Part Analysis

| General Data | |

| Manufacturer (OEM) | CWT |

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 6x Y caps, 3x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | 2x NTC Thermistor SCK-075 (7 Ohm) & Relay |

| Bridge Rectifier |

2x Shindengen LL25XB60 (600V, 25A @ 113°C)

|

| APFC MOSFETs |

2x Infineon IPW60R099P6 (600V, 24A @ 100°C, Rds(on): 0.099Ohm)

|

| APFC Boost Diode |

2x Infineon IDH10G65C6 (650V, 10A @ 145°C)

|

| Bulk Cap(s) | |

| APFC Cut-Off |

Sync Power SPN5003 (reducing no-load consumption)

|

| Main Switchers |

4x Alpha & Omega AOTF29S50 (600V, 18A @ 100°C, Rds(on): 0.15Ohm)

|

| Digital Controllers | 2x Texas Instruments UCD3138A |

| MCU |

Microchip PIC32MM0064GPM036

|

| IC Driver | 2x Silicon Labs Si8233BD |

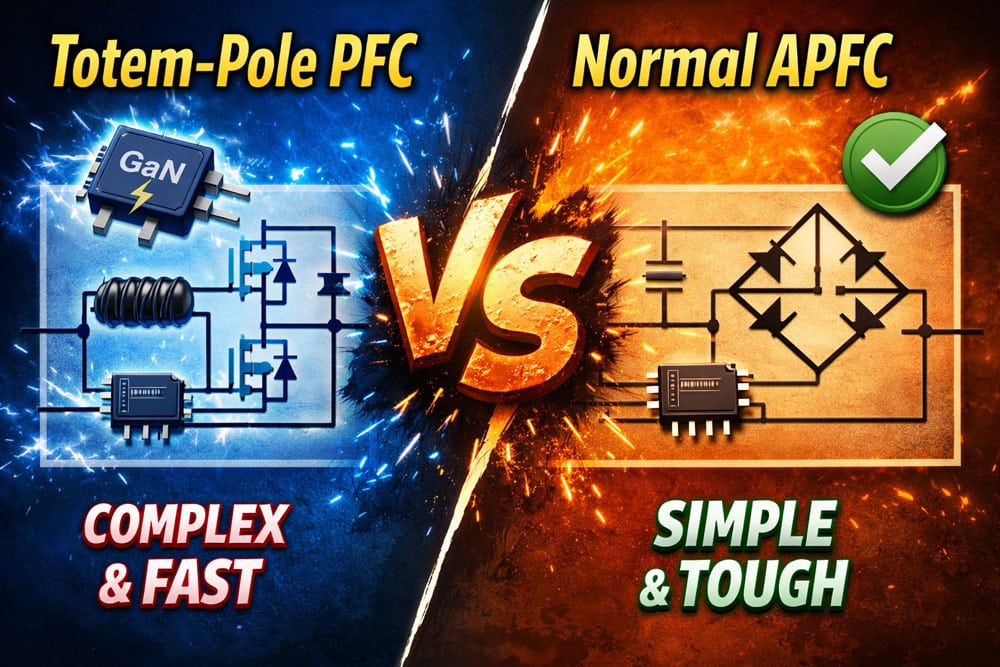

| Topology | Primary side: Digital, Interleaved PFC, Full-Bridge & LLC Resonant Converter Secondary side: [12V] Synchronous Rectification & [Minor Rails] DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 12x Infineon BSC014N06NS (40V, 182A @ 100°C, Rds(on): 1.45mOhm) |

| 5V & 3.3V | DC-DC Converters: 6x UBIQ Semi QN3107M6N (30V, 70A @ 100°C, Rds(on): 2.6mOhm) PWM Controller(s): UPI-Semi uP3861P |

| Filtering Capacitors | Electrolytic: 6x Nippon Chemi-Con (@ 105°C, W) 2x Rubycon (6-10,000h @ 105°C, ZLH) Rubycon (4-10,000h @ 105°C, YXF) Nichicon (5-6,000 @ 105°C, HV(M)) Polymer: 7x Nippon Chemi-con, 29x FPCAP |

