Part Analysis

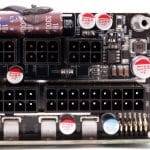

| General Data | |

| Manufacturer (OEM) | CWT |

| Platform | CTE |

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | 1x NTC Thermistor SCK207R0 (7 Ohm) & Relay |

| Bridge Rectifier(s) |

2x GBJ1506 (600V, 15A @ 100°C)

|

| APFC MOSFETs |

2x Vishay SiHA105N60EF (600V, 8A @ 100°C, Rds(on): 0.102Ohm)

|

| APFC Boost Diode |

1x Vishay VS-3C10ET07T-M3 (650V, 10A @ 140°C)

|

| Bulk Cap(s) |

1x Rubycon (420V, 820uF, 2,000h @ 105°C, MXE)

|

| Main Switchers |

2x STMicroelectronics STF33N60DM2 (650V, 15.5A @ 100°C, Rds(on): 0.130Ohm)

|

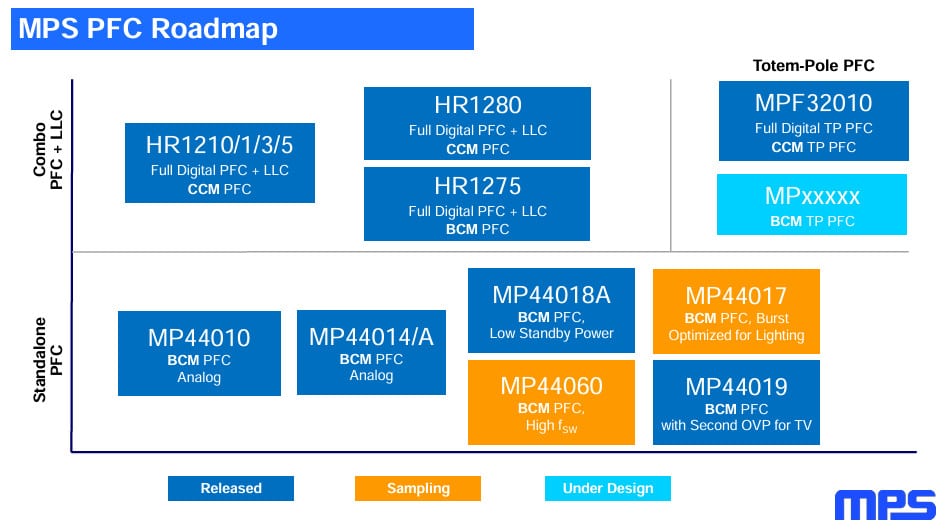

| PFC / PWM Combo Controller | MPS HR1280 |

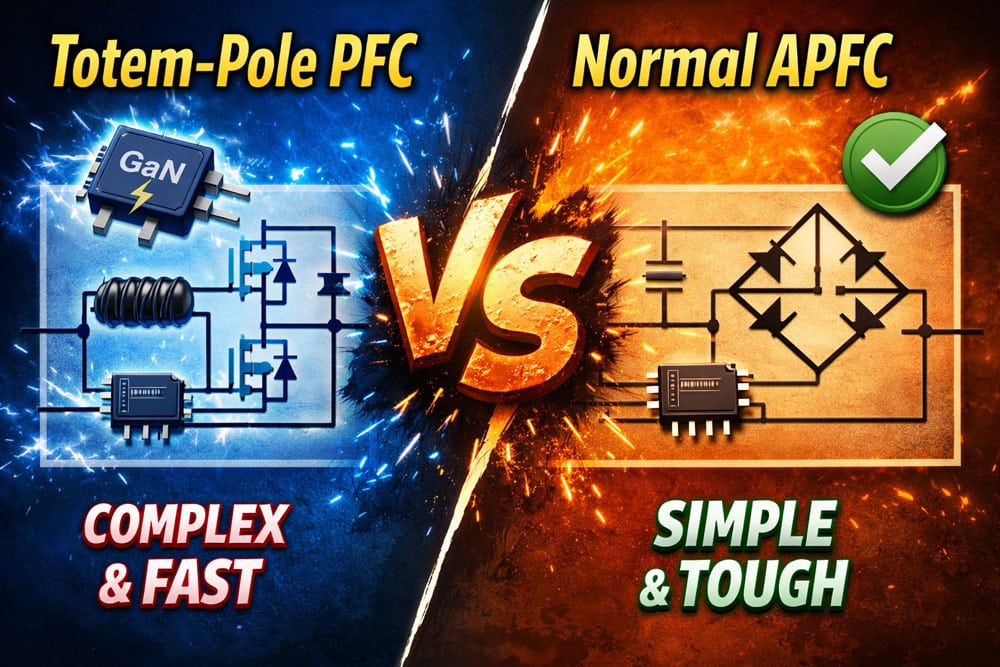

| Topology | Primary side: Semi-Digital, APFC, Half-Bridge & LLC Resonant Converter Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 6x On Semiconductor NTMFS5C430N (40V, 131A @ 100°C, Rds(on): 1.7mOhm) |

