Part Analysis

| General Data | |

| Manufacturer (OEM) | CWT |

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 6x Y caps, 2x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | 1x NTC Thermistor SCK-037 (3 Ohm @25°C) & Relay |

| Bridge Rectifier(s) |

2x GBJ1506 (600V, 15A @ 100°C)

|

| APFC MOSFETs |

2x Infineon IPA60R125P6 (650V, 19A @ 100°C, Rds(on): 0.125Ohm) &

1x Sync Power SPN5003 FET (for reduced no-load consumption) |

| APFC Boost Diode |

1x Onsemi FFSP0865A (650V, 8A @ 155°C)

|

| Bulk Cap(s) |

2x Nippon Chemi-Con (400V, 470uFeach or 940both, 2000h @ 105°C, KMW)

|

| Main Switchers |

2x Infineon IPA60R190P6 (650V, 12.7A @ 100°C, Rds(on): 0.190Ohm)

|

| APFC Controller |

Champion CM6500UNX

|

| Resonant Controller |

Champion CU6901VACNH

|

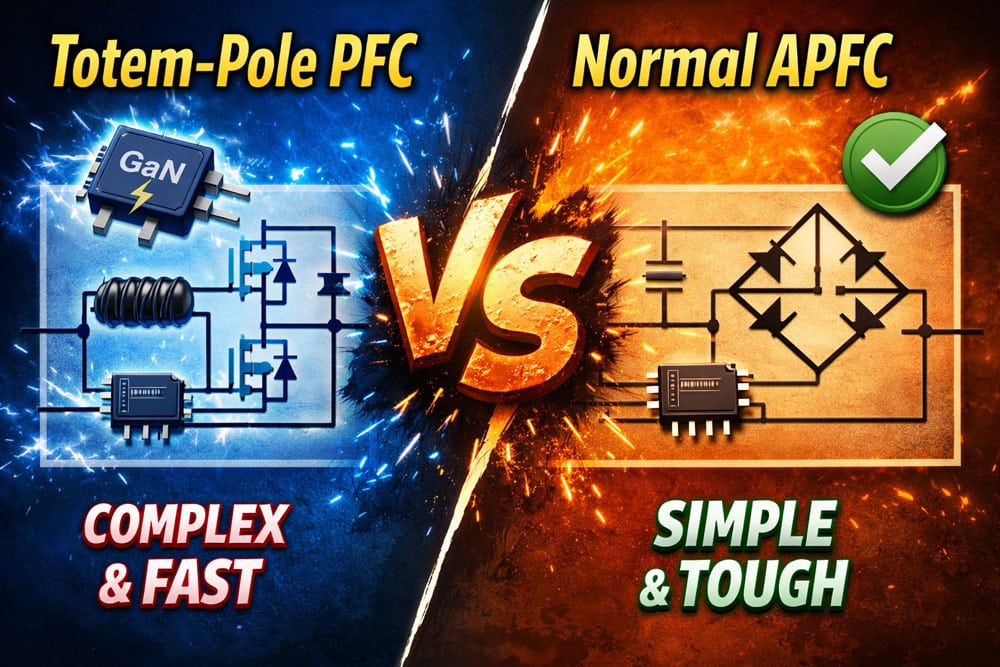

| Topology |

Primary side: APFC, Half-Bridge & LLC converter

Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 6x Toshiba TPHR8504PL (40V, 150A @ 25°C, Rds(on): 0.85mOhm) |

| 5V & 3.3V | DC-DC Converters: 4x UBIQ QN3107M6N (30V, 70A @ 100°C, Rds(on): 2.6mOhm) PWM Controller(s): UPI Semi uP3861P |

| Filtering Capacitors | Electrolytic: 4x Nichicon (3-6,000 @ 105°C, HD(M)), 3x Rubycon (6-10,000 @ 105°C, ZLH) 1x Rubycon (2-10,000 @ 105°C,YXF) 2x Nippon Chemi-Con (105°C, W) Polymer: 31x FPCAP, 2x Nippon Chemi-Con |

| Fan Controller | Microchip PIC16F1503 |

| Fan Model | Corsair NR140HP (140mm, 12V, 0.33A, Fluid Dynamic Bearing Fan) |

| 5VSB Circuit | |

| High Side Rectifier |

1x SMC RS1M (1000V, 1A @ 100°C)

|

| Standby PWM Controller | On-Bright OB2365T |

Channel Well Technology provides the platform, the same OEM that manufactured the previous generation of RMx units. CWT also makes the RMx Shift units. The RMx platform is different from the RMx Shift one, which is expected given the different placement of the modular board. The new RMx platform looks overloaded with parts, although the PCB’s dimensions are normal, and several daughter boards are used to save some space. Given the PSU’s efficiency, the heatsinks are large enough to take some burden off the fan’s shoulders for reduced noise output. The electrolytic caps on the secondary side are not blocked from the fan’s airflow, and they are of high quality. Although polymer caps are preferred for ripple filtering because of their increased tolerance to high operating temperatures and their high ripple current ratings, still, their increased cost and reduced capacitance make the electrolytic caps a requirement for every PSU. To cope with increased transient loads, besides a high-speed response, you also need increased capacitance on the secondary side, and that is where the electrolytic caps are required since they offer a high price per capacitance ratio.

