Part Analysis

| General Data | |

| Manufacturer (OEM) | Andyson |

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | 1x NTC Thermistor SCK 056 (5 ohm) & Relay |

| Bridge Rectifier(s) |

2x GBU1506L (800V, 15A @ 100°C)

|

| APFC MOSFETs |

2x PingWei PWE120N65SFMF (650V, 20A @ 100°C, Rds(on): 120mOhm)

|

| APFC Boost Diode |

1x Global Power G4S06508AT (650V, 8A @ 153°C)

|

| Bulk Cap(s) |

1x Nippon Chemi-Con (400V, 680uF, 2,000h @ 105°C, KMW)

|

| Main Switchers |

2x PingWei PWE120N65SFMF (650V, 10.5A @ 100°C, Rds(on): 0.21Ohm)

|

| APFC Controller | |

| Resonant Controller |

Champion CM6901T6X

|

| Topology |

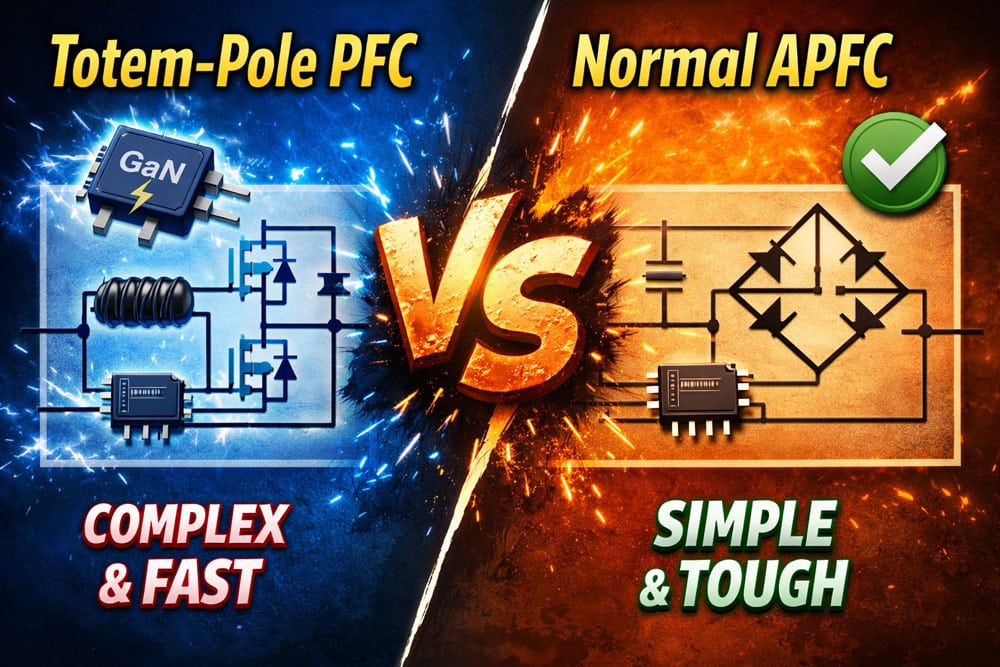

Primary side: APFC, Half-Bridge & LLC Resonant converter

Secondary side: [12V] Synchronous Rectification & [Minor Rails] DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 6x PingWei PWC012N04ES (40V, 132A @ 100°C, Rds(on): 1.2mOhm) |

| 5V & 3.3V | DC-DC Converters: 4x WayOn WMO190N03TS (30V, 120A @ 100°C, Rds(on): 2.8mOhm) PWM Controller(s): 2x Anpec APW7164 |

| Filtering Capacitors | Electrolytic: 1x Nippon Chemi-Con (2-5,000h @105°C, KZE) 1x Nippon Chemi-Con (4-10,000h @105°C, KY) 2x Nichicon (6,000h @105°C, HV(M)) 4x Rubycon (6-10,000h @105°C, ZLH) 1x Rubycon (4-10,000h @105°C, YXF) 1x Rubycon (4-10,000h @105°C, YXJ) 4x CS (2,000h @ 105°C, WR) Polymer: 17x Polycap, 2x Teapo |

