Part Analysis

| General Data | |

| Manufacturer (OEM) | Great Wall |

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | 1x NTC Thermistor SCK205R0 (5 ohm) & Relay |

| Bridge Rectifier(s) |

2x GBU25KH (800V, 25A @ 25°C)

|

| APFC MOSFETs |

2x Rohm Semiconductor R6055VNZ4 (600V, 55A @ 55°C, Rds(on): 0.080Ohm)

|

| APFC Boost Diode |

1x WeEn Semiconductor WNSC6D06650 (650V, 6A @ 156°C)

|

| Bulk Cap(s) | |

| Main Switchers |

2x STMicroelectronics STW48N60DM2 (600V, 25A @ 100°C, Rds(on): 0.079Ohm)

|

| APFC Controller | |

| Resonant Controller |

Champion CM6901T6X

|

| IC Driver |

1x Novosense NSi6602

|

| Topology |

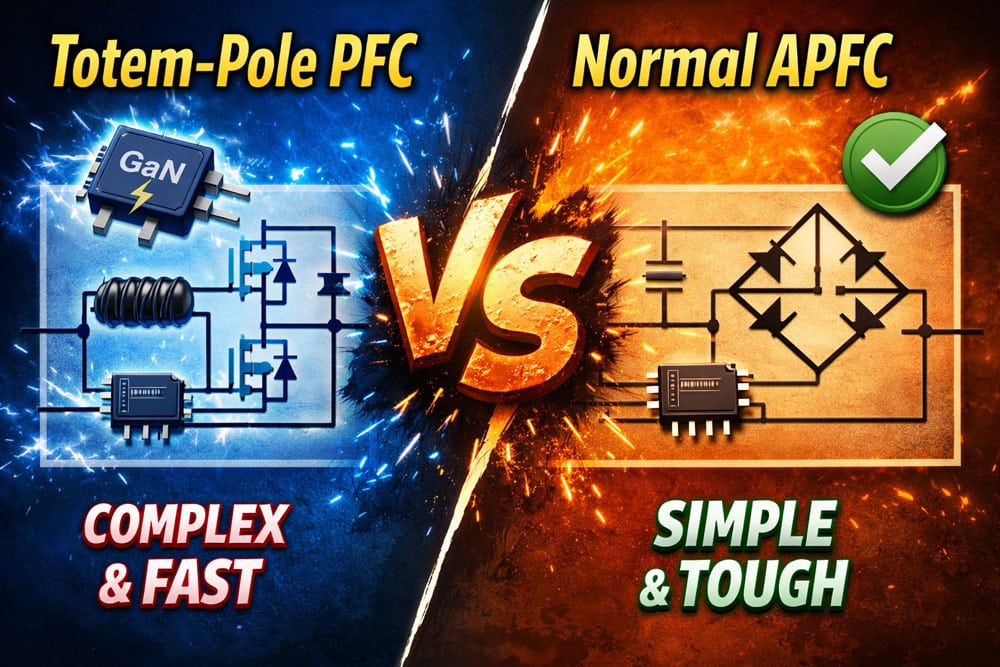

Primary side: APFC, Half-Bridge & LLC Resonant Converter

Secondary side: [12V] Synchronous Rectification & [Minor Rails] DC-DC converters |