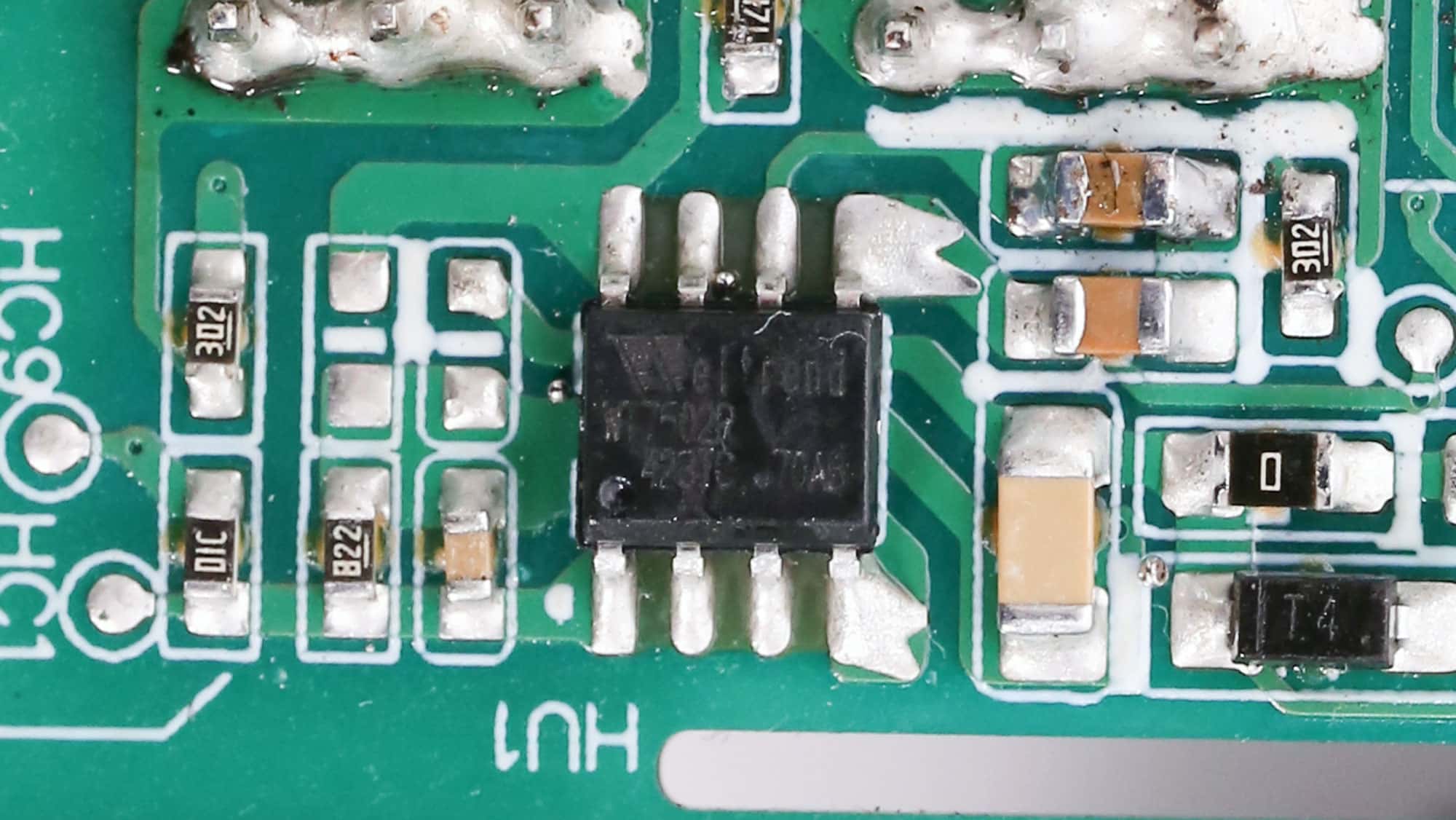

| Supervisor IC | Weltrend WT7502R (OVP, UVP, SCP, PG) |

| Fan Controller / Micro Controller | Microchip PIC32MM0064GPM036 |

| Fan Model | Corsair NR140P (140mm, 12V, 0.22A, Fluid Dynamic Bearing Fan) |

| 5VSB Circuit | |

| Synchronous Rectification IC |

Leadtrend LD8926AA1

|

| Standby PWM Controller |

On-Bright OB2365T

|

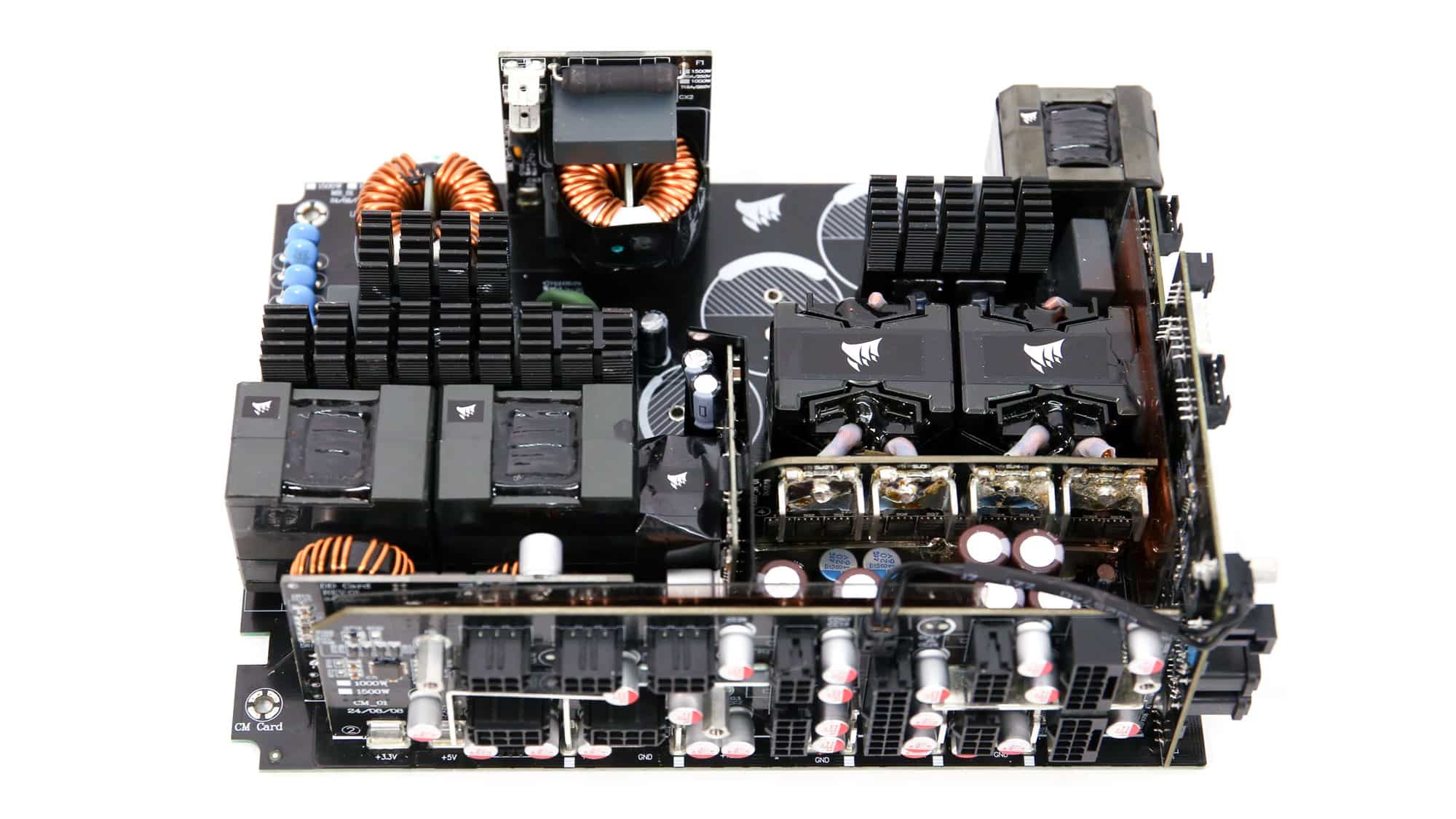

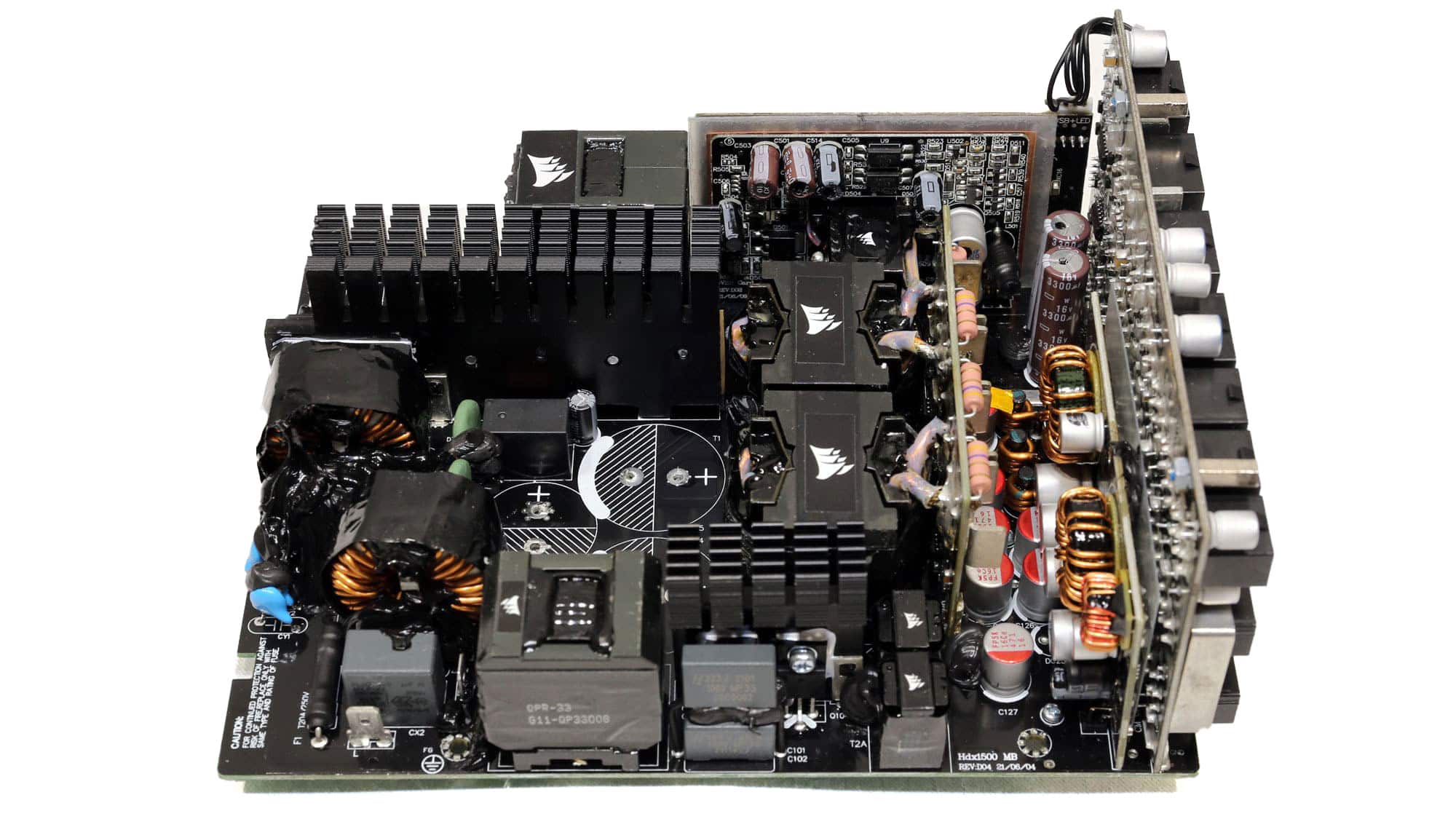

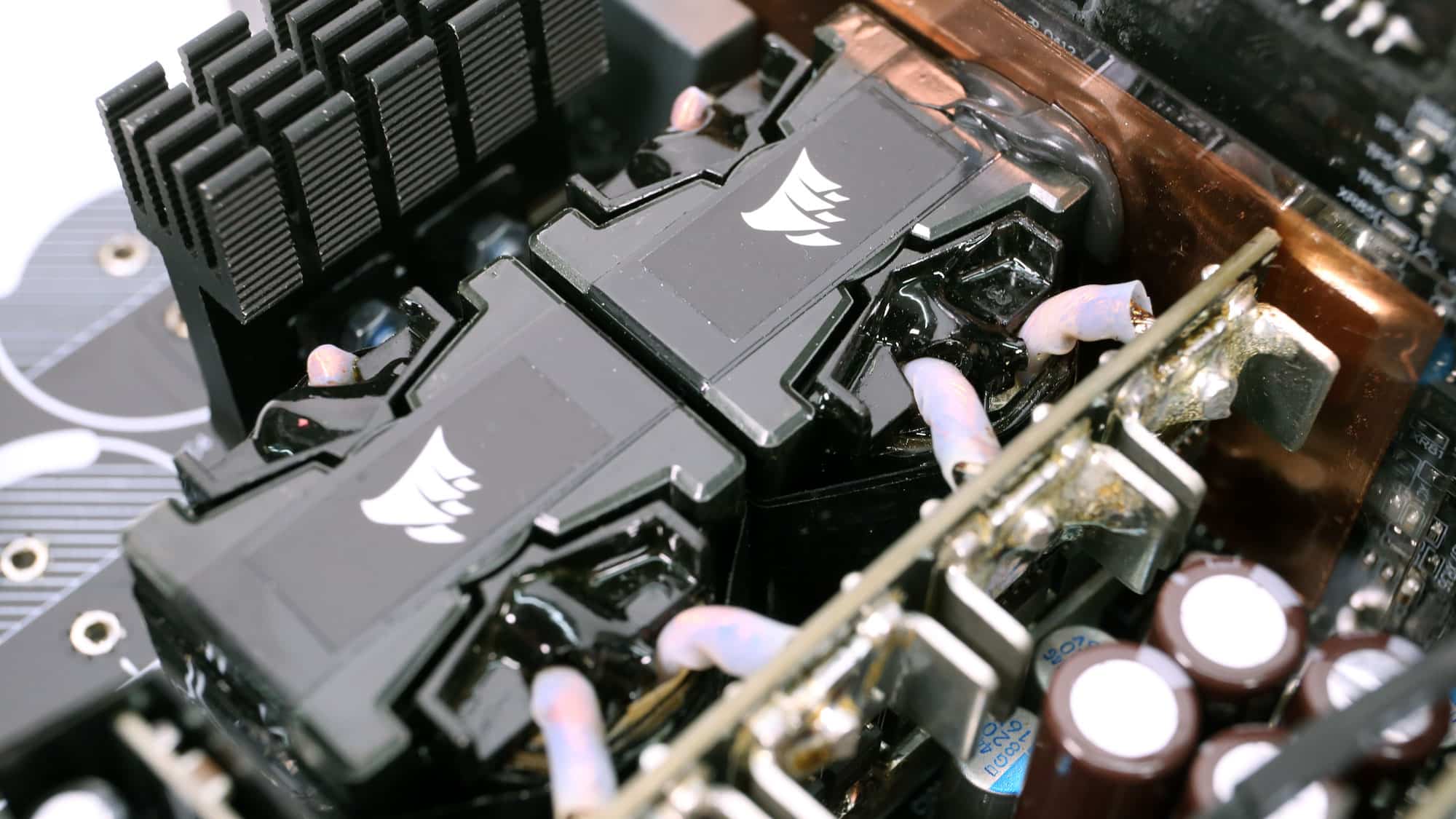

