Part Analysis

| General Data | |

| Manufacturer (OEM) | CWT (GPX Platform) |

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV, 1x Power Integrations CAP200DG (discharge IC) |

| Inrush Protection | 1x NTC Thermistor SCK-056 (5 ohm) & Relay |

| Bridge Rectifier(s) |

2x GBU1006 (600V, 10A @ 100°C)

|

| APFC MOSFETs |

2x WayOn WML53N60C4 (600V, 26A @ 100°C, Rds(on): 0.07Ohm)

|

| APFC Boost Diode |

1x CRMicro CRX10D065G2 (650V, 10A @ 161°C)

|

| Bulk Cap(s) |

1x Nippon Chemi-con (400V, 680uF, 2,000h @ 105°C, KMR)

|

| Main Switchers |

4x WayOn WML26N65F2 (650V, 10.5A @ 100°C, Rds(on): 0.21Ohm) &

1x Sync Power Corp SPN5003 (For no load consumption) |

| APFC Controller |

Champion CM6500UNX

|

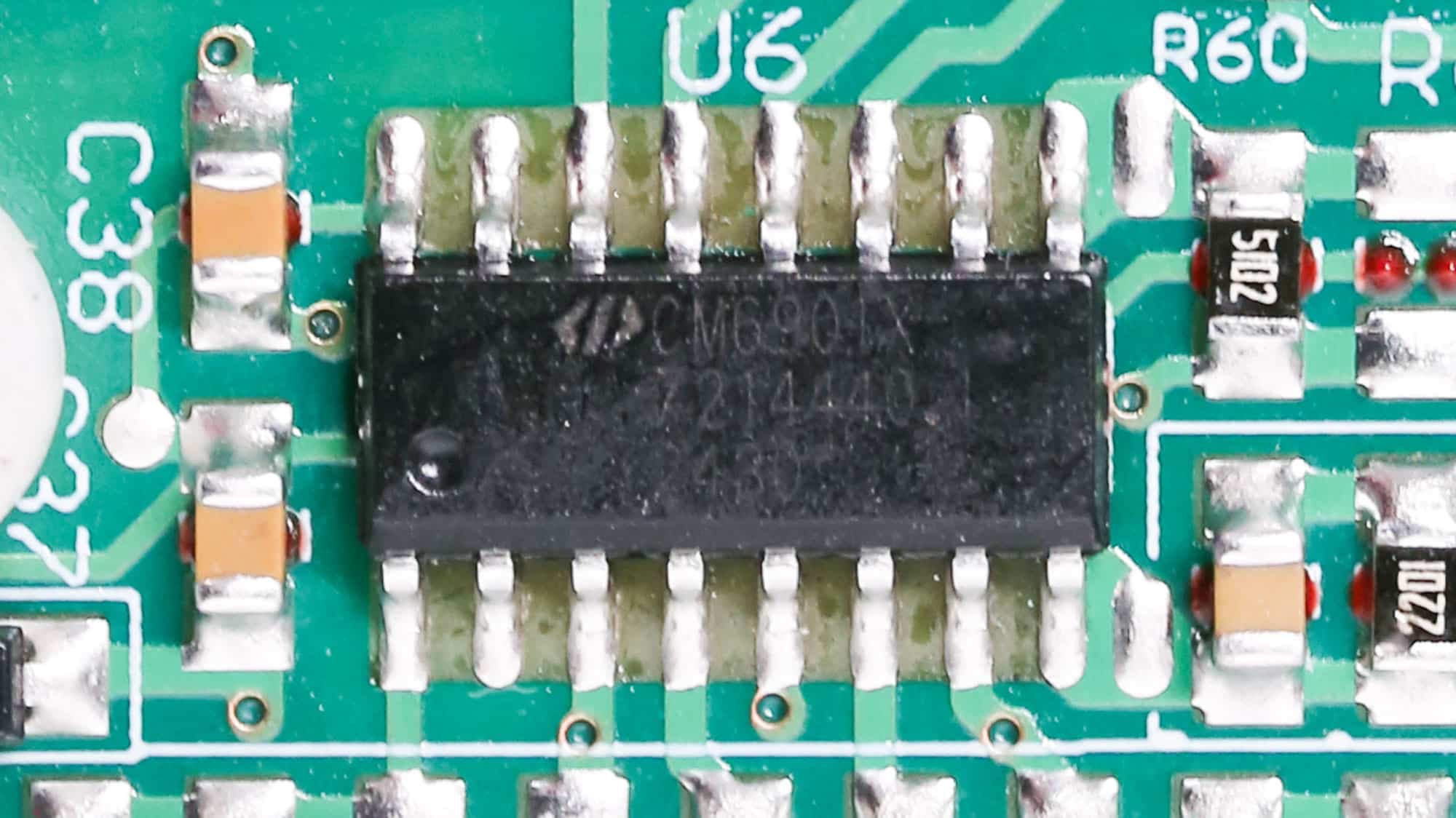

| Resonant Controller |

Champion CM6901X

|

| Topology |

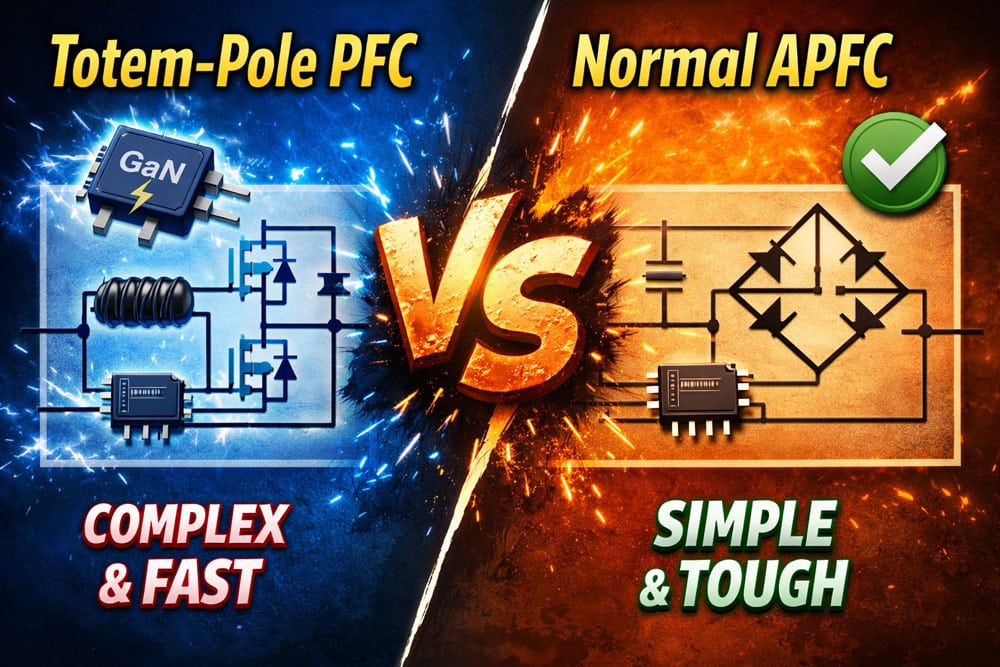

Primary side: APFC, Full-Bridge & LLC Resonant converter

Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 8x IPS FTG014N04SA |

| 5V & 3.3V | DC-DC Converters: 4x UBIQ QM3054M6 (30V, 61A @ 100°C, Rds(on): 1.7mOhm) PWM Controller(s): no info |

| Filtering Capacitors | Electrolytic: 2x Nippon Chemi-Con (105°C, W) 1x Nippon Chemi-Con (2-5,000h @105°C, KZE) 3x Nichicon (5-6,000h @ 105°C, HV) 5x Rubycon (4-10,000h @105°C, YXJ) 1x Rubycon (4-10,000h @105°C, YXF) 2x Rubycon (10,000h @105°C, YXM) 1x Rubycon (3-6,000h @105°C, YXG) Polymer: 6x Apaq, 9x Chemic-Con, 2x Elite, 8x |