| 5V & 3.3V | DC-DC Converters: 2x UBIQ QM3054M6 (30V, 61A @ 100°C, Rds(on): 4.8mOhm) & 2x UBIQ QN3107M6N (30V, 70A @ 100°C, Rds(on): 2.6mOhm) |

| Filtering Capacitors | Electrolytic: 2x Nippon Chemi-Con (@ 105°C, W) 2x Nippon Chemi-Con (2-5,000h @ 105°C, KZE), 2x Rubycon (3-6,000h @ 105°C, YXS) 1x Rubycon (6-10,000h @ 105°C, ZLH) Polymer: 2x Nippon Chemi-Con, 23x FPCAP |

| Supervisor IC | – |

| Fan Controller | Nuvoton MS51FB9AE |

| Fan Model | ZIC ZFF132512H BAX3 (135mm, 12V, 0.45A, Fluid Dynamic Bearing Fan) |

| 5VSB Circuit | |

| Rectifier |

1x Dongke Semiconductor DK5V45R10S (45V, 10A)

|

| Standby PWM Controller | On Bright OB2365T |

The compact PCB has large enough heatsinks not to stress the active cooling, since the platform’s efficiency is Gold and not Platinum or Titanium, so thermal losses will be significant at high loads. This is the CTE platform by CWT, which uses a digital combo PFC/LLC resonant controller provided by MPS. This means that the design is semi-digital since a digital controller controls the primary side and a part of the secondary. We would have a fully digital platform if the VRMs generating the minor rails and the 5VSB circuit were also digitally controlled. But guess what? This would increase the cost, and most likely, no one would want to pay above 200 dollars for a 1000W Gold PSU.

The 12V FETs are installed on the main PCB’s top side, and some heatsinks on top cool them down. The 12V FETs are close to the main transformer to minimize energy losses, and the VRMs generating the minor rails are nearby for the same reason. CWT used high-quality parts, including top-notch FETs and capacitors, to increase the platform’s reliability and performance. In the sample I got, the soldering quality was mediocre to ba,d though, in some parts. This is typical for pre-production samples, where many soldering jobs are hand-made. I will ask MSI to send me the final production products so I can check on the soldering quality!

The cooling fan is made by ZETA, which looks to be a worthy opponent for Hong Hua, which has dominated the market for the last few years. It uses a fluid dynamic bearing for increased reliability and lower noise output. I noticed some bearing noise at low speeds (200-400 RPM), and the fan started from 400 RPM in my tests. It would be ideal if MSI started the fan from 500 RPM, where the bearing noise is minimized. To give you an idea, at 400 RPM, the fan’s noise is 12.1 dBA at a 1-meter distance, while at 500 RPM, the noise is at 10.8 dBA at the same distance. This most likely will pass unnoticed by most users.

Considering getting the A1250GS version of this as I have a MSI 5090 Vanguard coming in soon and currently only have a EVGA 1000 GT for my 13900K/5090 build. Do you think the 1250 version should be similar to this one? I was looking to get an ATX 3.1 PSU and mainly wanted to go with MSI on the off chance anything happens with the card, they then can’t blame the PSU.

1250W is by the same OEM CWT. One problem we had at 115V is that the APFC confused our power analyzers, dropping low PF

Hello, Aris ! I’ve been looking at multiple benchmarks and reviews on your page and on the cybernetic’s site and idk that psu to choose for a 5070 level of build, the super flower 850w leadex vii gx, the msi a850g, or the corsair rmx 850w atx 3.1, price wise the first 2 are basically the same price and the corsair one is 25$ more expensive

I would probably go for the Corsair unit. 25 dollars more is nothing for a PC part that you will keep for many years.

Are super flower units such as leadex vii xg and pro variants not as good as people say they are ?

they are pretty good. Who says the opposite?

Thanks for your suggestion ,but I’ll probably get the xg psu because it’ll allow for a longer gpu in my 20l case

Hi, Aris! I scrolled down Enermax’s website, and came up with Enermax Revolution III. It is said to be ATX 3.1, and i’m pretty sure it’s a replacement for Revolution DF judging from its price

Would you be consider to review this unit? Thanks

if Enermax sends it over, I could take a look 🙂

hello Aris did Gigabyte sends you some of their new AI PSU ?

GBT doesn’t even talk to me, for many years now after I exposed its failure PSUs.