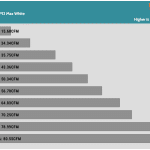

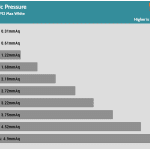

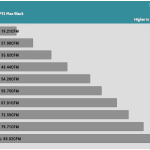

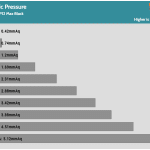

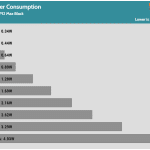

Performance – Max & Speed Percentage

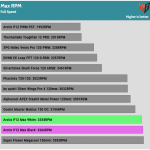

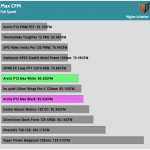

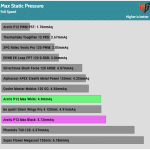

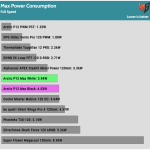

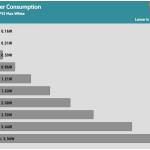

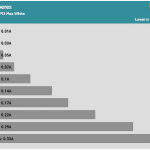

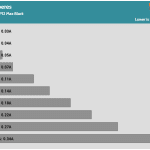

Max RPM, CFM, Pressure & Power

The Black (DBB) version achieves higher airflow and static pressure than the White (FDB) model. You have to also check the normalized noise tests, though, since you won’t have these fans running at full speed in your system.

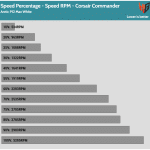

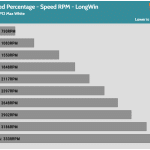

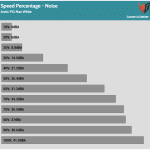

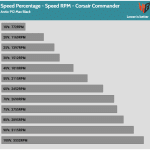

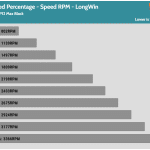

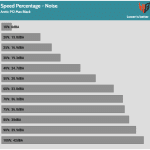

10-100% Fan Speed Percentage

Since most fan control ICs don’t apply precisely the percentage of RPM speed that you want (e.g., 50% PWM for a 2000 RPM fan should be 1000 RPM), I used to find the fan’s maximum speed and then dial directly the fan speeds that corresponded to 10%, 20%, and so on of its maximum rated speed. I decided to stop doing that. So from now on, in all of my fan evaluations, I will dial the corresponding PWM value in 10% steps to also check how accurate its fan controller is and for my noise results to align with the airflow and static pressure results from the Longwin apparatus where I don’t use RPM but PWM control for all testing.

The double ball bearing model is gone in the US. Arctic decided to change it to FDB.

I saw. I can no longer find P12 Max with double ball bearing, whether in the black or white version. That is, the black one is now FDB too!

Black: https://www.arctic.de/en/P12-Max/ACFAN00280A

White: https://www.arctic.de/en/P12-Max/ACFAN00293A

Note that the bearing is the same (double ball bearings) in both colorways. Is it the end of the double ball bearing?

I guess, the metal screeching at lower RPM caused a lot of complaints 😛

First of all, many thanks Aris!

Well, I was expecting bigger difference at lower RPMs. In the higher I expected very similar results, as it is, because the main source of noise, which covers other sounds, is created by a moving air mass that radiates a sound wave into the environment. And since the geometry of propeller is the same, there should be no major differences.

This 2nd DBB fan is not so disturbing at 10% (although it’s very near) as the 1st DBB (spike at 5 kHz). However, at 25% it is even more annoying than 1st one because of the harmonics/resonance, which starts between 2nd and 3rd second in the recording.

FDB has much nicer sound at 10% and 25% PWM level.

One note: I have one hypothesis as to why the 1st DBB has higher power consumption than the 2nd. The spike at 5 kHz reminds me of grinding/scraping metal on metal. The bearings may not be sufficiently lubricated, or the tolerance of the bearing balls is not tight enough … but its only a guess 😀

for sure there was something wrong with the first sample, since its peak RPM on the longwin were also off.