Part Analysis

| General Data | |

| Manufacturer (OEM) | High Power |

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV, 1x Discharger IC HF81 |

| Inrush Protection | 1x NTC Thermistor & Relay |

| Bridge Rectifier(s) |

1x

|

| APFC MOSFETs |

1x Infineon IPZ60R040C7 (650V, 32A @ 100°C, Rds(on): 0.040Ohm)

|

| APFC Boost Diode |

1x Macrocore HX1D10065A (650V, 10A @ 150°C)

|

| Bulk Cap(s) |

1x Nippon Chemi-Con (420V, 560uF, 2,000h @ 105°C, KHE)

|

| Main Switchers |

2x Infineon IPP60R070CFD7 (650V, 20A @ 100°C, Rds(on): 0.07Ohm)

|

| APFC Controller |

1x

|

| Resonant Controller |

Champion CU6901VAC

|

| Topology |

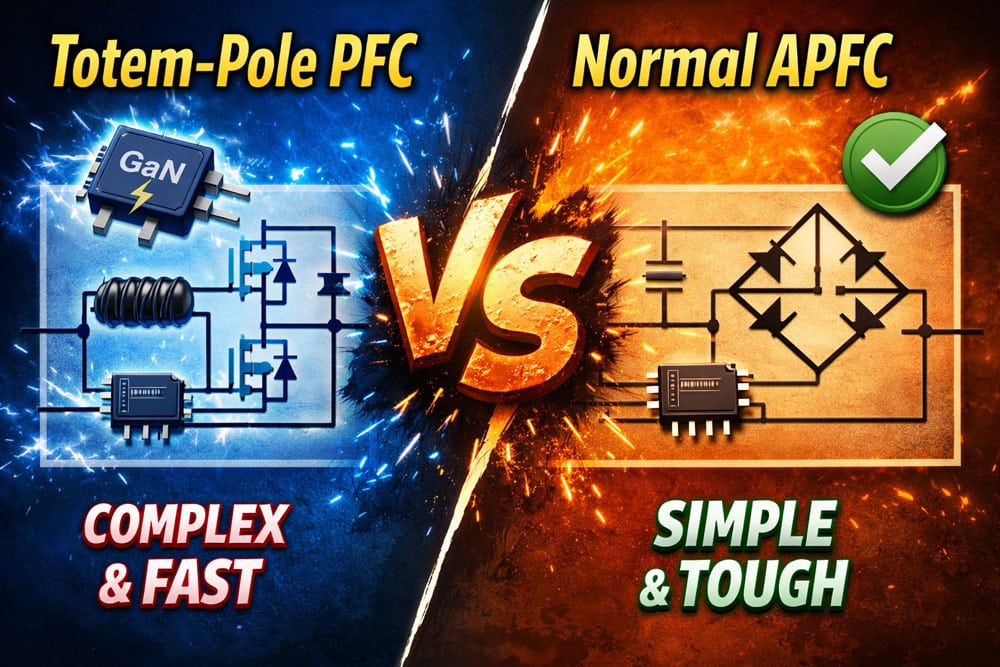

Primary side: APFC, Half-Bridge & LLC Resonant converter

Secondary side: [12V] Synchronous Rectification & [Minor Rails] DC-DC converters |

