Part Analysis

| General Data | |

| Manufacturer (OEM) | Andyson |

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | NTC Thermistor SCK205R0 (5 Ohm @ 25°C) & Relay |

| Bridge Rectifier(s) |

2x GBU1006 (420V, 15A @ 100°C)

|

| APFC MOSFETs |

2x Wayon WML28N65F2 (650V, 13A @ 100°C, Rds(on): 0.19Ohm)

|

| APFC Boost Diode |

1x WeEn BYC10-600P (600V, 20A @ 127°C)

|

| Bulk Cap(s) |

2x Nippon Chemicon (420V, 330uF each or 660uf combined, 2000h @ 105°C, KMR)

|

| Main Switchers |

4x Chongqing Pingwei 18N50MF (500V, 18A @ 25°C, Rds(on): 0.3Ohm)

|

| APFC Controller |

Champion CM6500UNX

|

| Resonant Controller | Champion CU6901VPA |

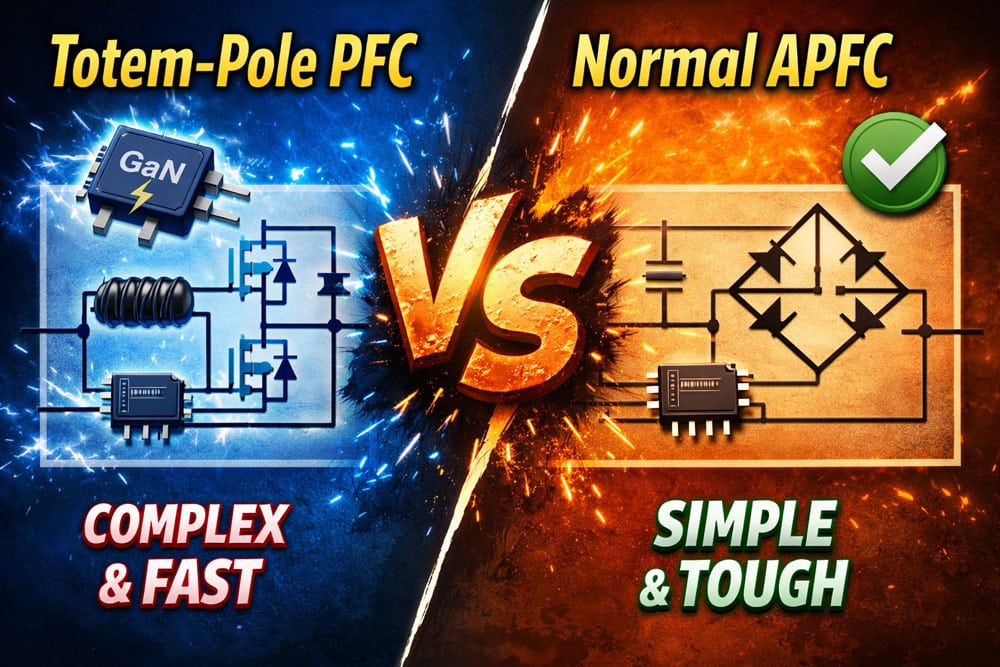

| Topology |

Primary side: APFC, Full-Bridge & LLC converter

Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 6x Allpower APG013N04G-AU (40V, 100A @ 100°C, Rds(on): 1.3mOhm) |

| 5V & 3.3V | DC-DC Converters: 6x Nexperia PSMN4R0-30YLD (30V, 95A @ 25°C, Rds(on): 4mOhm) PWM Controller(s): ANPEC APW7159C |

| Filtering Capacitors | Electrolytic: 6x Nippon Chemi-Con (2-5,000 @ 105°C, KZE), 4x Rubycon (6-10000 @ 105°C, ZLH), 1x Nichicon (4-10,000 @ 105°C, HE)Polymer: 24x Polycap, 5x FPCAP, 1x Nippon Chemi-Con LE |

| Supervisor IC | Weltrend WT7527RA (OCP, OTP, OVP, UVP, SCP, PG) |

| MicroController / Fan Controller | Weltrend WT51F104 |

| Fan Model | Hong Hua HA1225M12F-Z (120mm, 12V, 0.45A, Fluid Dynamic Bearing) |

| 5VSB Circuit | |

| Rectifier |

PJ335M

|

| Standby PWM Controller | Excelliance MOS EM8569C |

Andyson provides the platform, which uses a contemporary design. The primary side has a full-bridge topology and an LLC resonant converter for reduced energy losses. On the secondary side, six Allpower FETs regulate the 12V rail, which feeds a pair of DC-DC converters that generate the minor rails. The build quality is good, and quality caps are on both the primary and secondary sides. On the contrary, the FETs used on the APFC converter, the full-bridge topology, and for the regulation of the 12V rails are from less-known manufacturers. Lastly, the soldering quality is satisfactory, as was the case in the 1000W model (but not in the 1200W unit).

Hong Hua provides the cooling fan. This manufacturer offers good and reliable products, so the PSU’s fan will last long if you don’t stress it under high operating temperatures (above 40 degrees Celsius). Because of the PSU’s compact dimensions, a 120mm fan was used instead of a larger one, which would offer the same airflow at lower speeds, reducing the average noise output.

Ripple suppression is IMHO even remarkable, not only good. I compare to the SilverStone DA750R Gold review on Tomshardware, which is a very similar PSU, probably build on the identical Andyson platform (P32).

Just compare the part analysis of the Silverstone and the Sharkoon, the inner build is very similar with some light benefits for the P20 (like the better fan):

https://cdn.mos.cms.futurecdn.net/CWhpy3Gr4RFLT4ycbF7Xi7-970-80.jpg

Heatsinks and layout are identical. Ignore what the review says (“Internally, the DA750R utilizes a platform from HKC and incorporates Ltec, Teapo and Polycap capacitors”) – this is not true if you check the pictures and they admit the error in the comments.

Coming back to ripple supression, the Tomshardware-Review of the DA750R by quote: “Ripple suppression is outstanding for a unit of this class, with maximum ripple levels of 28 mV on the 12V rail, 18 mV on the 5V rail, and 18 mV on the 3.3V rail, well within the industry standard limits for this tier.” If this is truly outstanding, then the PA20 750w should be even better, as it has even lower mVs. Whats better than outstanding? Certainly not the word “good”.

Anyone knows the OEM of the P10-series?