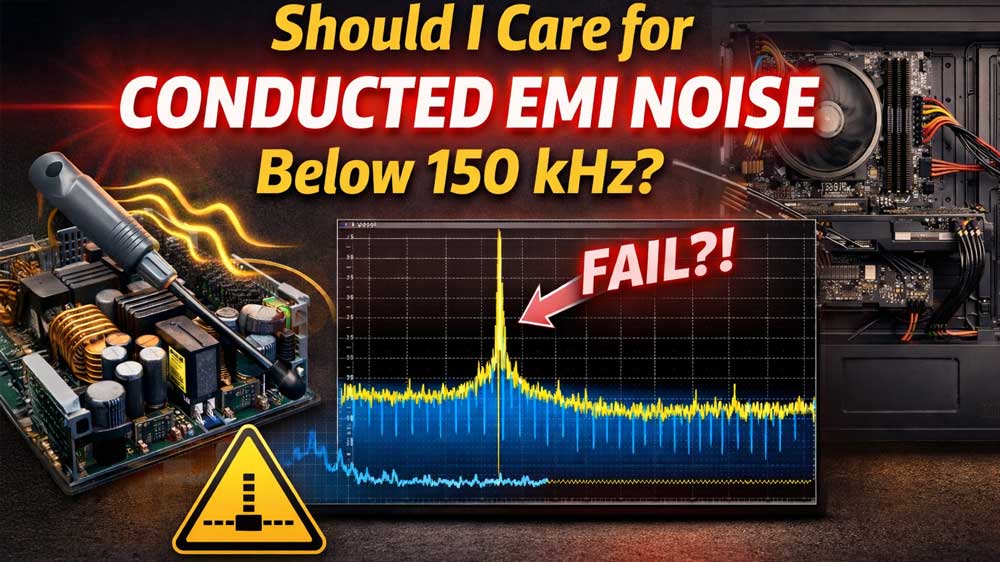

The build quality is high, with good parts everywhere and excellent soldering quality on the PCB. The design follows the modern trend, with an APFC converter, half-bridge topology, and an LLC resonant converter on the primary side. On the secondary side is a synchronous rectification scheme for the 12V rail and a pair of DC-DC converters for the minor rails. The PSU also uses a Microchip MCU to control the fan’s speed.

The fan is the usual aspect: the Corsair NR140HP which uses a fluid dynamic bearing that won’t bother you at low speeds.

Wrong inrush current listed for this model? Cybernetics shows 101.6A, which is super high:

https://www.cybenetics.com/evaluations/psus/2399/

Cyben has revised its inrush current measurements on almost all PSUs, and re-tested them. New data is available for all of them. In my reviews no time to do so, I still use the previous inrush current measurements, sorry.

Is RM850X SHIFT (white color) and this RM850X the same model?

The RM850X SHIFT (White color) is the only available unit here in the Philippines.

Which one is better? Thank you, Sir.

Nope, they are not the same. Both are good; it depends on whether you need to use the shifted modular panel or not.

Hello, im having a hard time deciding about this PSU for $150 or the Deepcool PN850M for only $100, what would you recommend?

50 dollars for a PC part you will keep for at least 3-5 years. I wouldn’t give it much thought for the Corsair model.

Hi Aris, between corsair RM850X and nzxt C850 (both atx3.1 and same price) which one you recommend?

Sir i bought this psu,m not a techie but i notice small differences. The unit i recieved has Black fan instead White which is not an issue tho. The thing is while i am gaming the 12v rail on the cpu drops to 11.952V and the gpu drops to 11.920 or even lower sometimes checked on HWMONITOR app. My pc has Ryzen 5 7600x paired with RTX 5060 so the system is not very demanding. Just now i tested the same with multimeter this time,and i found the idle voltage was 11.97V and when i ran CINEBENCH R23 and FURMARK both at the same time the voltage drops to 11.94 and it was stable at that point. My concern is it should sit little above 12V while the system is in idle right? in my case its already lower than 12V. is it concerning?by the way my pc is stable. The test i did is on a single 8pin pcie cable.