| Secondary Side | |

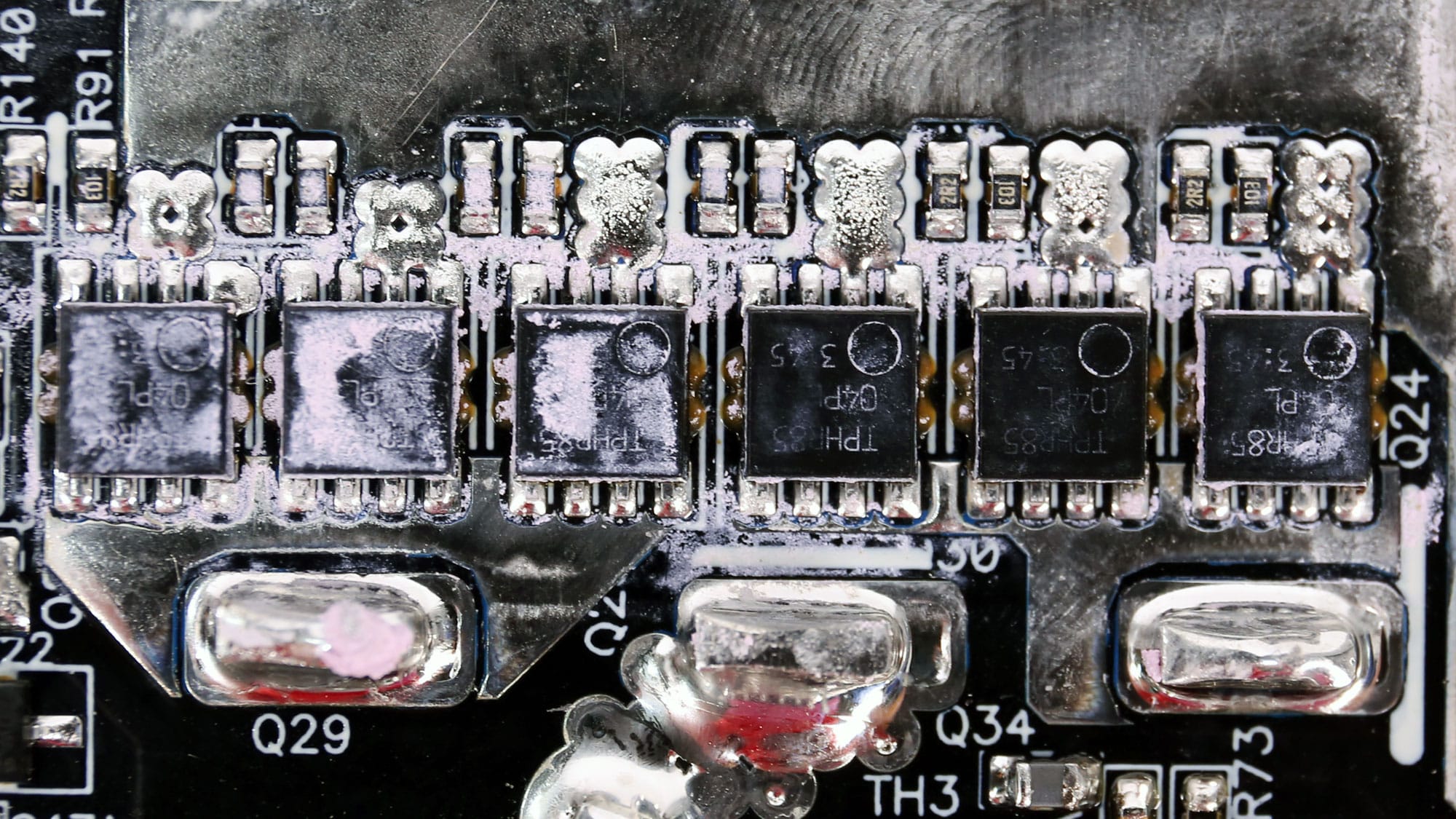

| +12V MOSFETs | 6x Toshiba TPHR8504PL (40V, 150A @ 25°C, Rds(on): 1.4mOhm) |

| 5V & 3.3V | DC-DC Converters: 6x Infineon BSC0906NS (30V, 40A @ 100°C, Rds(on): 4.5mOhm) PWM Controller(s): uPI Semi uP3861P |

| Filtering Capacitors | Electrolytic: 4x Rubycon (6-10,000h @105°C, ZLH) 1x Rubycon (3-6,000h @105°C, YXG) Polymer: 21x FPCAP |

| Supervisor IC | 1x |

| MCU/Fan Controller | STCMicro STC115W401AS |

| Fan Model | Globe Fan S0921512HHB (92mm, 12V, 0.5A, Fluid Dynamic Bearing Fan) |

| 5VSB | |

| Rectifier(s) |

1x Infineon IPD70R1K4P7S (700V, 2.5A @ 100°C, Rds(on): 1.4mOhm) &

1x Vishay RS1D (140V, 30A @ 150°C) & 1x Dongke DK5V45R15V (45V, 15mOhm) |

| Standby PWM Controller |

Si-Trend SI8016HSP8

|

The OEM, High Power, has a long history in the small form factor market. The PCB is overloaded with parts, as it must include the necessary components to handle 1000W of power. Furthermore, the large primary heatsink occupies a significant portion of the PCB’s already limited space. Everything is cramped in a high-power compact PSU, so don’t expect its fan to run at low speeds to keep the internal temperatures in control.