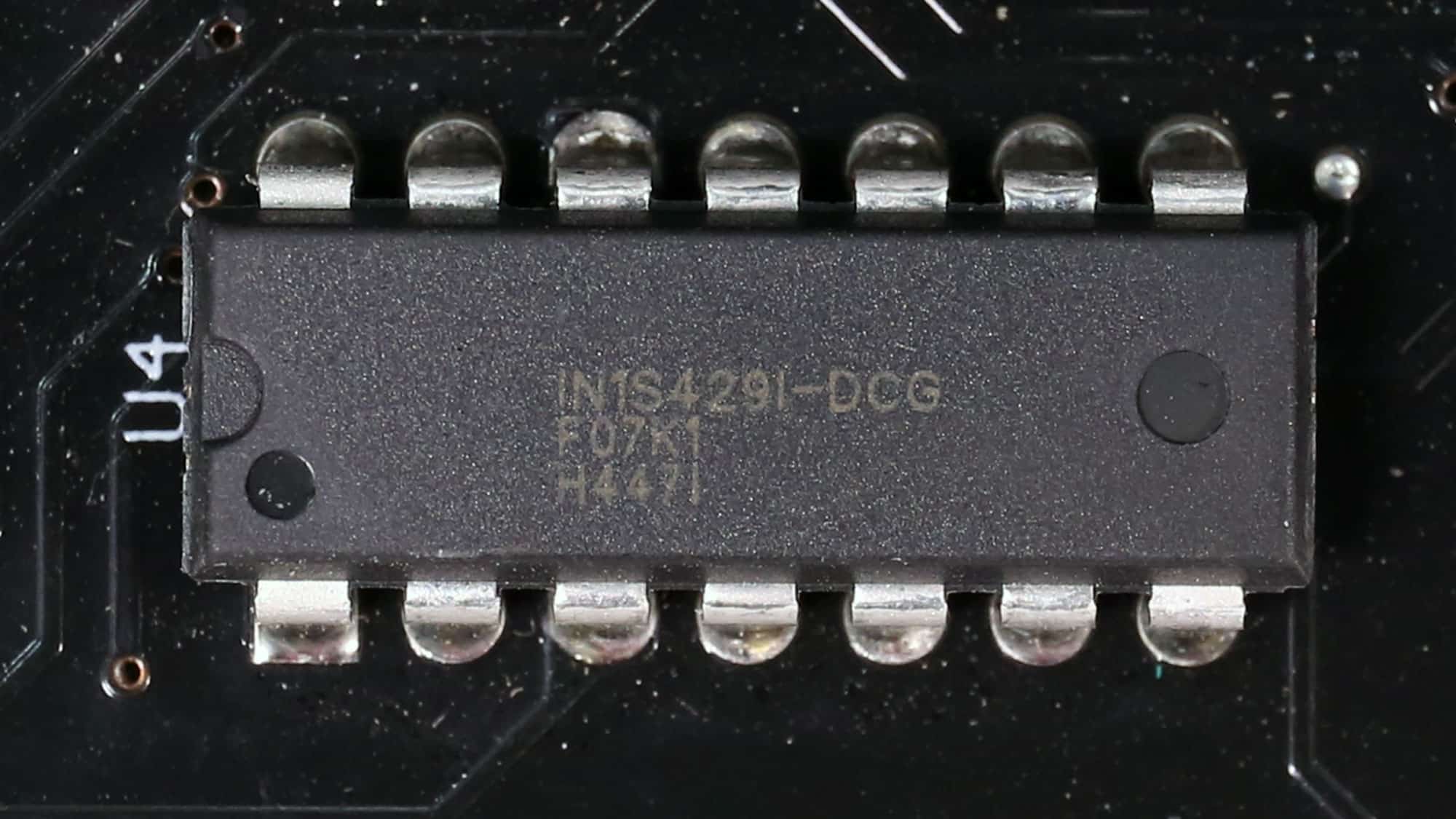

| Supervisor IC | IN1S429I-DCG |

| Fan Controller | STMicroelectronics ST69345 |

| Fan Model | CWT12025H12F-9 (120mm, 12V, 0.24A, Fluid Dynamic Bearing Fan) |

| 5VSB | |

| Rectifier |

ES3JBF (600V, 3A)

|

| Standby PWM Controller |

Power Integrations TNY290PG

|

The OEM is Channel Well Technology (CWT), and the PSU also uses CWT’s in-house-made fan. CWT didn’t want to rely so much on other fan manufacturers for its PSUs, so it devoted time, money, and resources to building its own fans. You can find more about CWT’s fan performance in the Cybenetics respective database.

The small PCB has an interesting layout, with compact heatsinks on the secondary side and larger ones on the primary side. The lack of large heatsinks allows for a less cramped PCB, but on the other hand, it doesn’t help in driving the fan’s speed lower, especially under harsh operating conditions. Moreover, I don’t want to see electrolytic caps close to heatsinks, because they get hotter and even a slight increase in a cap’s operating temperature, notably affects its lifetime. On the primary side, we find an APFC converter, a full-bridge topology, and an LLC resonant converter for the primary and the 12V FETs. On the secondary side, a synchronous rectification scheme and a pair of VRMs are used for the generation of the minor rails. Moreover, the fan utilizes a dedicated fan controller, which better manages the speed profile.

The transient filtering stage contains all the necessary components to block both incoming and outgoing EMI emissions. Typically, it starts at the AC receptacle and continues on the main PCB. CWT also equipped the transient filter with a discharge IC to bleed the X caps without affecting efficiency.

There is an MOV to protect from voltage surges and an NTC thermistor. Moreover, a bypass relay supports the NTC thermistor.