First, the 1200W and 1500W HXi Shift models use a different platform from their 1000W sibling. CWT provides a semi-digital platform, with the primary side and part of the secondary handled by digital controllers. Only the minor rails and 5VSB use analog controllers; otherwise, this platform would be fully digital. While the HX1000i uses a half-bridge topology on its primary side, the higher-end models use a full-bridge topology, better suited to high-power output. The heatsinks on the primary side are large enough for a modern, efficient platform, while those on the secondary side are tiny. CWT typically uses small heatsinks on the secondary sides of its high-end implementations to lower production costs and save valuable PCB space.

Overall, the build quality is high, as expected in such an expensive PSU. All parts, including Infineon FETs and Japanese capacitors from Chemi-Con, Nichicon, and Rubycon, are high-quality. The cooling fan is also the typical NR140P, using a fluid dynamic bearing. Although CWT started producing its fans, Corsair still wants even higher performance and quality.

The Shift model’s design is clearly different from that of the HX1500i, which makes sense given the modular panel’s shift. Still, many of the same parts are used, including the digital controllers and the MCU.

The transient filtering stage contains all the necessary components to block both incoming and outgoing EMI emissions. Typically, it starts at the AC receptacle and continues on the main PCB.

There is an MOV to protect from voltage surges and two NTC thermistors with a combined resistance of 14 ohms. Moreover, a bypass relay supports the NTC thermistors.

The two Shindengen LL25XB60 parallel bridge rectifiers can handle up to 50A together.

