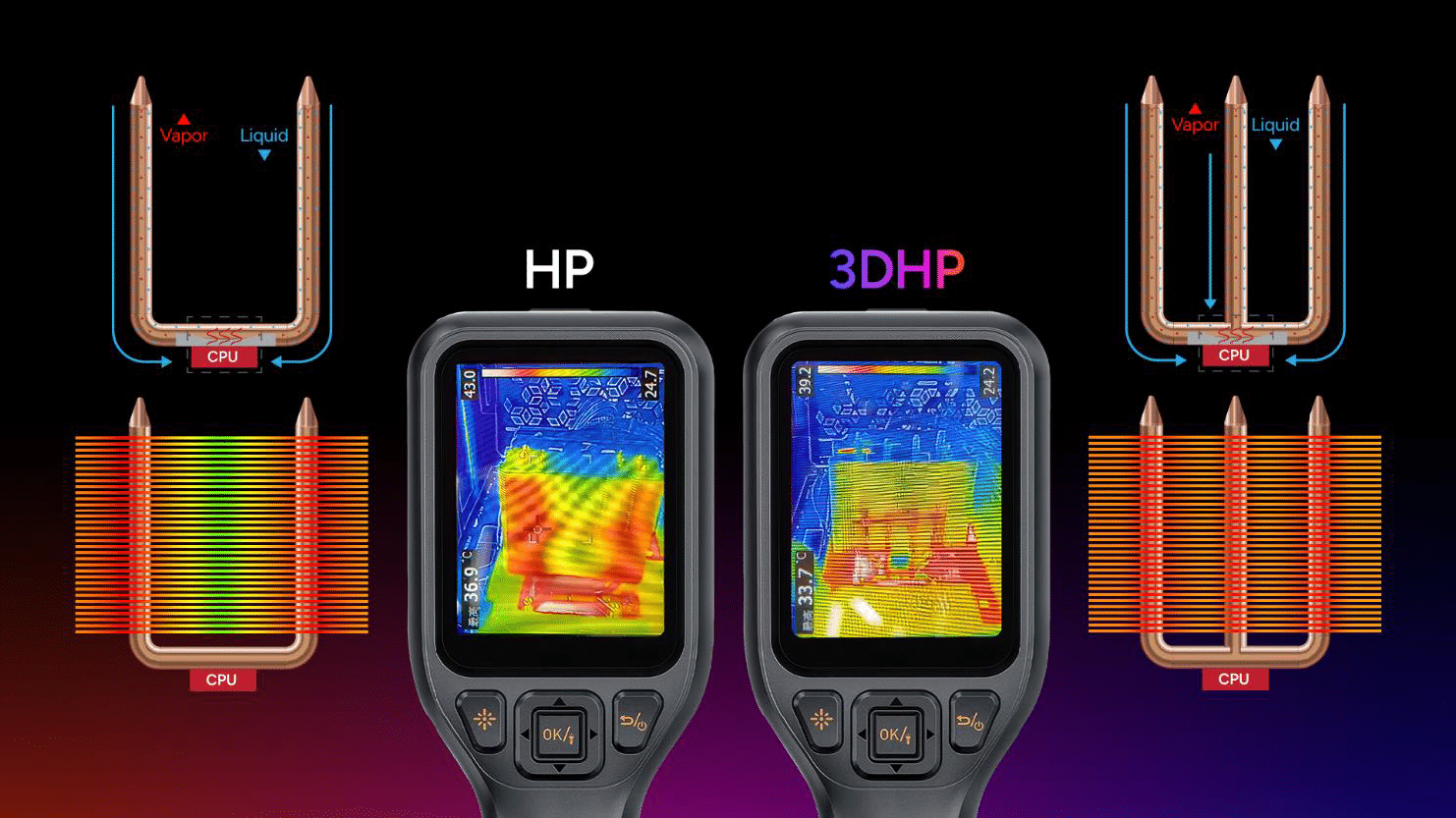

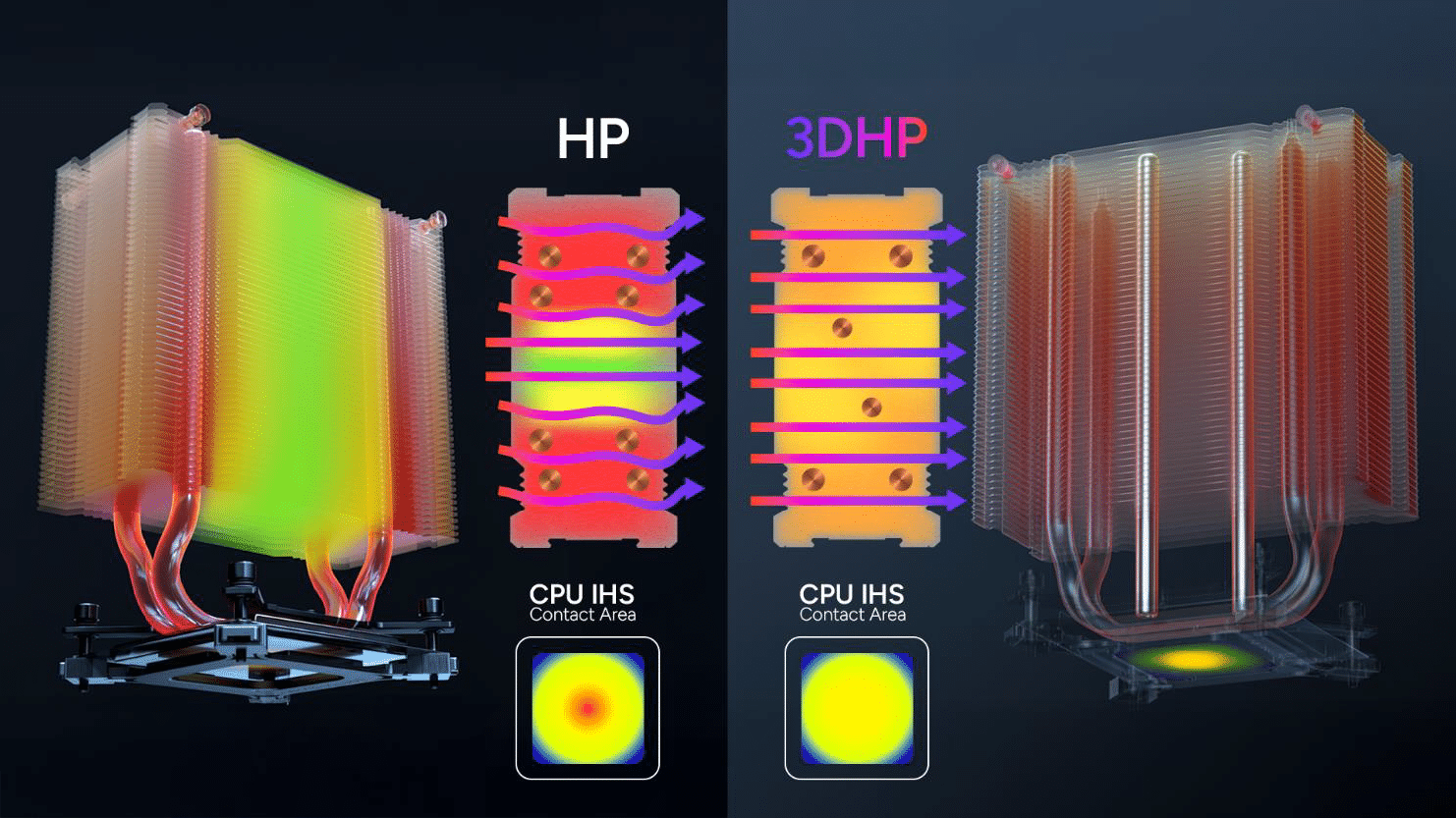

3DHP adds extra heat pipe ends and T-joints to pull heat from areas a standard U-pipe misses and to speed liquid return. By expanding pickup and return paths, it boosts effective heat transfer. In controlled tests, a 2-pipe 3DHP layout can meet the temperature targets of typical 4-pipe coolers.

The additional pipe end is strategically placed to counter CPU heat spots and still balance the performance along the entire pipe. According to CM’s claims, since 3DHP technology uses fewer pipes, the fin stack is less congested, and airflow can be smoother, which helps reduce noise.

Key Advantages of the 3DHP technology (Less is More). I used CM’s descriptions for the following on purpose, but I also provide my take in the paragraph after.

- Less reliance on extra heatpipes. More performance from more innovative design.

- Less compromise. More reliability.

- Less turbulence in the fin stack. More quiet cooling.

Cooler Master states the three advantages above. I can understand that fewer heatpipes can indeed increase reliability, since fewer things can go wrong. Still, the fact is that once the final product is out of the production line, very few things can break a heatpipe since it doesn’t have any moving parts except for the liquid inside.

