Part Analysis

| General Data | |

| Manufacturer (OEM) | CWT |

| Platform | CSA |

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV, 1x Power Integrations CAP200DG (X Capacitor Discharge IC) |

| Inrush Protection | NTC Thermistor SCK-207R0 (7 Ohm @ 25°C) & Relay |

| Bridge Rectifier |

2x Yangzhou GBUL1506 (600V, 15A @ 100°C)

|

| APFC MOSFETs |

3x PingWei PWE120N65SFMF (650V, 20A @ 100°C, Rds(on): 120mOhm)

|

| APFC Boost Diode |

CRMicro CRXI08D065G2 (650V, 8A @ 165°C)

|

| Bulk Cap(s) |

2x Rubycon (400V, 390uF each or 780uF combined, 2000h @ 105°C, MXE)

|

| Main Switchers |

4x Way-On WML26N65F2 (650V, 10.5A @ 100°C, Rds(on): 0.21Ohm)

|

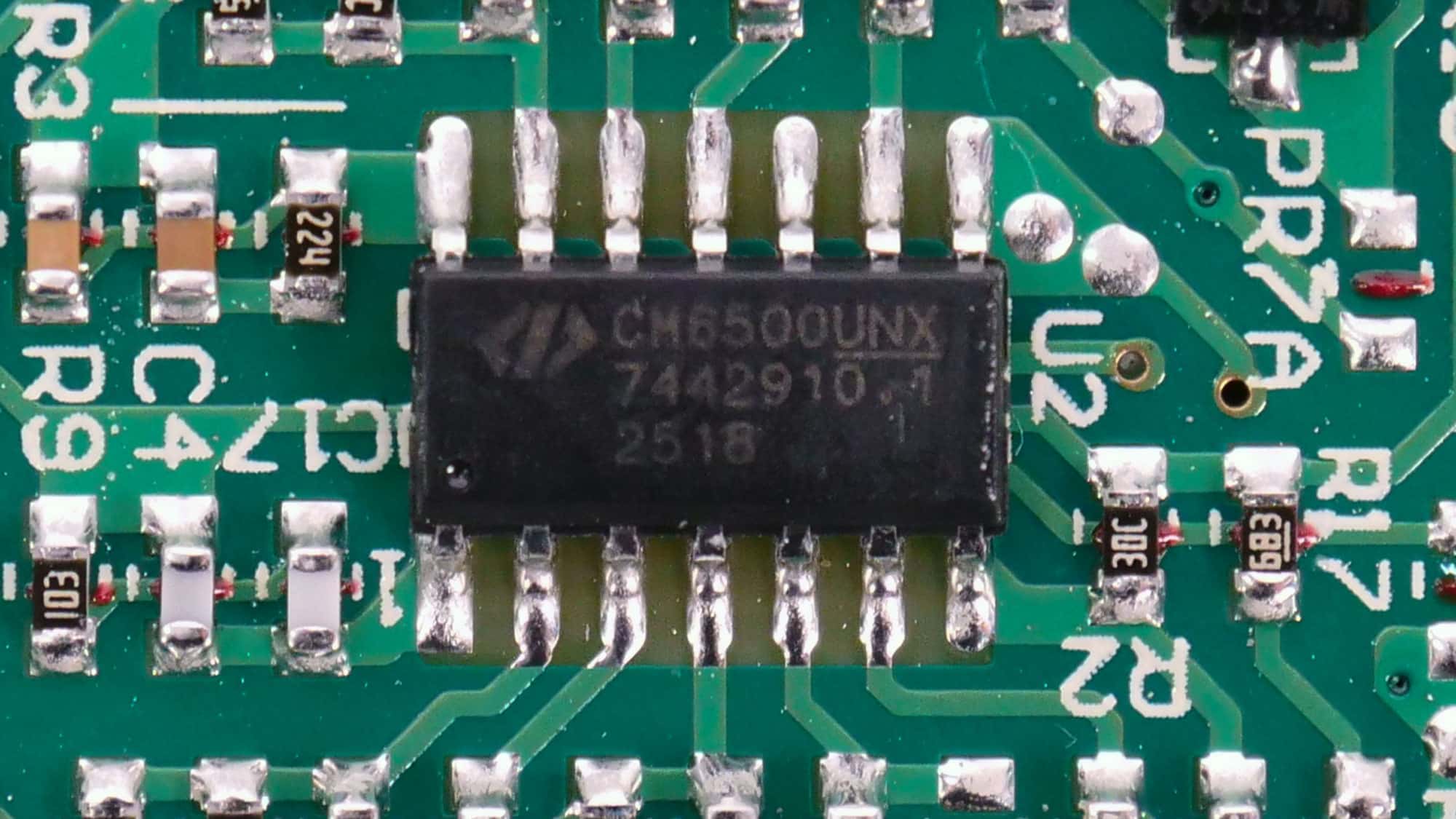

| APFC Controller | Champion CM6500UNX |

| Resonant Controller |

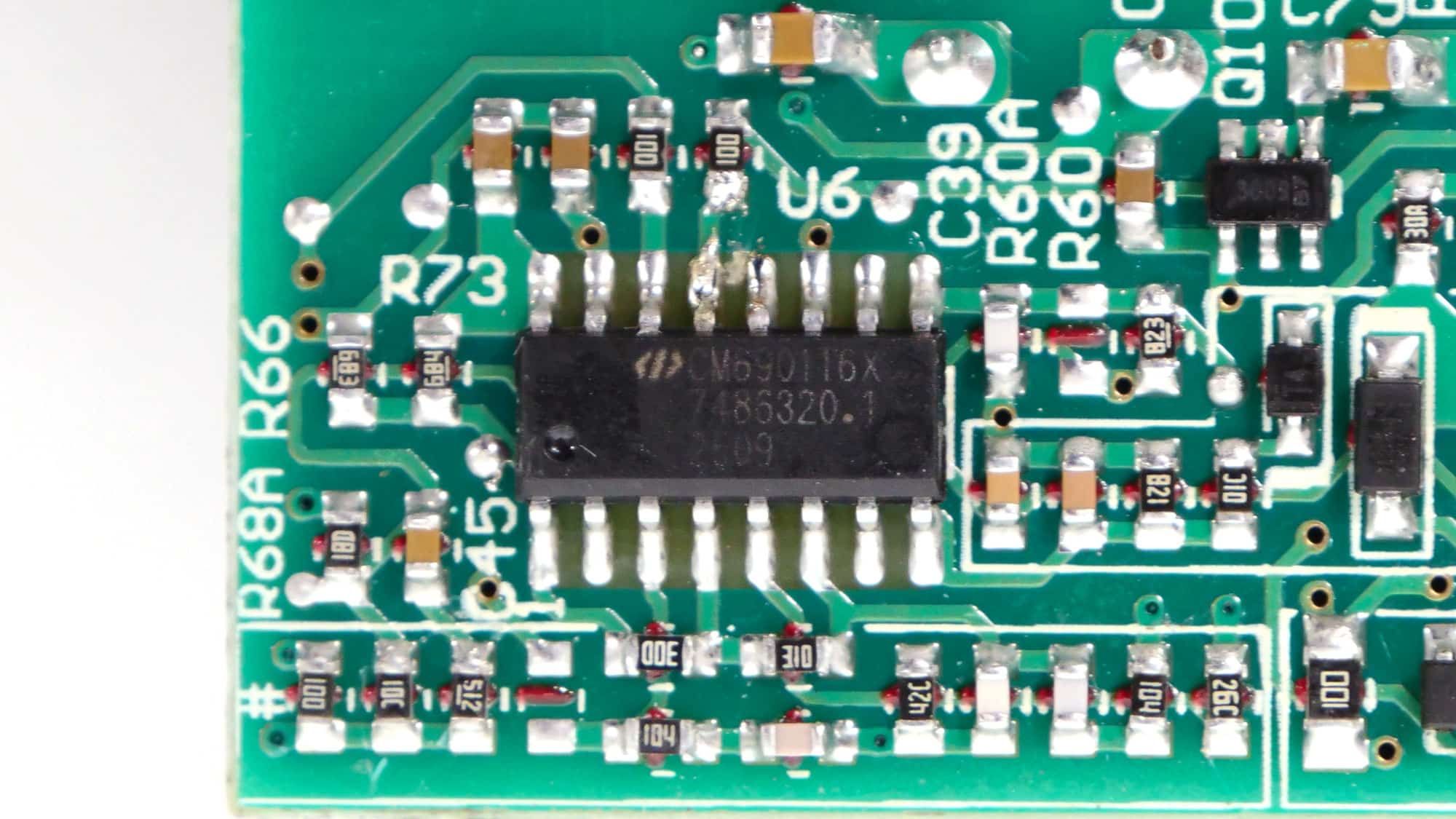

Champion CM6901T6X

|

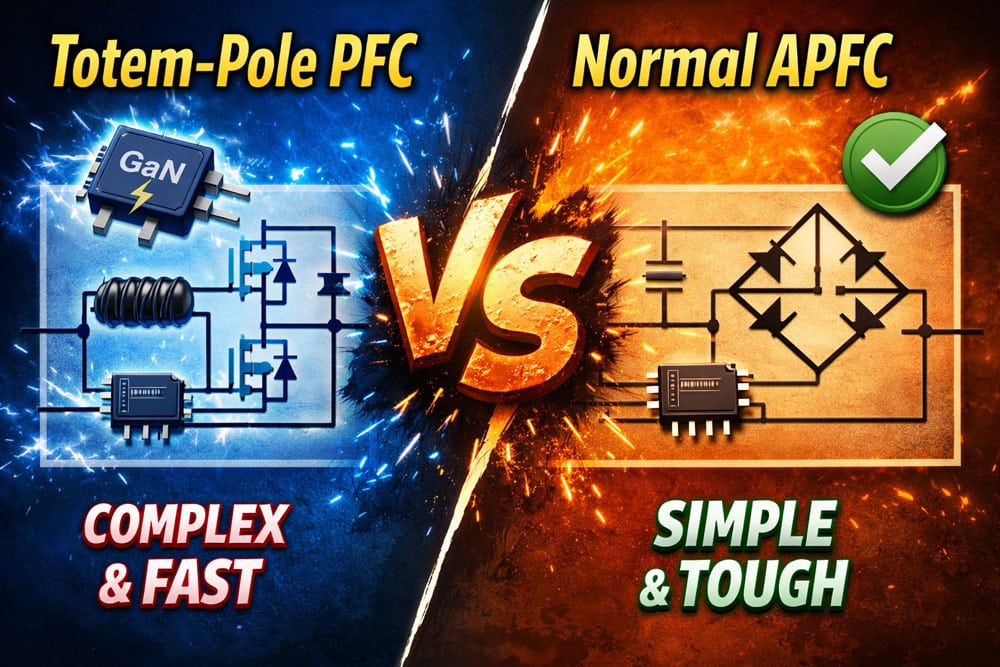

| Topology | Primary side: APFC, Full-Bridge & LLC Resonant Converter Secondary side: [12V] Synchronous Rectification & [Minor Rails] DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 8x PingWei PWC013N04ES (40V, 155A @ 100°C, Rds(on): 1.3mOhm) |

| 5V & 3.3V | DC-DC Converters: 4x UBIQ Semi QM3054M6 (30V, 61A @ 100°C, Rds(on): 4.8mOhm) PWM Controller(s): ANPEC APW7159C |

| Filtering Capacitors | Electrolytic: 2x Nippon Chemi-Con (@ 105°C, W) 2x Rubycon (3-6,000 @ 105°C, YXS) 3x Rubycon (6-10,000 @ 105°C, ZLH) 2x Rubycon (4-10,000 @ 105°C, YXF) Rubycon (4-10,000 @ 105°C, YXJ) Nichicon (4-10,000 @ 105°C, HE(M)) Polymer: 10x Nippon Chemi-Con, 13x FPCAP, 2x no info |

