Test Methodology

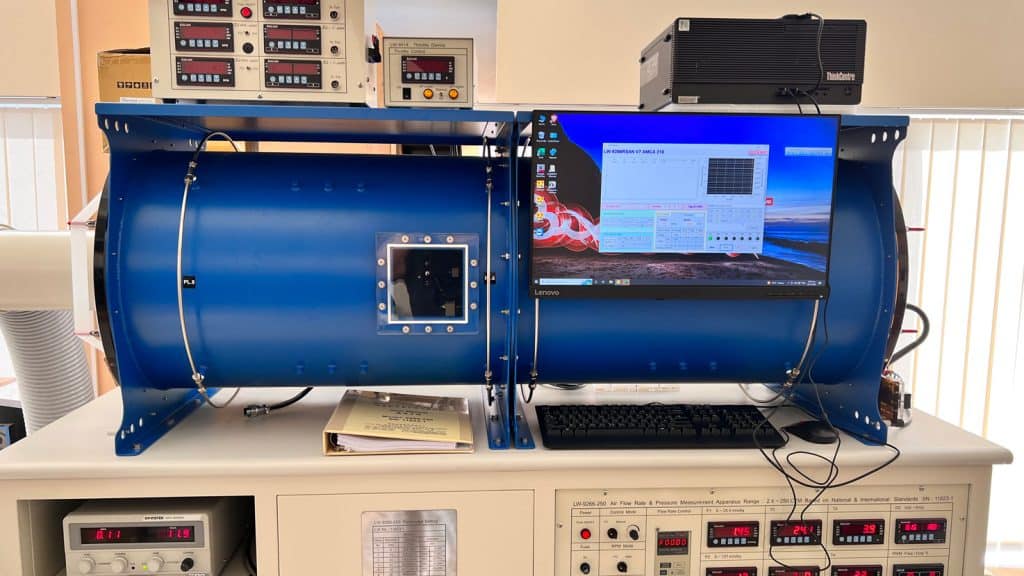

I use an LW-9266 Fan PQ performance measurement apparatus to evaluate cooling fans. This is a highly sophisticated scientific instrument made in Taiwan by Long Win.

Fan Testing Machine Technical Specifications:

- Manufacturer: Long Win Science & Technology Corporation

- Air Flow Rate: 2.4 – 250 CFM

- Accuracy of Air Flow Rage: <3.5% INFS

- Repeatability error: < 2%

- Static pressure: 0-20mmAq (100mmAq with the high static pressure throttle device)

- Overall Dimensions: 0.7 (W) x 2.2 (L) x 1.6 (H) m

- Power Source: 220VAC, 5A, Single Phase, 50/60Hz

- Based on Standards: ISO 5801-2007, AMCA 210-0, ASHRAE 51-2007, IEC 61591-2005, GB/T 1236-200

Besides the Long Win machine, I also use the following equipment.

Testing Equipment:

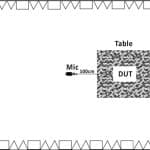

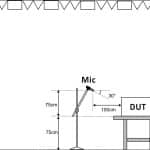

- Noise Test Environment: Hemi-Anechoic Chamber with 6 dB(A) noise floor

- Conditions: 25 (+-2) degrees Celsius, 40-50% humidity

- Sound Analyzer: Bruel & Kjaer 2270-S G4

- Microphone: Bruel & Kjaer Type 4955-A

- Mic Calibrator: Bruel & Kjaer Type 4231

- Data Logger: Picoscope TC-08

Pages:

The double ball bearing model is gone in the US. Arctic decided to change it to FDB.

I saw. I can no longer find P12 Max with double ball bearing, whether in the black or white version. That is, the black one is now FDB too!

Black: https://www.arctic.de/en/P12-Max/ACFAN00280A

White: https://www.arctic.de/en/P12-Max/ACFAN00293A

Note that the bearing is the same (double ball bearings) in both colorways. Is it the end of the double ball bearing?

I guess, the metal screeching at lower RPM caused a lot of complaints 😛

First of all, many thanks Aris!

Well, I was expecting bigger difference at lower RPMs. In the higher I expected very similar results, as it is, because the main source of noise, which covers other sounds, is created by a moving air mass that radiates a sound wave into the environment. And since the geometry of propeller is the same, there should be no major differences.

This 2nd DBB fan is not so disturbing at 10% (although it’s very near) as the 1st DBB (spike at 5 kHz). However, at 25% it is even more annoying than 1st one because of the harmonics/resonance, which starts between 2nd and 3rd second in the recording.

FDB has much nicer sound at 10% and 25% PWM level.

One note: I have one hypothesis as to why the 1st DBB has higher power consumption than the 2nd. The spike at 5 kHz reminds me of grinding/scraping metal on metal. The bearings may not be sufficiently lubricated, or the tolerance of the bearing balls is not tight enough … but its only a guess 😀

for sure there was something wrong with the first sample, since its peak RPM on the longwin were also off.