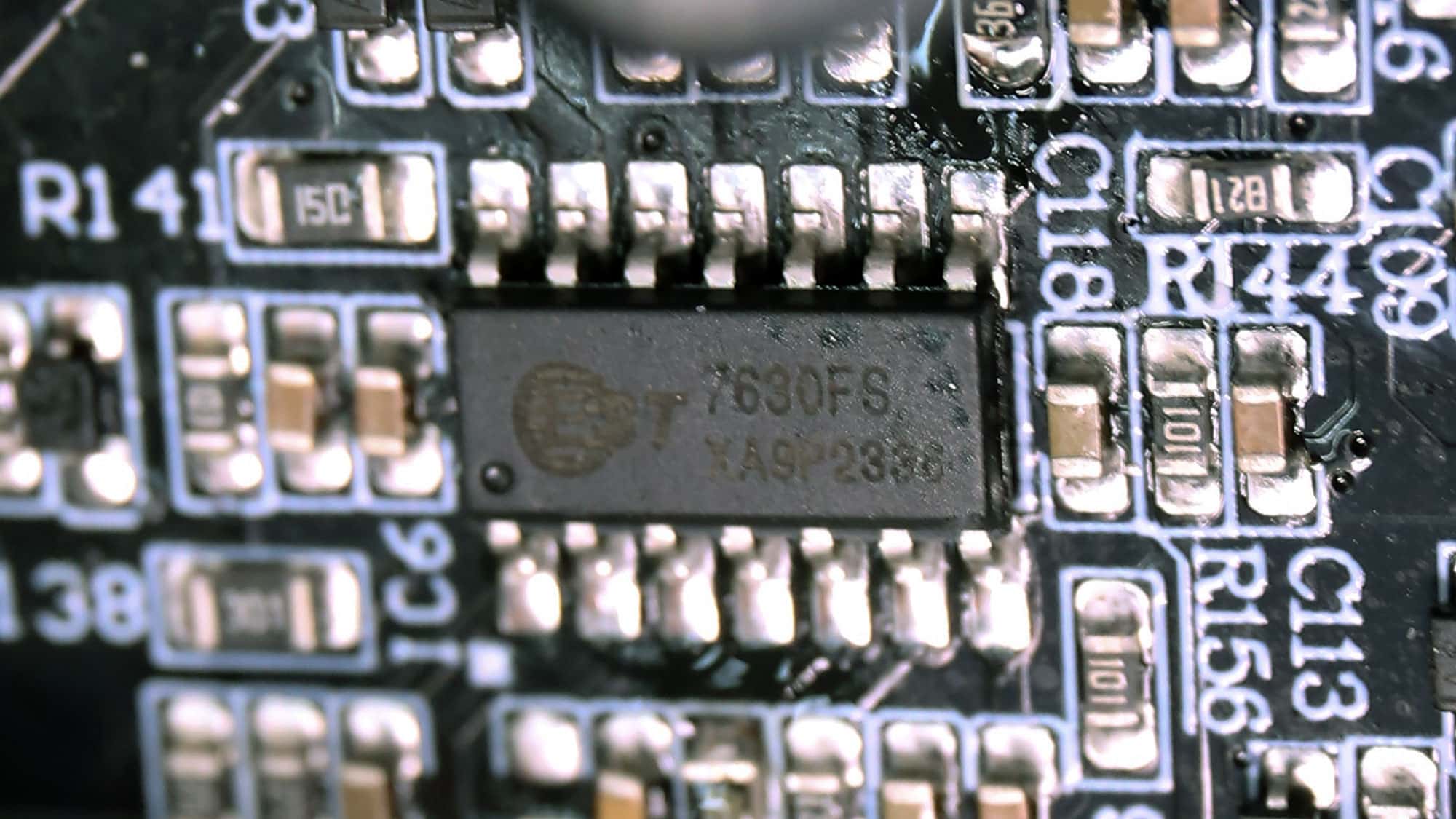

| Supervisor IC | Esthome EST.7630FS |

| Fan Model | Poweryear PY-1225H12S (120mm, 12V, 0.35A, Sleeve Bearing Fan). |

| 5VSB | |

| Rectifier | |

| Standby PWM Controller |

Esthome EST.3026M

|

Unlike the 1000W model, which uses a platform by Channel Well Technology (CWT), this one is made by Andyson. I’m unsure why SilverStone chose a different OEM for the 1000W unit, which sets it apart from the rest of the series, but I assume they had valid reasons, likely related to production costs. The fact is that Andyson has recently offered highly competitive prices to re-enter the PSU market and attract more clients.