| Secondary Side | |

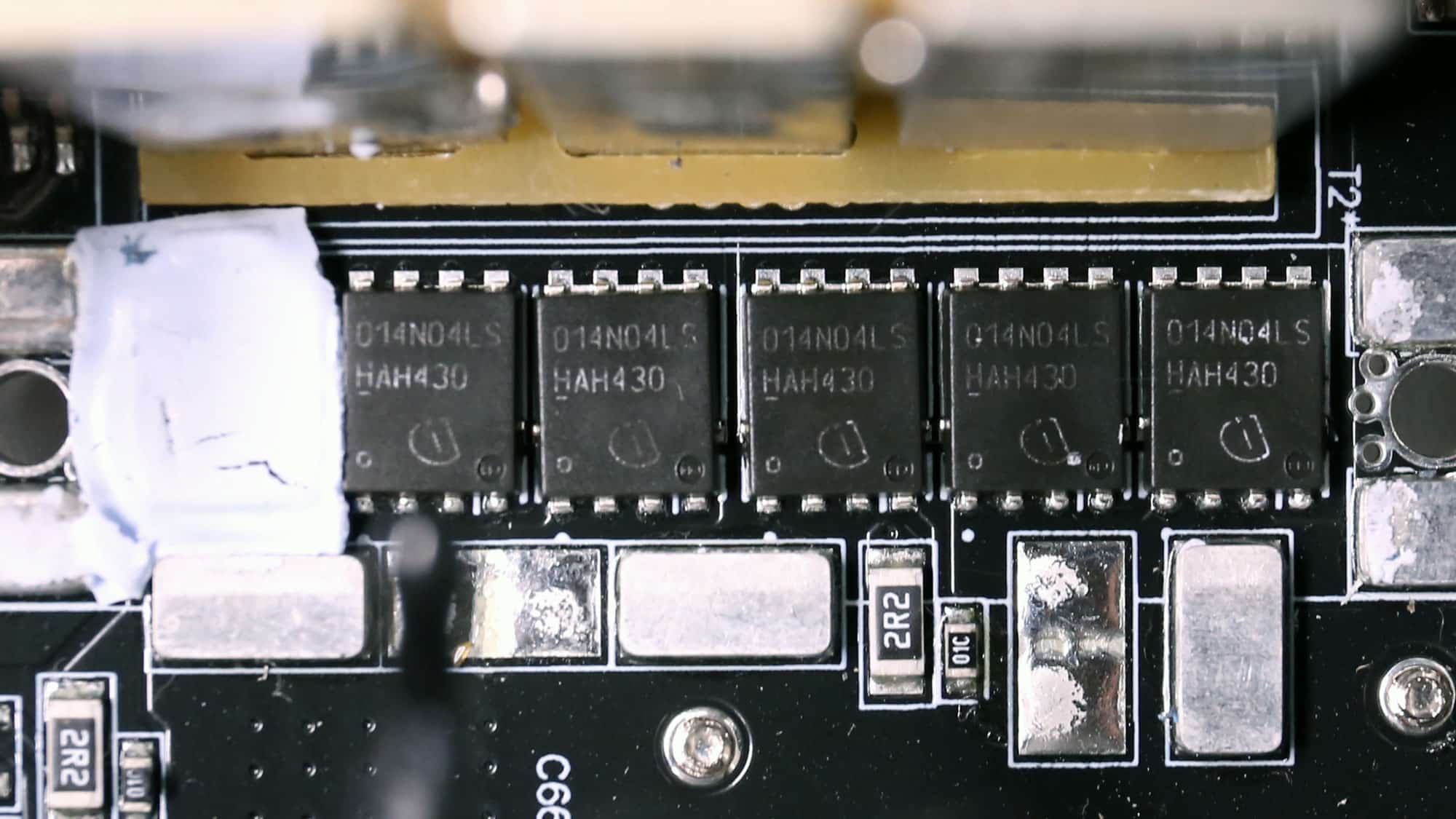

| +12V MOSFETs | 6x Infineon BSC014N04LS (40V, 145A @ 100°C, Rds(on): 1.4mOhm) |

| 5V & 3.3V | DC-DC Converters: 4x DMTH3004LK3 (30V, 75A @ 70°C, Rds(on): 4mOhm) PWM Controller(s): Anpec APW7159C |

| Filtering Capacitors | Electrolytic: 12x Nippon Chemi-Con (2-5,000h @105°C, KZE) 2x Rubycon (2-10,000 @ 105°C, YXF) 2x Rubycon (4-10,000h @105°C, YXJ) 1x Rubycon (3-6,000h @105°C, YXG) 1x Rubycon (2-10,000 @ 105°C, ZLH) Polymer: 21x FPCAP, 11x Nippon Chemi-Con |

| Supervisor IC | 1NIS4291-SCG |

| Fan Model | Hong Hua HA1425M12F-Z (140mm, 12V, 0.36A , Fluid Dynamic Bearing Fan) |

| 5VSB | |

| Rectifier |

STMicroelectronics STPS1045B (45V, 10A)

|

| Standby PWM Controller |

Power Integrations TNY278PN

|

The OEM is Great Wall and the platform uses a contemporary design. I like the fact that the electrolytic capacitors on the secondary side are on the open, so airflow to them is unobstructed. The 12V FETs are soldered to the main PCB and positioned close to the main transformer to minimize energy losses. In contrast, the VRMs handling the minor rails are located on a daughter board situated on one of the PSU’s sides. The heatsinks on the primary side are large enough to allow for lower fan speeds; however, this is not the case for the secondary side. It would be ideal if the MCU digitally controlled the fan through PWM, but GW dropped that option since it would increase production costs.

The transient filtering stage contains all the necessary components to block both incoming and outgoing EMI emissions. Typically, it starts at the AC receptacle and continues on the main PCB.