I don’t trust mainboard sensors. Even a cheap multimeter is way better than them.

Thankx for the info. I have tested the same with a good multimeter as well. And the idle voltage was 11.93v bit lower than what I saw on hwinfo. And it drops even further while gaming. Also heard low pitched ‘zzzzzz’ noise coming. May b coil whine.

I had coil whine in my RM850x. It was quite noticeable during idle, so I returned it.

Would be interesting to know what percentage of these PSUs have coil whine.

Hi, what is that knob for? If I turn it to the right, I hear a loud fan sound, if I turn it to the left, I don’t hear the fan sound, but I hear a DIDA sound. Is this to turn off the fan? My power supply is RM1000X.

it sets the minimum fan speed

Hello Aris, can you tell, what is the minimal fan speed to set via fan knob? Is it still quiet? As I found out, Corsair set minimal fan speed in their PSu to +/- 40%. Thank you for the answer.

I don’t remember to be frank, but I don’t believe that Corsair would have loud the minimal fan setting on this unit. They use PWM fans which can go very low in speeds without any probs.

Hola aris, soy de colombia estoy entre Corsair RM850x ATX v3.1 $169 vs nzxt c1000 gold $164 cual me recomiendas

Hi! I would go for the C1000 most likely because of the 150W more.

Hello aris , about the inrush current of CORSAIR RM850x , it was very low according to your observation and you were not able to get meaningful readings , can you explain this in detail , i know that the inrush current should be as low as possible , waiting for your reply .

thanks

Hi! In some PSUs, the NTC thermistor does an excellent job of restricting inrush currents, so we don’t have a solid reading to present. This is a rare case, but it happens.

thanks for replying Aris , you are doing great job with detailed analysis of PSU , it is really helping me in selecting proper PSU, i will go for CORSAIR RM850x , if you have any suggestion it will be really helpful .

Can you recommend something else for low inrush current? I think this rm850x has very high inrush current:

https://www.cybenetics.com/evaluations/psus/2399/

I have revised my inrush current methodology and all new data is completely different. Please check a most recent PSU review.

Thank you!

Hi Aris. What better Corsair RM850x or Asus rog strix platinum 850W? Corsair cost 170$, Asus 198$. Thanks!

I would go for the Corsair RM850x (ATX v3.1)

Hi Aris,

I’m going to buy a Corsair rm850x but you don’t have an Amazon link to it. Do you still get credit if I hit their site through your link to another product and browse for what I want?

Thanks for all your work. It’s PLENTY worth supporting. Put up a sponsorship link, as well!

Thank you Alan! Here is the link https://amzn.to/4hiXEHu

man did you buy it? How’s it going today? I’m looking forward to buying it, but I can’t decide.

It is a review sample so I only used for the review.

Thank you for the review, Aris. I can’t decide which PSU to buy, the Corsair RM850x (2024) or the Super Flower Leadex VII XG 850W. They are both at the same price in my country. Which one do you think is the better one and you would take?

Another hardware site, LTT, mentions that the previous version doesn’t have UVP but instead “CFP”? Corsair mentions this has UVP (as required by ATX specification), and I was wondering if you test for that?

don’t follow what LTT says, sorry. I can only know what I do in my lab.

This PSU was the worst I’ve bought over 20 years of building PC’s every few years. The cables smelled of cheap plastic, and the unit itself let off a nasty burnt cable smell, neither of which dissipated away after running it for 3 days under a ventilator. Sent it back to the shop, hopefully getting a refund. Not buying corsair PSU’s anymore for a long time.

Weird, we didn’t notice this smell, which might exist indeed in some PSUs.

I sent it for RMA, they replaced it, just now opened the replacement box, the same nasty smell is on the cables on a brand new unit. Won’t even bother installing it, this time will make sure to ask for a refund.

I just bought this PSU, and it was in fact noticeably stinky. Like a factory/chemical stink, similar to how some other electronics and plastic products smell, but way stronger.

My room stank for about a day, now it seems to be gone, but no burning smell was present.

I sniffed about, and, while the PSU and cables themselves smell unpleasant, the little paper safety manual thing in the box is awful. It’s probably printed with the sloppiest drippings of landfill on paper made from recycled diapers. My guess it combined with the normal new component smell and mixed into a potent carcinogenic fart-in-a-box.

Hey Aris, thank you for the review. After my long research and your articles, I finally bought this product (it finally arrived in my country). Is it a problem if the 3.3V channel drops below 3.2? If it is a problem, what causes it?

weirdingly enough, I just noticed this post. 3.3V rail is not used so hard anymore.