Regarding the reduced turbulence in the fin stack because of fewer heatpipes. But you still have two tubes in the middle, since each 3DHP heatpipe actually has three tubes now in the finstack, instead of only two. So in essence, two 3DHP heatpipes have the same tubing in the finstack as three “normal” heatpipes. I think CM’s marketing should use smarter marketing terms to explain the advantages of 3DHP technology.

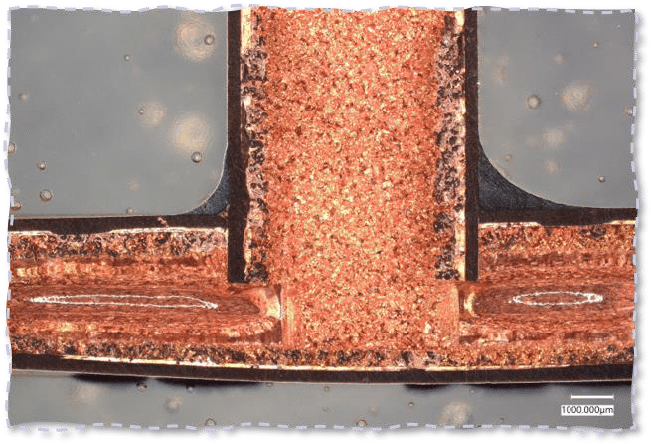

In the provided review guide, CM also explains how 3DHP is made, but I believe this is too much for the terms of a product review. The key point is that, according to CM, the manufacturing of 3DHP is a pain because it uses heat pipes with an additional end and a T-style junction to move heat more effectively through the cooler. Building those joints is tough since heatpipe walls are only 0.3 to 0.4 mm thick, so forming and sealing a circular connection without leaks or deformation requires custom tooling and tightly controlled processes. The joint must hold a vacuum, keep the working fluid inside, and preserve the internal wick or grooves so the two-phase loop can keep cycling.

The photo above is a real 3DHP T-joint. The cutaway shows how tight the tolerances are and why precise tooling and manufacturing experience are required to build this reliably for mass production.

What I need you to remember from all above, in case anyone asks you (LOL), is the following:

Cybenetics Coolers DatabaseAccording to Cooler Master, 3DHP keeps the heat-pipe approach and focuses on efficiency inside each pipe, instead of adding more pipes, 3DHP asks each pipe to do its job better. 3DHP lowers measured thermal resistance versus a conventional pipe of the same diameter. In practical terms, coolers using 3DHP can hit the same temperature targets as “plain” coolers but with fewer heat pipes.

- Product Number: Hyper 212 3DHP Black (ARGB)

- Socket Support: Intel LGA 1851/1700/1200/115x

- Socket Support: AMD AM5/AM4

- Heat pipes: 2x 3DHP (8mm diameter)

- Base Material: Copper

- Number of Fans: 1x CM Mobius 120 (ARGB)

- Fan Dimensions: 120×120×25 mm

- Bearing Type: Loop Dynamic Bearing

- Fan Speed: 0—2050 RPM (+-10%)

- Fan Airflow (Max): 63.1 CFM

- Fan Air Pressure (Max): 2.69 mmH2O

- Fan MTTF: ≧ 200,000 hrs

- Fan Noise Output Max: 22.6 dBA

- Fan Connector: 4-pin PWM

- Dimensions with fan (LxWxH): 133mm x 86mm x 158mm

- Weight (with fan): 631g

- Street Price (excl. VAT): $30

- Warranty: 5 years

- Product Number: V4 Alpha 3DHP Black

- Socket Support: Intel LGA 1851/1700/1200/115x

- Socket Support: AMD AM5/AM4

- Heat pipes: 2x 3DHP (8mm diameter)

- Base Material: Copper

- Fans: CM Mobius 120 (2050 RPM) / CM Mobius 120 (1800 RPM)

- Fan Dimensions: 120×120×25 mm

- Fan Daisy Chain: No

- Bearing Type: Loop Dynamic Bearing

- Fan Speed: 0—2050 RPM (+-10%) / 0-1800 RPM (+-10%)

- Fan Airflow (Max): 63.1 CFM / 50.5 CFM

- Fan Air Pressure (Max): 2.69 mmH2O / 1.77 mmH2O

- Fan MTTF: ≧ 200,000 hrs

- Fan Noise Output Max: 22.6 dBA / 20 dBA

- Fan Connector: 4-pin PWM

- Dimensions with fans (LxWxH): 133mm x 114mm x 161mm

- Weight (with fans): 917g

- Street Price (excl. VAT): $40

- Warranty: 5 years