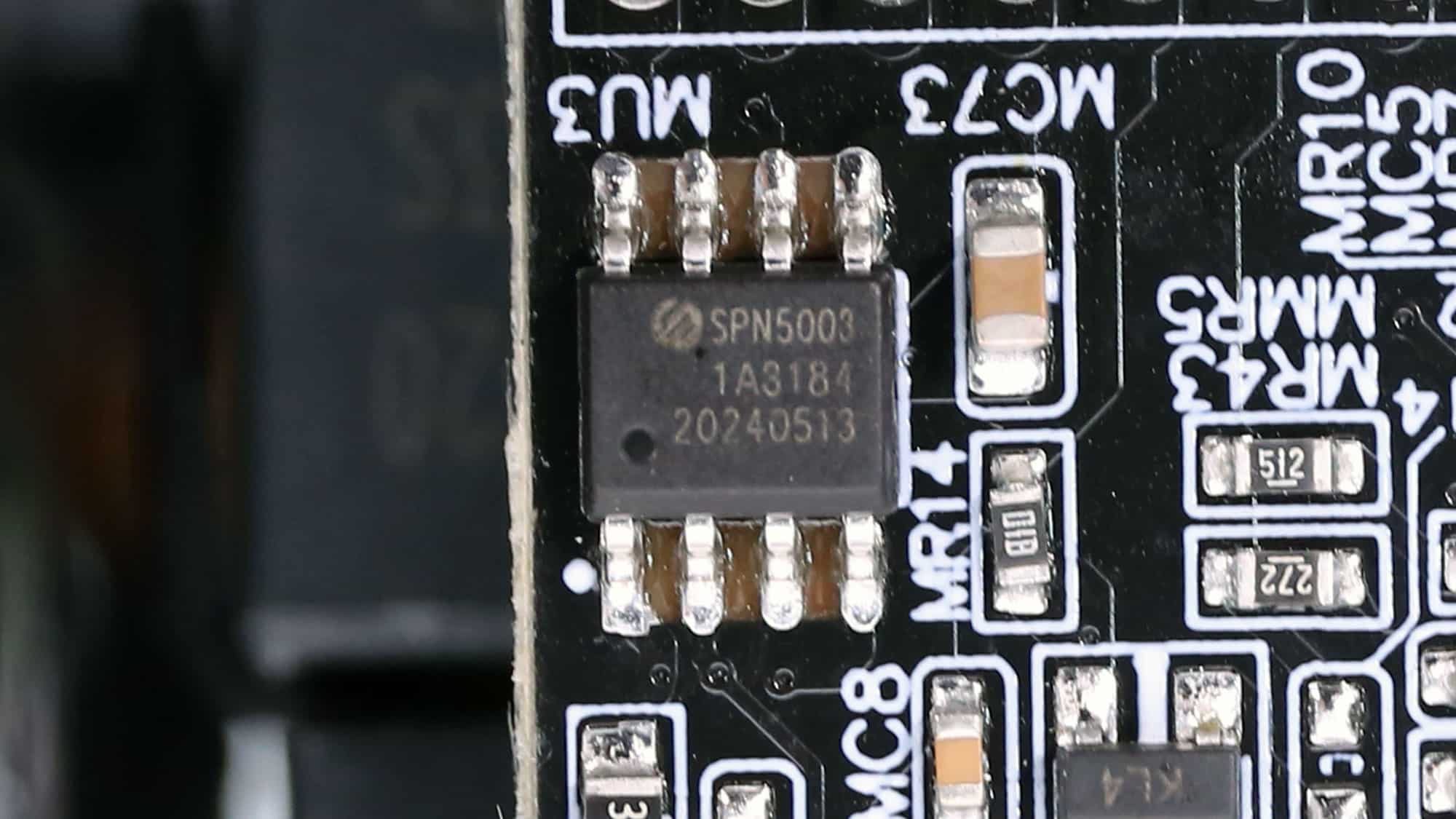

To reduce vampire power, CWT uses a Sync Power SPN5003 IC, which essentially cuts off the APFC converter when only the standby circuit is active.

The interleaved APFC converter uses two Infineon IPW60R099P6 FETs and two Infineon IDH10G65C6 boost diodes. Nippon Chemi-Con and Rubycon manufacture the bulk capacitors. Their combined capacity is 1710 μF, and both are rated for 2,000 hours at 105 °C. The voltage rating is 420V, which is higher than the APFC’s DC bus voltage (approximately 380-400V DC).

A pair of digital controllers handles the APFC, the primary switching, and the 12V FETs. We would have a fully digital platform if digital controllers also dealt with the minor rails. The PSU’s brain is a Microchip PIC32MM0064GPM036 MCU, which also handles communication between the system and the PSU’s circuits.

Four Alpha & Omega AOTF29S50 primary-switching FETs are used in a full-bridge topology, and an LLC resonant converter is employed for enhanced efficiency. The main FET drivers are a pair of Silicon Labs Si8233BDs.

The PSU’s main parallel transformers. Their main function is to electrically isolate the primary and secondary sides.

Twelve (eight in the 1200W model) Infineon BSC014N06NS FETs regulate the 12V rail.

Two DC-DC converters generate the minor rails. They use six UBIQ Semi QN3107M6N FETs. The PWM controller is a UPI-Semi uP3861P.

Chemi-Con, Nichicon, and Rubycon provide the electrolytic capacitors. FPCAP and Chemi-Con make the polymer capacitors.

You can find more information about capacitor performance and other specs below:

The standby PWM controller is an On-Bright OB2365T.

The supervisor IC is a Weltrend WT7502R (OVP, UVP, SCP, PG).

Several polymer caps at the face of the modular panel form an extra ripple-filtering layer.

