Scientists in Japan have taken a big step toward the “ultimate” rechargeable battery: the lithium-air (or lithium-oxygen) cell. These batteries are prized because they can store far more energy than today’s lithium-ion cells, while staying exceptionally light, exactly what future electric cars and aircraft need.

What’s New?

A joint team from Japan’s National Institute for Materials Science (NIMS) and carbon specialist Toyo Tanso has developed a new type of carbon electrode that fixes three long-standing problems with lithium-air batteries:

- Low power output

- Short lifespan

- Poor scalability to larger sizes

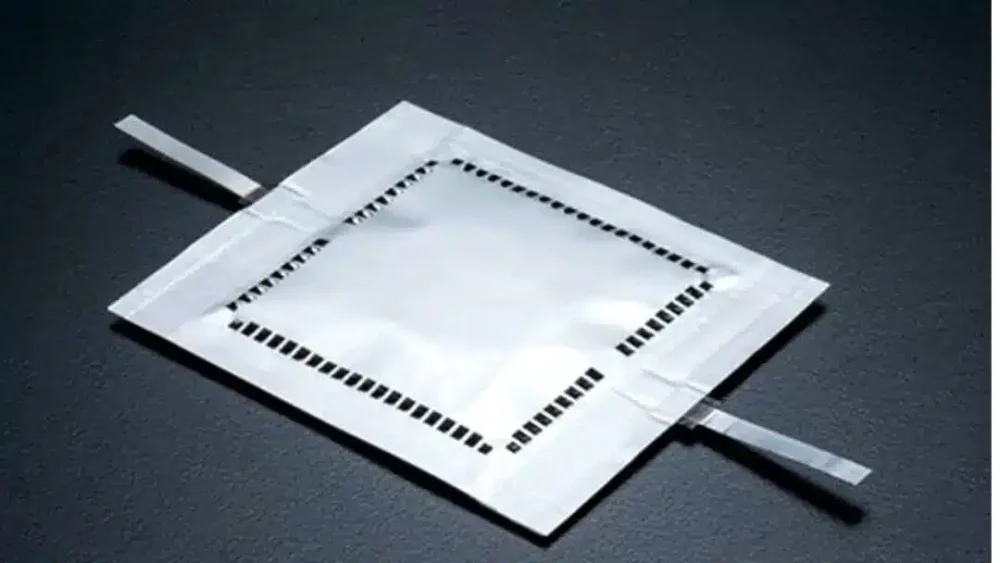

Using this electrode, they built a 1-Wh (1 Watt-hour) lithium-air pouch cell with a 4 × 4 cm electrode and showed that it can run stably for more than 150 charge–discharge cycles at a relatively high current. Just as important, they’ve also demonstrated how to manufacture much larger electrodes (10 × 10 cm and up), which is key for real products.

How The New Electrode Works

Lithium-air batteries rely heavily on the structure of the positive electrode, which is usually carbon. It needs:

- Plenty of pores so oxygen can reach the reaction sites

- Enough stability to survive many charge cycles

- A scalable way to manufacture it

Earlier designs used very porous carbon, but the pore structure was difficult to control, unstable, and difficult to mass-produce.

The new work solves this by creating a “hierarchically porous graphitized carbon membrane”:

- Mesoporous carbon powder is made using magnesium oxide (MgO) as a removable template.

- The carbon is processed into a self-supporting membrane using standard “doctor-blade” slurry casting.

- A technique called non-solvent-induced phase separation (NIPS) introduces larger pores, allowing oxygen to move freely through the electrode.

At the same time, the carbon is treated at very high temperatures, so its internal structure becomes more graphite-like (highly ordered carbon). This:

- Improves electrical conductivity

- Reduces unwanted surface oxygen groups that can cause side reactions

- Boosts durability and cycle life

The result is a light, thin, sponge-like carbon sheet that allows oxygen and ions to move freely while remaining strong and stable.

What We Get

- Higher energy density: Lithium-air cells have already demonstrated over 500 Wh/kg at the lab scale, far above most lithium-ion batteries, which struggle to exceed 300 Wh/kg.

- Better power and lifespan: The new electrode design helps the battery deliver more power (for applications like EV acceleration or electric vertical takeoff) and withstand many more charge cycles.

- Scalable manufacturing: The materials and processes used (templated carbon, slurry casting, NIPS) are compatible with existing battery production techniques, making industrial use more realistic.

What It Could Mean For EVs And Electric Flight

If this technology continues to improve and reaches commercial maturity, it could:

- Extend EV driving range dramatically without increasing battery pack weight.

- Make electric aircraft and air taxis more practical by using lighter, high-energy packs that still deliver intense bursts of power for takeoff and landing.

- Reduce energy use and cooling needs in data centers and advanced electronics, where ultra-efficient, high-density batteries are also valuable.

We’re still years away from seeing lithium-air packs in commercial cars or planes, but this work shows that large, stable, and powerful lithium-air cells are becoming technically feasible. For now, it’s a key proof-of-concept that the “battery after lithium-ion” may no longer be just a theory.