The small PCB has a lot of empty space, as the 12V FETs are installed on a vertical board, and the same applies to the FETs that regulate the 5V rail. The 3.3V rail’s regulation circuit is installed on the business side of the main PCB. The electrolytic filtering capacitors on the secondary side are few, since Andyson mostly used polymer caps, which, however, don’t provide enough capacity to boost performance under transient loads. To wrap up the platforms’ design, on the primary side, we find an APFC converter, a half-bridge topology, and an LLC resonant converter for the primary and the 12V FETs. On the secondary side, a synchronous rectification scheme and a pair of VRMs are used for the generation of the minor rails. Unlike the 1000W model, which uses a different platform, the fan doesn’t utilize a dedicated fan controller to manage the speed profile better.

The transient filtering stage contains all the necessary components to block both incoming and outgoing EMI emissions. Typically, it starts at the AC receptacle and continues on the main PCB.

There is an MOV to protect from voltage surges and an NTC thermistor. Moreover, a bypass relay supports the NTC thermistor.

The two GBU1506L parallel bridge rectifiers can handle up to 30A together.

The APFC converter uses two PingWei PWE120N65SFMF FETs and one Global Power G4S06508AT boost diode. Chemi-Con manufactures the bulk capacitor with a capacity of 680 μF. It is rated for 2,000 hours at 105 °C. Its voltage rating is borderline at 400V, given that the APFC’s DC bus voltage is approximately 380V DC.

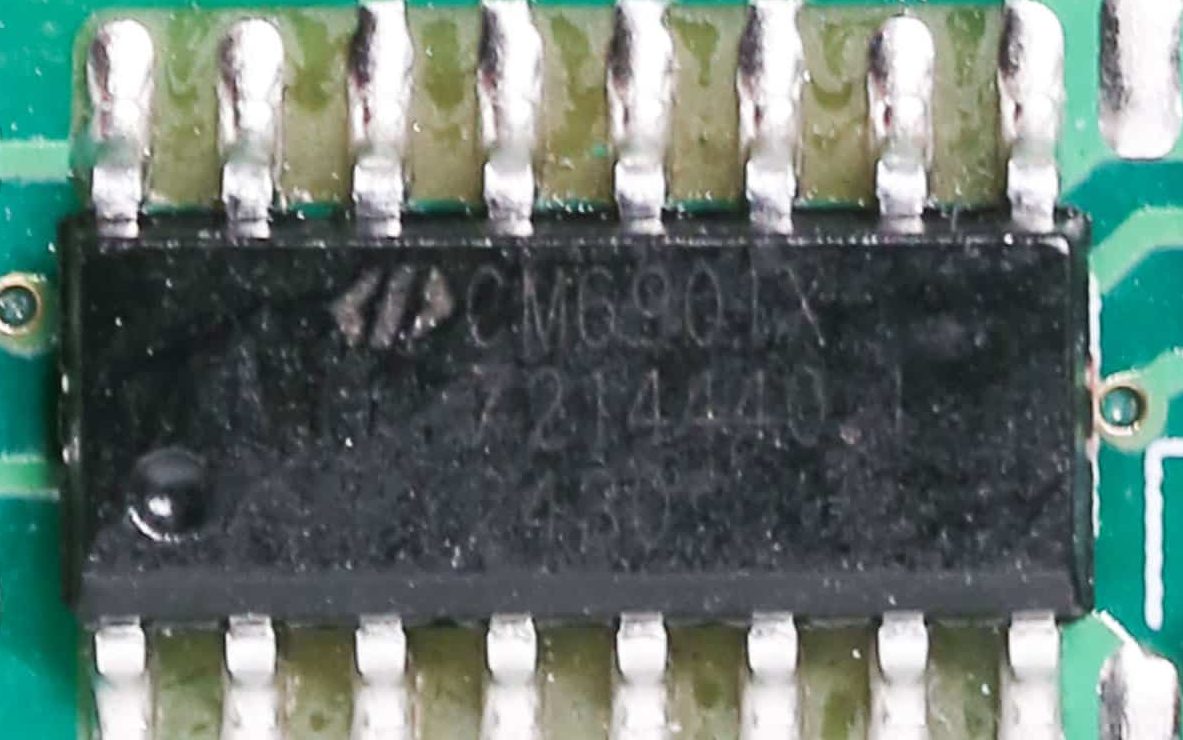

The APFC controller is a Champion CM6500UNX. A CM03AX supports it for reduced vampire power.