On the primary side, we find the typical staff: an APFC converter, a half-bridge topology, and an LLC resonant converter for the primary and the 12V FETs. On the secondary side, a synchronous rectification scheme and a pair of VRMs are used for the generation of the minor rails. Moreover, the fan utilizes a dedicated can controller, which enables it to spin at very low speeds, thereby keeping the noise output low.

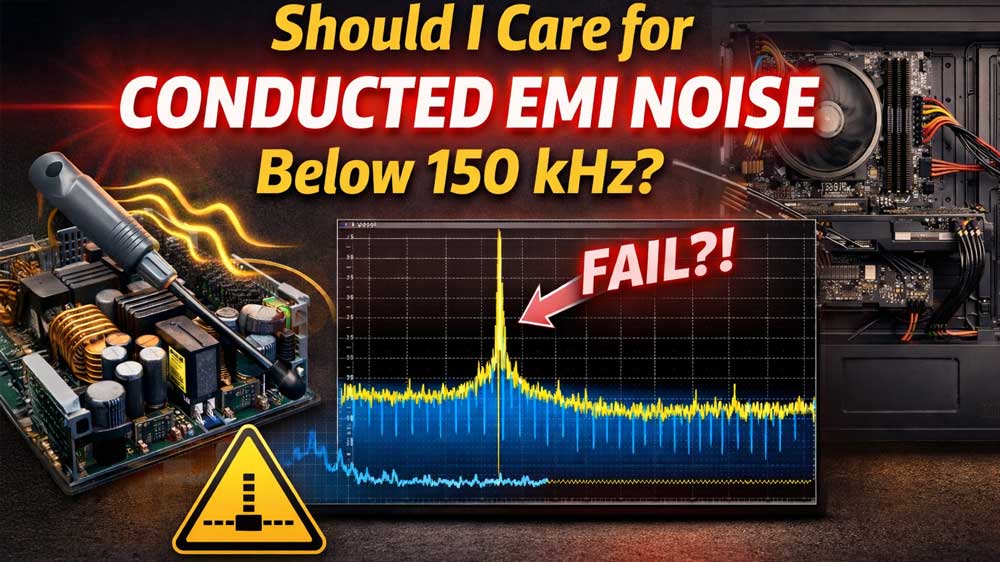

The transient filtering stage contains all the necessary components to block both incoming and outgoing EMI emissions. Typically, it starts at the AC receptacle and continues on the main PCB. There is also a discharge IC providing a slight efficiency boost.

There is an MOV to protect from voltage surges and an NTC thermistor. Moreover, a bypass relay supports the NTC thermistor.

One bridge rectifier handles the power input needs. I couldn’t recognize it with some serious desoldering, which could damage the PSU.

The APFC converter uses a single Infineon IPZ60R040C7 FET and one Macrocore HX1D10065A boost diode. Nippon Chemi-Con manufactures the bulk capacitor, which has a low capacity for a 1000W PSU. The two Infineon IPP60R070CFD7 primary switching FETs are installed in a half-bridge topology, and an LLC resonant converter is used to achieve higher efficiency.

The LLC resonant controller is a Champion CU6901VAC.

The PSU’s main transformer. One of its main functions is to isolate the primary and secondary sides electrically.

Six Toshiba TPHR8504PL FETs regulate the 12V rail. They are installed on the solder (rear) side of the main PCB.

Two DC-DC converters generate the minor rails. They use six Infineon BSC0906NS FETs. The PWM controller is a uPI Semi uP3861P.

Rubycon makes all electrolytic caps. The polymer caps are by FPCAP.

You can find more information about capacitor performance and other specs below:

The standby PWM controller is a Si-Trend SI8016HSP8.

Several polymer caps at the face of the modular panel form an extra ripple-filtering layer. There are also three electrolytic caps on this side.

The soldering quality is generally good.

The cooling fan is a Globe Fan S0921512HHB, utilizing a fluid dynamic bearing. The dedicated controller enables easy adjustment of the fan’s speed profile, allowing it to spin at low speeds.

I would like to know the noise output of the electric circuit in the PSU. My SF1000 outputs a 14953hz noise, it gives me headache. I would like to get something that don’t have this noise.

On 220V

this is not possible because each PSU once connected to a specific system affects it, so frequency analysis on a single PSU alone won’t mean anything regarding coil whine.