There is an MOV to protect from voltage surges and an NTC thermistor with a resistance of 5 ohms. Moreover, a bypass relay supports the NTC thermistor.

The two GBU25KH parallel bridge rectifiers can handle up to 50A together.

The APFC converter uses two Rohm Semiconductor R6055VNZ4 FETs and one WeEn Semiconductor WNSC6D06650 diode. Rubycon manufactures the bulk capacitors. Their combined capacity is 1150 μF, and both are rated for 3,000 hours at 105 °C. Voltage ratings are 420V and 450V, which are far enough from the APFC’s DC bus voltage (approximately 380-400V DC).

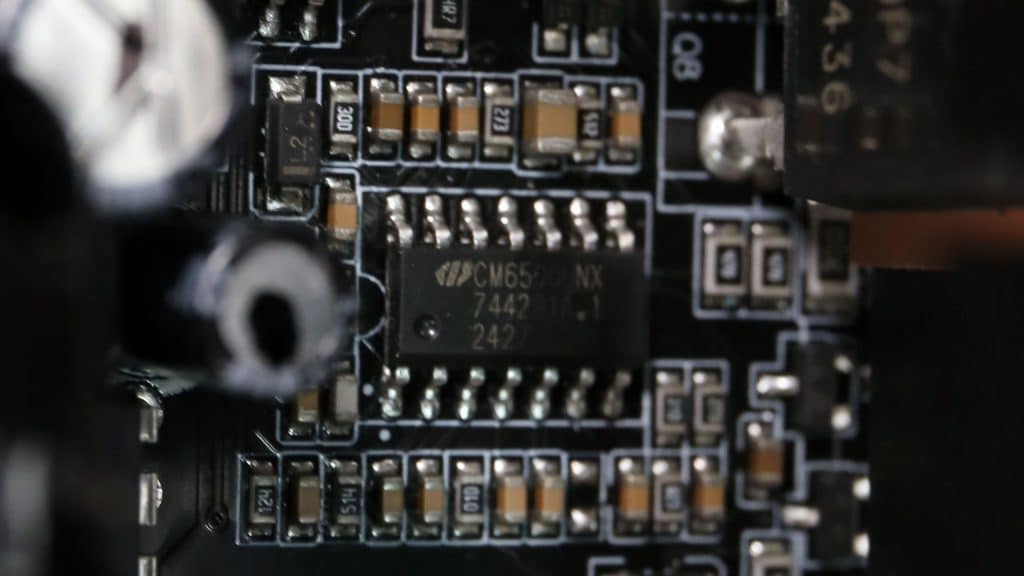

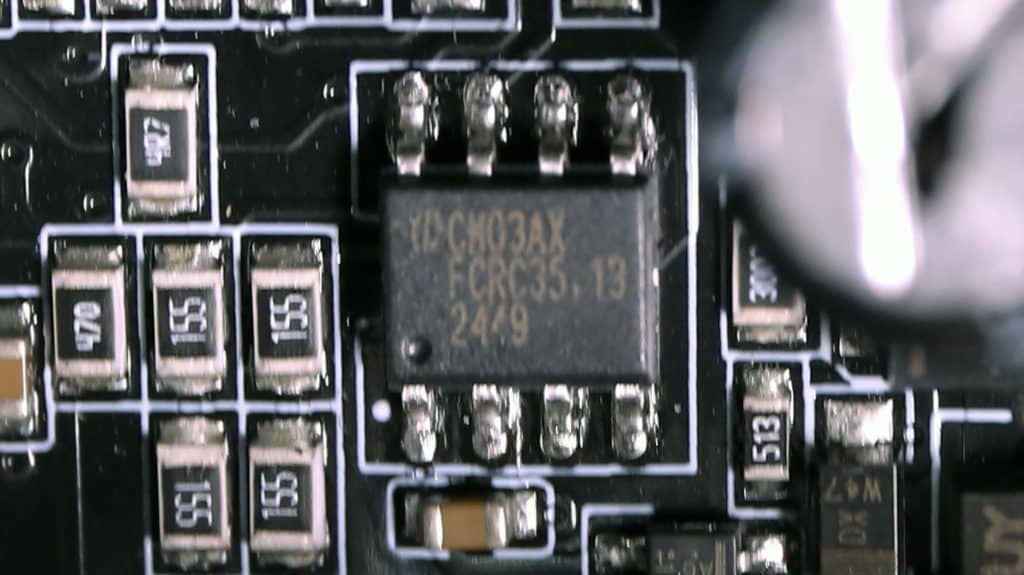

The APFC controller is a Champion CM6500UNX. A CM03AX supports it for reduced vampire power.