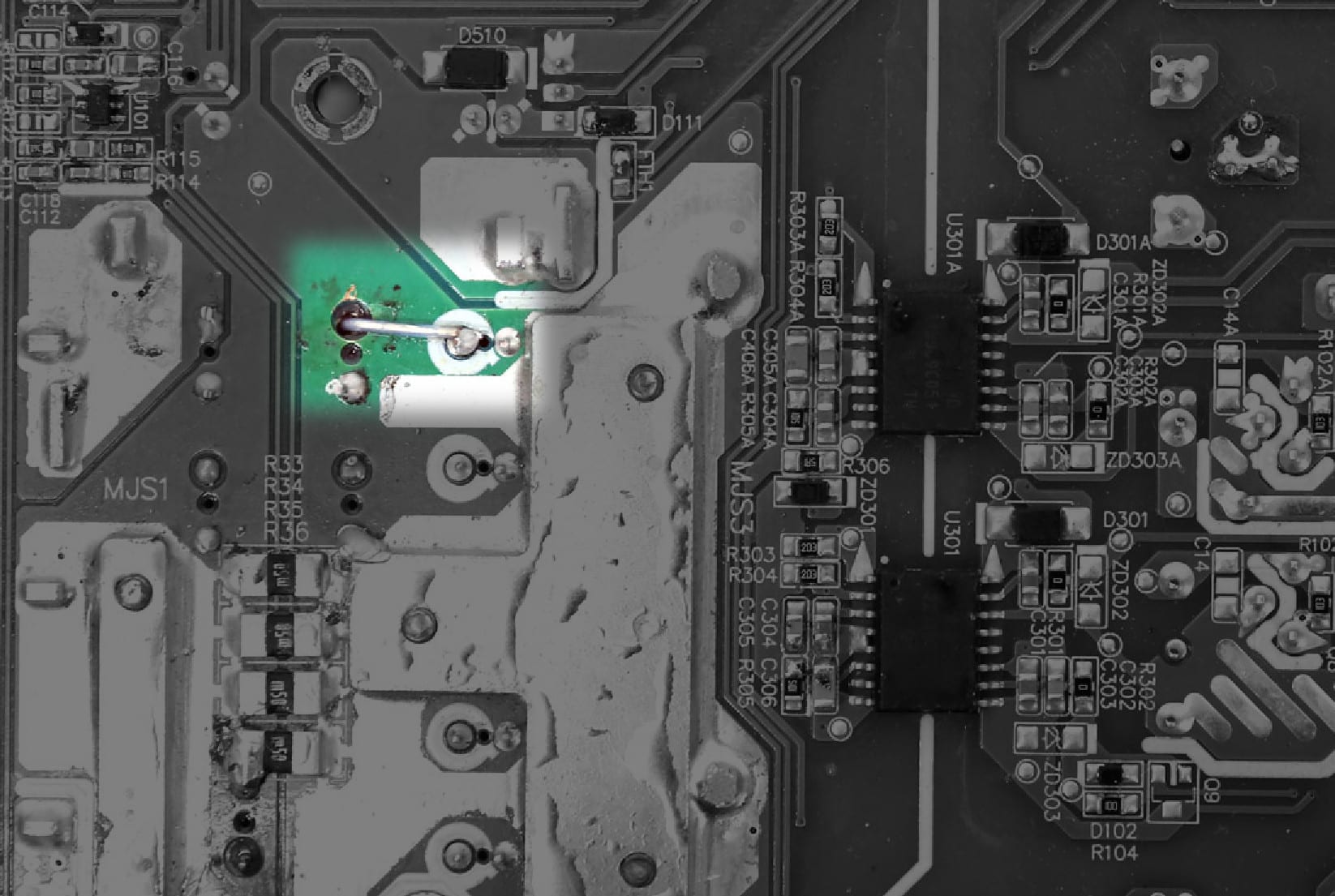

The soldering quality is decent. There are some enhanced PCB traces also, to handle high currents without increased losses.

This “weird” connection existed in my pre-production sample, and it makes sense, since it is not an MP (Mass Production) unit, so some last-minute changes were needed. Note that all tests were conducted with the MP sample, although I used the part analysis of the DVT sample, since I wanted my MP sample to be spotless for re-running some tests if required.

The cooling fan is a Corsair NR140P with a fluid-dynamic bearing.

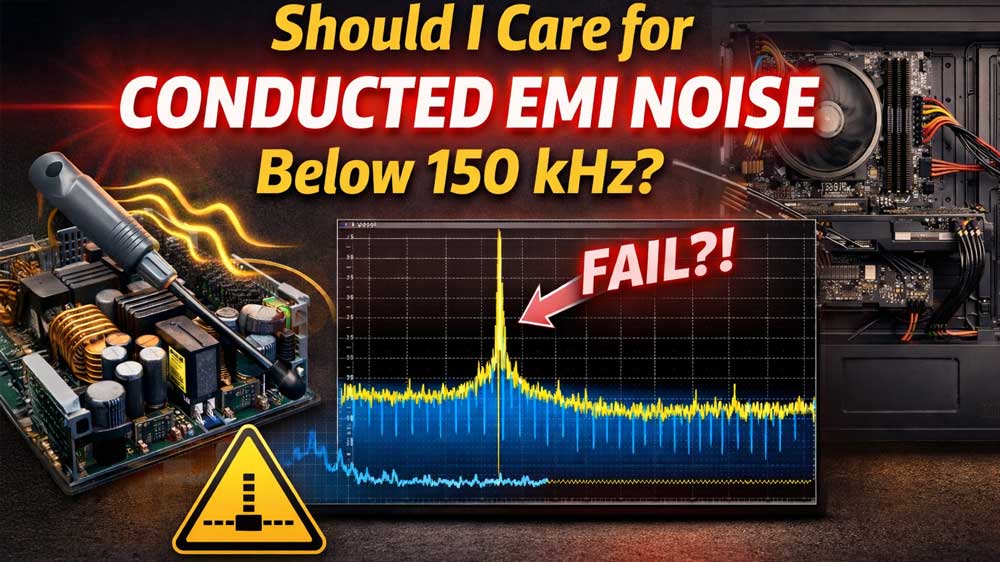

The Aris is probably worth considering ask this. The EMI you tested on this power supply (I’m not an expert on this), is it worth buying, or will the EMI completely ruin this power supply and cause various problems? / Will you update this graph with new samples?