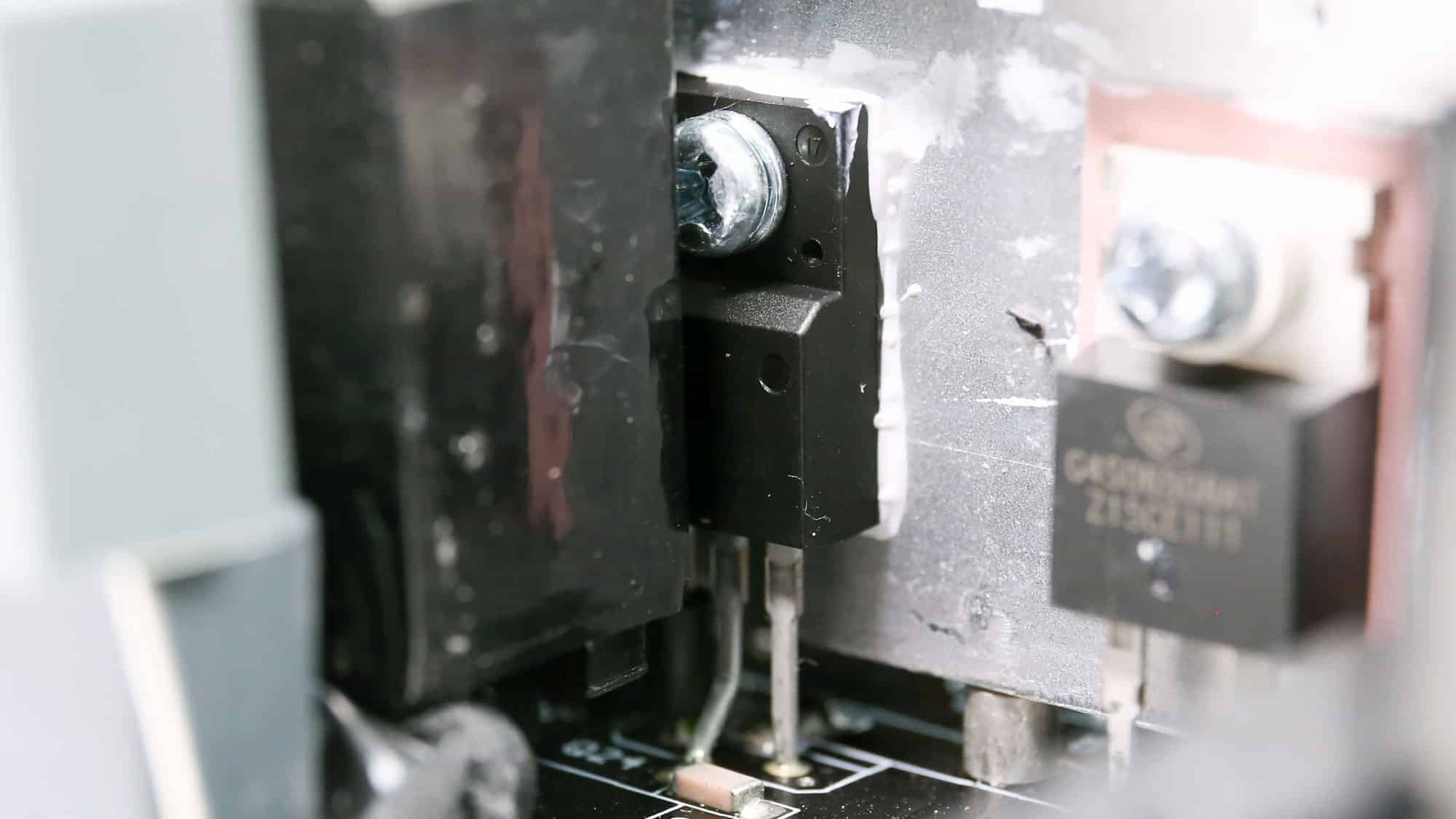

The two PingWei PWE120N65SFMF primary switching FETs are installed in a half-bridge topology, and an LLC resonant converter is used to achieve higher efficiency.

The LLC resonant controller is a Champion CM6901X.