The two STMicroelectronics STW48N60DM2 primary switching FETs are installed in a half-bridge topology, and an LLC resonant converter is utilized for enhanced efficiency.

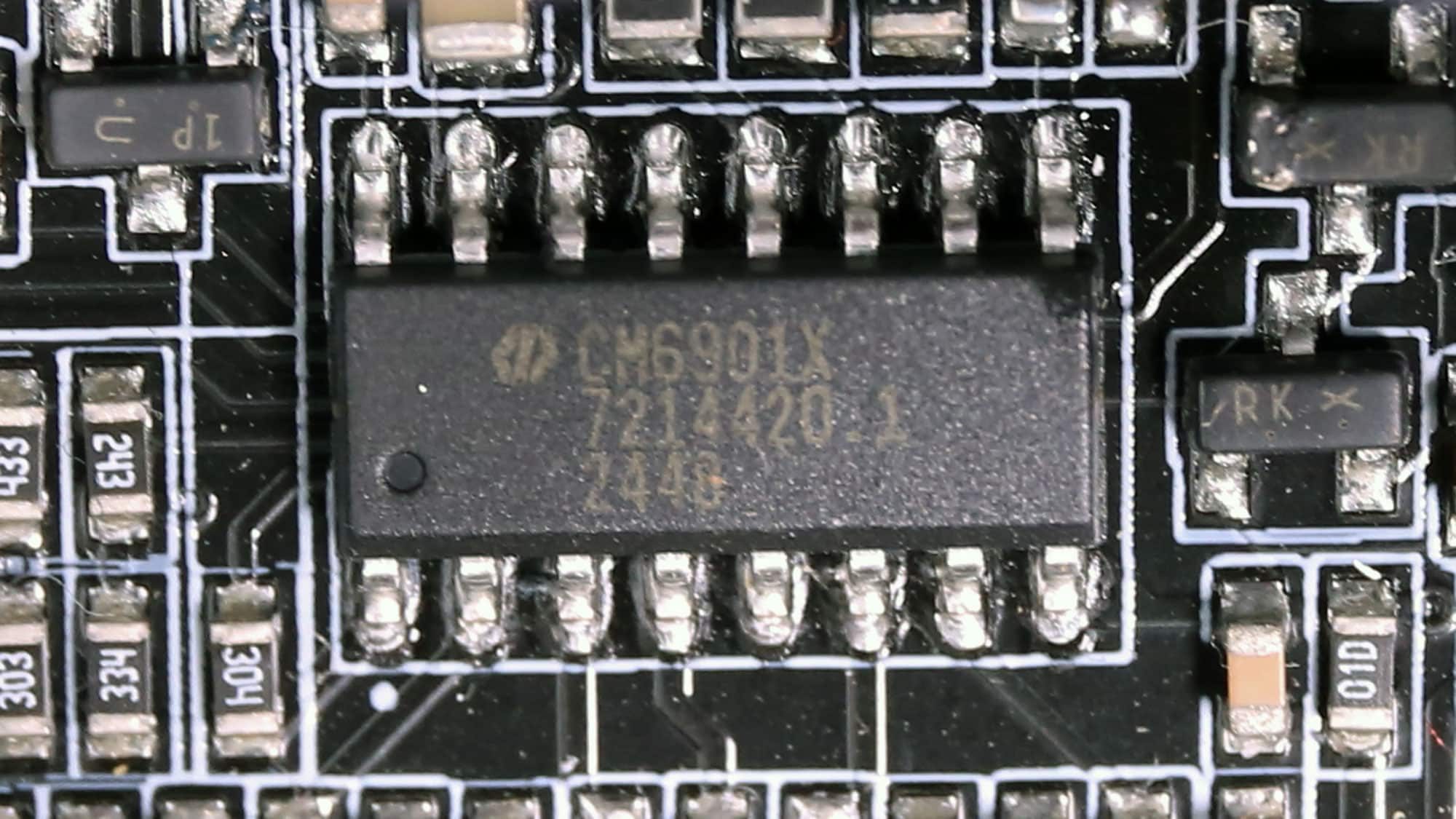

The LLC resonant controller is a Champion CM6901X.