| Supervisor IC | NDP NDP8313iKC |

| Fan Model | TT-13525 / CWT13525H12F-9 (135mm, 12V, 0.4A, Fluid Dynamic Bearing Fan) |

| 5VSB Circuit | |

| Rectifier (Low Side) |

Dongke DK5V45R10V (45V, 10mOhm)

|

| Standby PWM Controller |

KP22306AWG

|

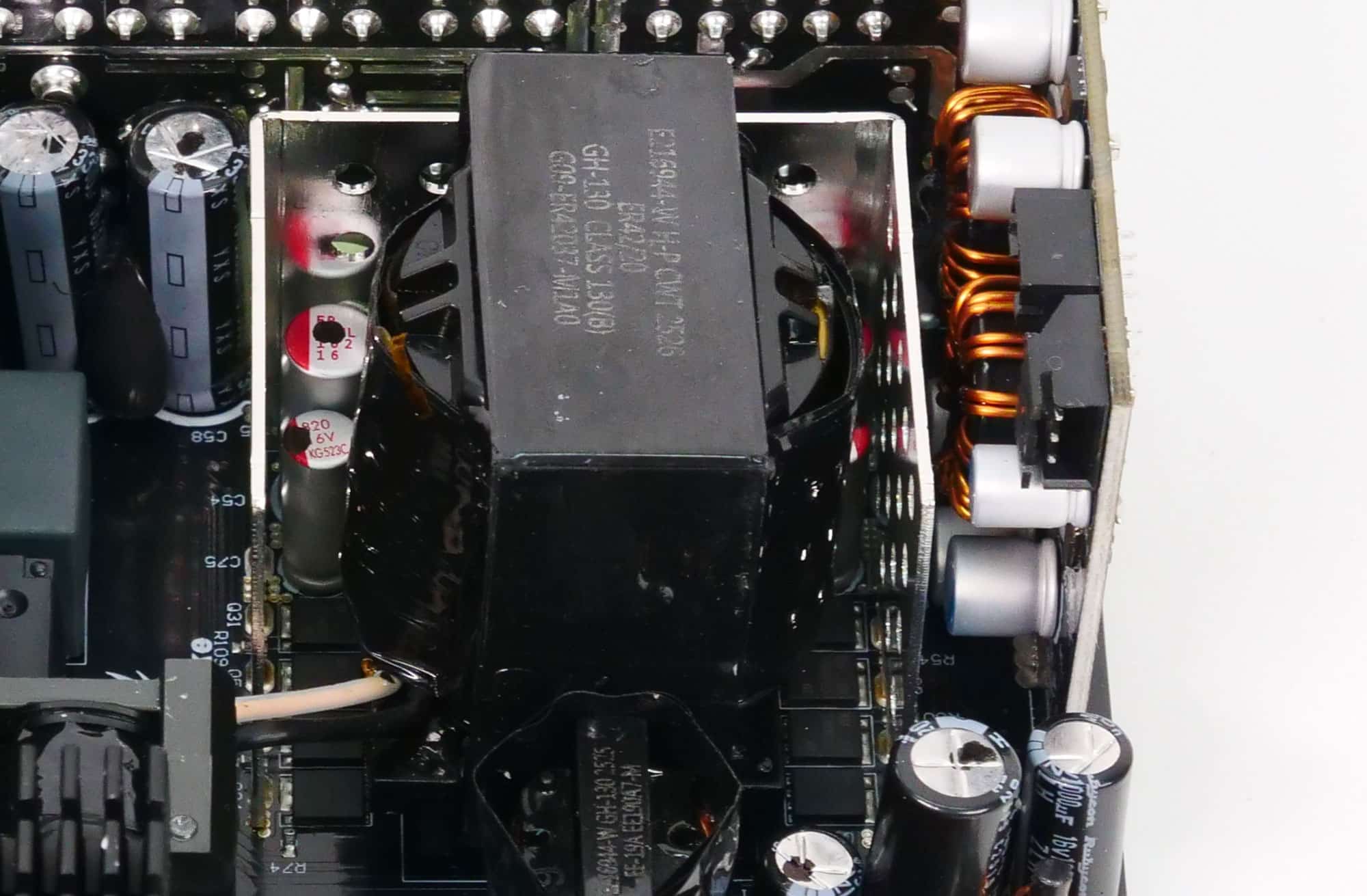

This is the same platform used in the PT 1200 model, with some component changes due to the lower maximum power output. CWT provides the platform, featuring a contemporary design with a full-bridge topology on the primary side and an LLC resonant converter for reduced energy losses. The PCB is compact, and to keep the parts cool without overspinning the fan, CWT used large heatsinks on the primary side. Typically, for a CWT design, the heatsinks on the secondary side are way smaller. Basically, the secondary’s side heatsink is a plate surrounding three sides of the main transformer, providing cooling and acting as a common-mode EMI shield. The same aluminum cover of the main transformer also offers limited high-frequency magnetic shielding.

To keep costs low, CWT didn’t use branded FETs from Infineon or Vishay but went with Chinese brands that will do just fine. On the other hand, for the electrolytic capacitors, it chose well-known and expensive brands. Moreover, the cooling fan is provided by CWT, which decided to make its own rather than rely on other manufacturers. This is a wise move!

The transient filtering stage contains all the necessary components to block both incoming and outgoing EMI emissions. Typically, it starts at the AC receptacle and continues on the main PCB. It also includes a discharge IC for its X caps to provide a slight efficiency boost.

There is an MOV to protect from voltage surges and an NTC thermistor with a resistance of 7 ohms. Moreover, a bypass relay supports the NTC thermistor.

The parallel bridge rectifiers convert the incoming AC signal to a loosely regulated DC voltage. Combined, they can handle up to 30A.