Best regards 🙂

Hi! There’s a controversy there because the OEM says EMI is ok in their measurements, while we found an issue. The problem is we have only 1x sample, so I told them to send several to check whether the problem is in my sample alone.

Hi Aris thanks for reply

So for now this corsair model do not buy or if i purchase same as you unit/batch it’s ok for PC components ?

You most likely won’t have any issues. But I need to figure what is going on.

Why only two 6+2 PCIE connectors? There should be at least three for high-end Radeon GPUs. Is this PSU exclusively for 5090 GPUs?

Most high-end PSUs care primarily for 12V-2×6 compatible GPUs, yes.

hello Aris did some FSP Vita GD PSU had an cybenetics evaluation report, i’ve seen this product have an cybenetics badge yet but i can’t find some data on a cybenetics web https://www.coolaler.com.tw/image/fsp/vita_gd_650w/01.jpg ?

Hi! Cyben has tested them, they just didn’t go public. I will talk to FSP now!

And also needs update for MSI A1250GS https://www.msi.com/Power-Supply/MPG-A1250GS-PCIE5/Overview because i can’t find them on cybenetics web mate thx

This is still under test. We asked for new samples.

I’ve bought HX1500i Shift 2 days after it went on sale. Now one week in and so far so good. Included software, at my near idle load of 160W, shows 88% efficiency which is kind of disappointing. AX1600i at the same load had 94% efficiency, but space was an issue with cables directed to the front = “the normal way”. Those made my plans to build custom LC setup on-hold. HX has the same dimensions but most of the cables are now directed to the side of the case. And here is one more drawback it has – the USB (for communication with motherboard), TACH (for Corsair’s AIO pump) and iCUE LINK (for RGB) connectors are directed to the front! This makes no sense at all. It’s like the entire PCB for this part was done as an afterthought. All of those should be on the side as well. Coirsair is including flat 90 deg iCUE connector, but for USB-C you have to buy an 90 degree adapter on your own. Another thing is the cables that are included are not sleeved, instead they used some kind of rubbery polymer with marks that pretend to give of sleeved visuals. 8-pin PCIe cable also has this ugly loop to the +2 pins just next to the plug because it’s 6 wires but the plug has 8 connectors (they extended from 6 to additional 2 just next to GPU’s plug and it’s really ugly). But hey they probably saved 10 cents on the wires! Any noises, coils, crickets or whatever – I don’t hear anything like that. But I still suggest to setup fan to do the minimal spin (15% setting is like 450RPM) so the electronics inside operates in lower temp and has longer lifespan.

One more thing I noticed, it may be just my imagination, but I have 4 enterprise class high capacity WD HDD’s and when I turn on the PC it gives of of feeling like it now takes longer time for the HDD’s to reach the operating speed. Maybe it’s in-rush load handling or something (I could try and measure the current on the rig, but I doubt my $5 multimeter will catch anything useful).

Also one more thing to note. I’ve bought it on October 15. All the promo materials on Corsair website (both English version and my native language site version) were showing that it has Cybenetics Platinum certificate. Even when I visited Corsair website one day earlier it was the same. However when I checked Cybenetics certification website nothing was there for HX1500i Shift. There was only the regular HX1500i listed. And now certificate is present but the date on it is 17 October.

A very disappointing PSU… can you say what’s next on the list?

Thermaltake Toughpower PT

I mean 0.928… I typed it wrong

Hello Aris, I think there’s a small mistake in the Pcyes Aether 1000W certification. At 230V the certification shows Cybernetics Silver, but it has an efficiency of 90.459% at 230V, a little below

Please note that efficiency levels also depend on other factors, such as PF and 5VSB efficiency, as well as vampire power, in addition to overall efficiency.

Hmm. I didn’t know that. I thought 89-91% was considered gold at 230V, I didn’t know there were other details.

That’s the PSU I was talking about. https://www.cybenetics.com/evaluations/psus/2434/

I checked, you’re totally right. Her overall efficiency is gold and the Vsb efficiency is also above 75%, but her PF is below 0.930 (gold), hers is at 0.929. I hope they fix this… Thank you very much and I apologize for the inconvenience.

I mean 0.928… I typed it wrong