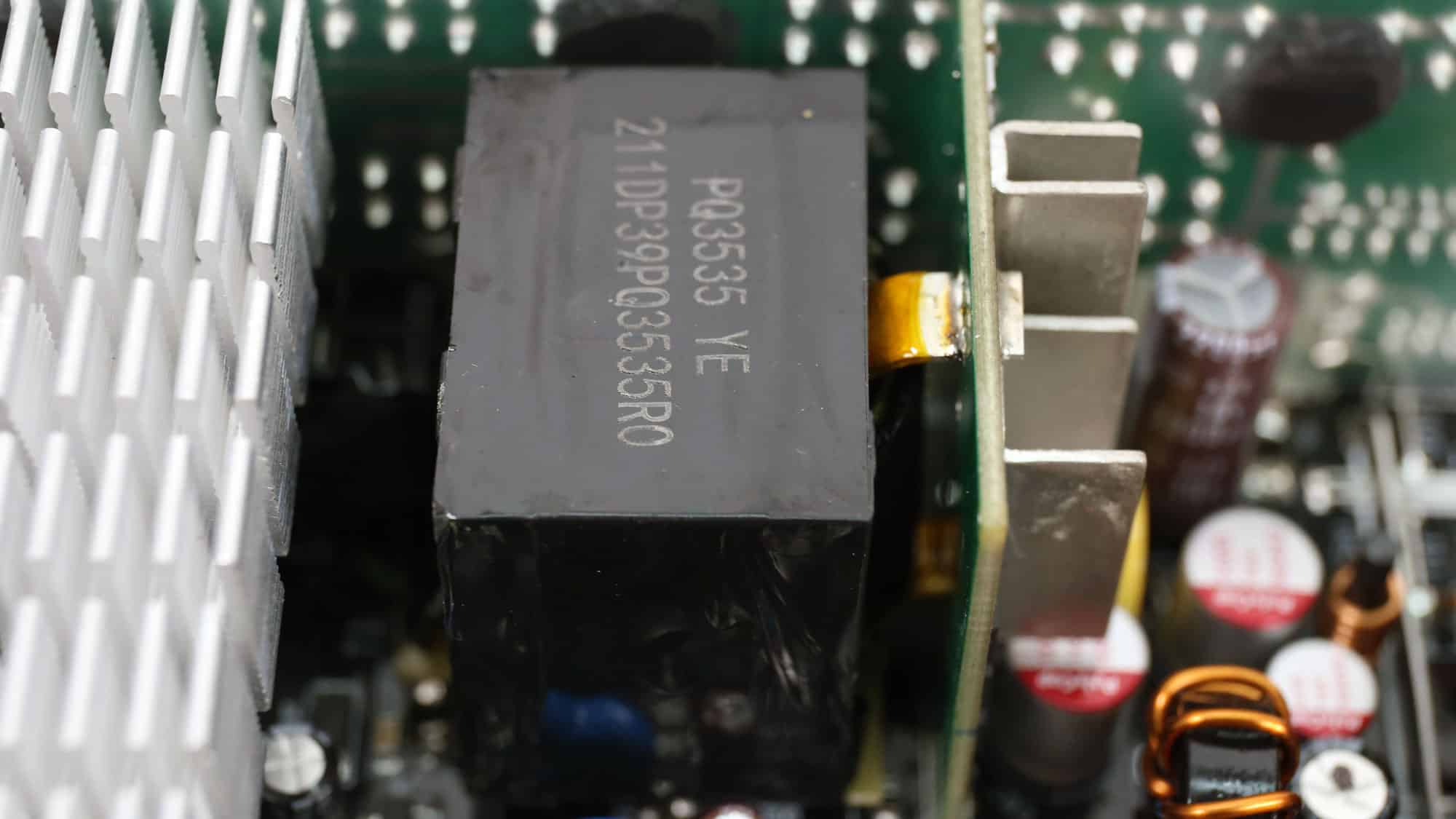

The PSU’s main transformer. One of its main functions is to isolate the primary and secondary sides electrically.