The two GBU1006 parallel bridge rectifiers can handle up to 20A together.

The APFC converter uses two WayOn WML53N60C4 FETs and one CRMicro CRX10D065G2 boost diode. Elite manufactures the bulk capacitors. Their combined capacity is 940 μF, and they are rated for 2,000 hours at 105 °C. Their voltage rating is high enough at 420V. Remember the APFC’s DC bus voltage is approximately 380V DC.

The APFC controller is a Champion CM6500UNX.

The four WayOn WML26N65F2 primary switching FETs are installed in a full-bridge topology, and an LLC resonant converter is used to achieve higher efficiency.

The LLC resonant controller is a Champion CM6901X.

The PSU’s main transformer. One of its main functions is to isolate the primary and secondary sides electrically.

Eight IPS FTG014N04SA FETs regulate the 12V rail. They are installed on the business (top) side of the main PCB.

Two DC-DC converters generate the minor rails. They use four UBIQ QM3054M6 FETs. I couldn’t identify the PWM controller.

Rubycon, Chemi-Con, and Nichicon provide the electrolytic caps. The polymer caps are by Apaq, Elite, Chemi-Con, and another brand, which I couldn’t identify.

You can find more information about capacitor performance and other specs below:

The standby PWM controller is a Power Integrations TNY290PG. The primary rectifier of the standby rail is an ES3JBF.

Several polymer caps at the face of the modular panel form an extra ripple-filtering layer.

The soldering quality is mediocre, and in some areas, it’s pretty poor. Since CWT has quality production lines, I likely received a pre-production sample that included several hand-made soldering jobs. These might look bad, but they won’t affect performance.

The supervisor IC is an IN1S429I-DCG.

The cooling fan is a CWT12025H12F-9, utilizing a fluid dynamic bearing. The dedicated controller enables easy adjustment of the fan’s speed profile.