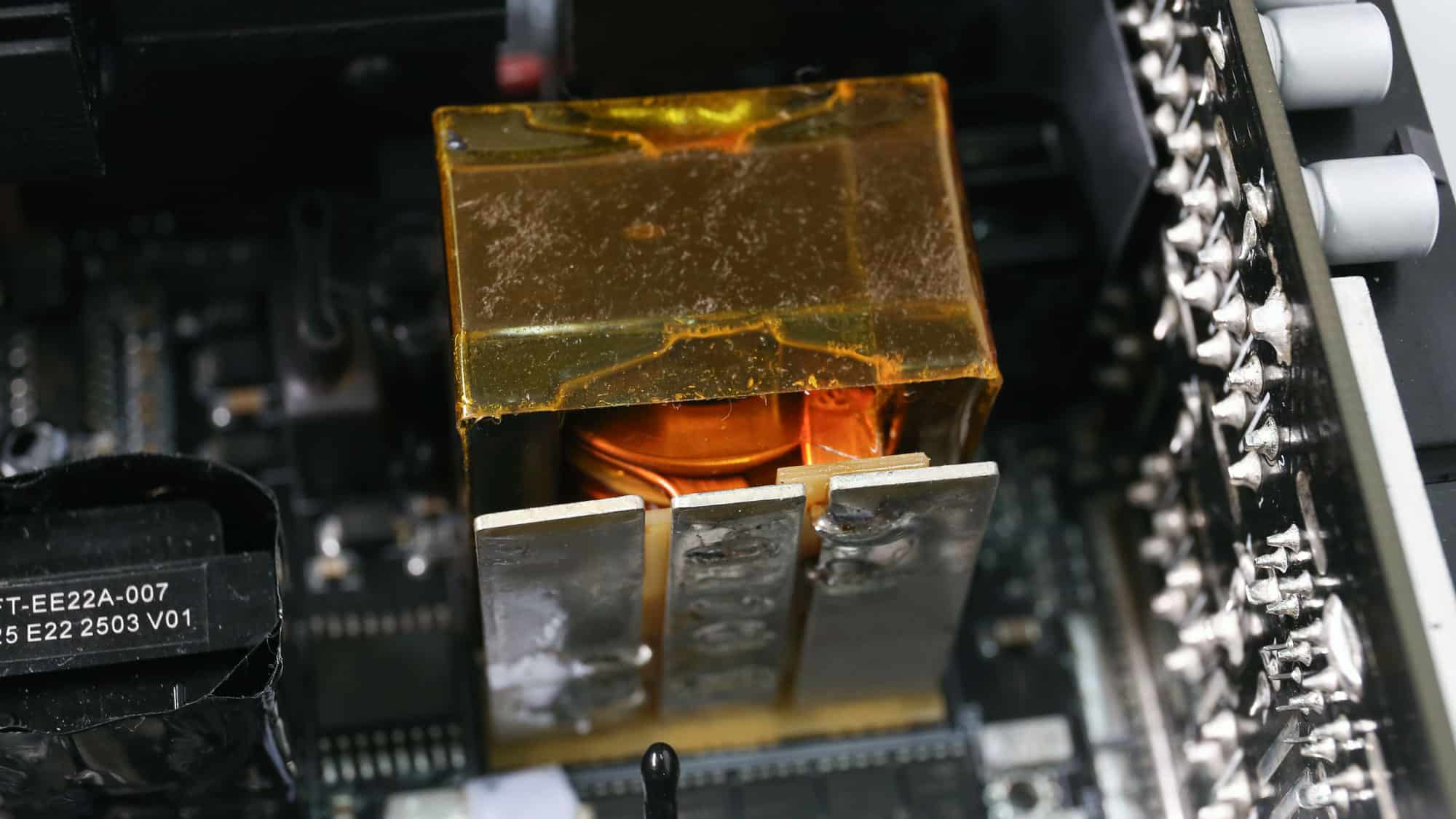

The PSU’s main transformer. One of its main functions is to isolate the primary and secondary sides electrically.

Six Infineon BSC014N04LS FETs regulate the 12V rail. They are installed on the business (top) side of the main PCB.

Two DC-DC converters generate the minor rails. They use four DMTH3004LK3 FETs. The PWM controller is an Anpec APW7159C.

Chemi-Con and Rubycon provide the electrolytic capacitors. FPCAP and Chemi-Con make the polymer capacitors.

You can find more information about capacitor performance and other specs below:

The standby PWM controller is a Power Integrations TNY278PN, and the secondary side rectifier is a STMicroelectronics STPS1045B.

Many polymer caps at the face of the modular panel form an extra ripple-filtering layer.

The soldering quality is satisfactory.

The cooling fan is a Hong Hua HA1425M12F-Z, utilizing a fluid dynamic bearing.