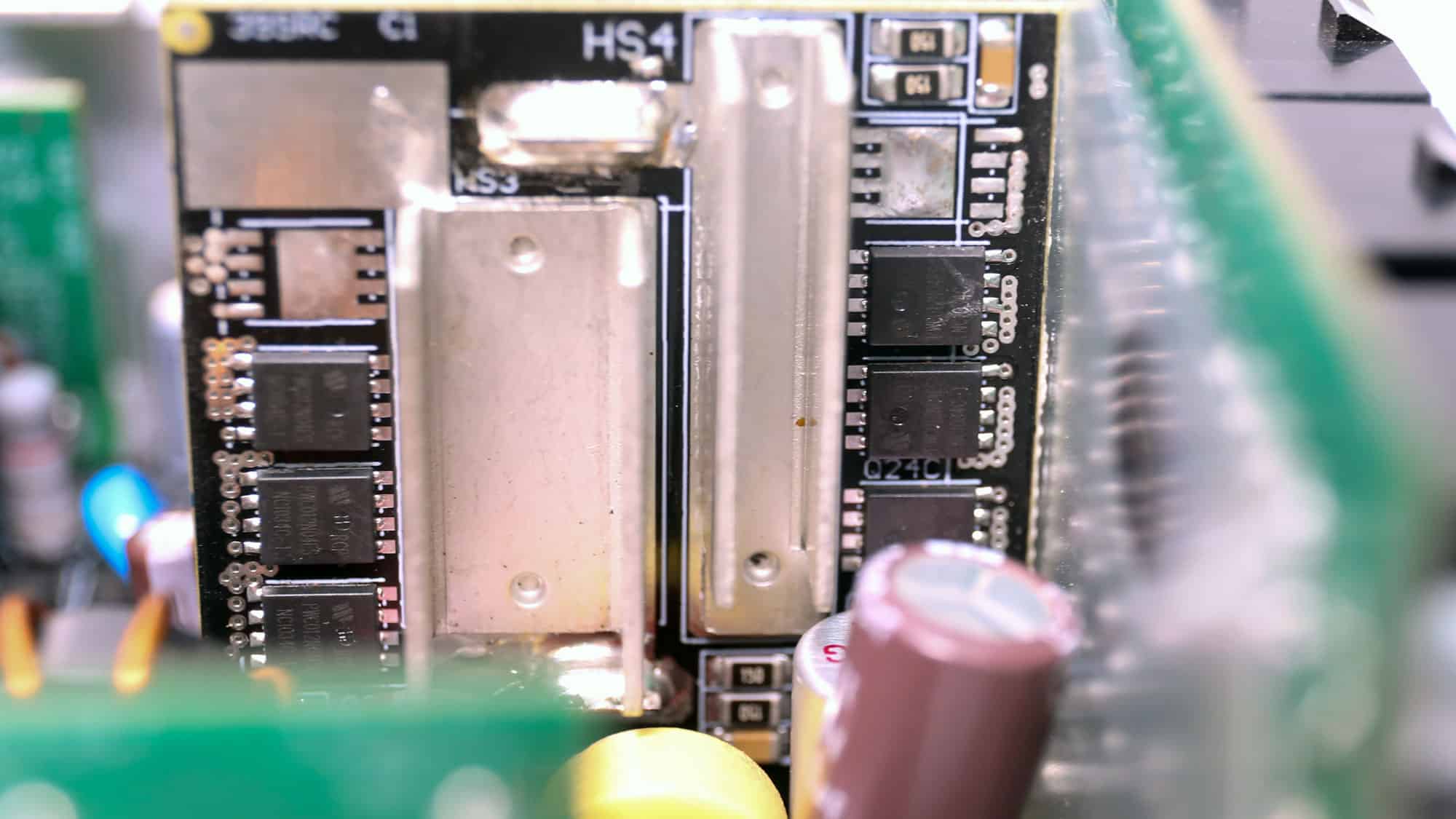

Six PingWei PWC012N04ES FETs regulate the 12V rail. They are installed on a daughter board residing next to the main transformer to minimize energy losses.

Two DC-DC converters generate the minor rails. They use four WayOn WMO190N03TS FETs and two Anpec APW7164. The reason the VRMs use a pair of controllers is because they are not in the same region. One of them, which handles the 5V rail, is on a daughter board, while the 3.3V regulation circuit is on the PCB.

Rubycon, Chemi-Con, and CS provide the electrolytic caps. The polymer caps are by Polycap and Teapo.

You can find more information about capacitor performance and other specs below:

The standby PWM controller is an Esthome EST.3026M. The primary rectifier of the standby rail is a Pingwei PS1045L.

Several polymer caps at the face of the modular panel form an extra ripple-filtering layer. There are also five electrolytic caps installed in this area.

The soldering quality is average in some areas but decent in others.

The supervisor IC is an Esthome EST.7630FS.

The cooling fan is a Poweryear PY-1225H12S, utilizing a sleeve bearing, as specified in the found specs.