The APFC converter uses three PingWei PWE120N65SFMF FETs and a single CRMicro CRXI08D065G2 boost diode. Rubycon manufactures the bulk capacitors. Their combined capacity is 780 μF, and both are rated for 2,000 hours at 105 °C. The voltage rating is 400V, which is pretty close to the APFC’s DC bus voltage (approximately 380-400V DC). It would be better to use 420V-rated bulk caps or ideally 450V.

The APFC controller is a Champion CM6500UNX.

Four Way-On WML26N65F2 primary-switching FETs are used in a full-bridge topology, and an LLC resonant converter is employed for enhanced efficiency.

The LLC resonant controller is a Champion CM6901T6X.

The PSU’s main transformer. One of its main functions is to isolate the primary and secondary sides electrically.

Eight PingWei PWC013N04ES FETs regulate the 12V rail. They are installed on the business (top) side of the PCB. The same type and number of FETs are installed in the 1200W model!

Two DC-DC converters generate the minor rails. They use four UBIQ Semi QM3054M6 FETs. The PWM controller is an Anpec APW7159C.

Chemi-Con, Rubycon, and Nichicon provide the electrolytic capacitors. Chemi-Con and FPCAP make the polymer capacitors. There are also two polymer caps, which I couldn’t identify (the OEM).

You can find more information about capacitor performance and other specs below:

The standby PWM controller is a KP22306AWG.

Several polymers and two big electrolytic caps on the face of the modular panel form an extra ripple-filtering layer.

The supervisor IC is an NDP NDP8313iKC (OVP, UVP, SCP, PG). This is the first time I’ve encountered this supervisor IC (to the best of my knowledge), and there is nothing for it online. I will ask CWT to provide some more info on it.

The soldering quality is notably better than what I encountered in the 1200W model.

The cooling fan is a CWT13525H12F-9 that uses a fluid-dynamic bearing.

Here cybenetics reports

850w which is not very good

https://www.cybenetics.com/evaluations/psus/2580/

1000w Malfunctioning protections that don’t engage in time before the minor rails experience a huge voltage drop out of spec.

https://www.cybenetics.com/evaluations/psus/2575/

Basically i wouldnt do none of these

Any chance for review Thermaltake SFX ATX 3.1 ?

If we have it in our database sure.