Part Analysis

| General Data | |

| Manufacturer (OEM) | Cooler Master |

| Platform | MPS-D001-AFAP |

| PCB Type | Double-Sided (Four-layer board) |

| Primary Side | |

| Transient Filter | 2x Y caps, 1x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | 1x NTC Thermistor SCK20100 (10 Ohm @25°C) & Relay |

| Rectifier MOSFETs |

4x Infineon IPT60R022S7 (600V, 23A @ 140°C, Rds(on): 0.0.22Ohm)

|

| APFC MOSFETs |

2x Infineon IMW65R072M1H (650V, 18A @ 100°C, Rds(on): 0.094Ohm)

|

| APFC Driver |

Infineon 2EDN7524F

|

| APFC Boost Diode |

1x Infineon IDW10G65C5 (650V, 10A @ 130°C)

|

| Bulk Cap(s) |

2x TDK B43641 (450V, 560uF each or 1120uF combined, 2000h @ 105°C)

|

| Main Switchers |

4x Infineon IPW60R070CFD7 (650V, 31A @ 25°C, Rds(on): 0.07Ohm)

|

| Driver ICs |

2x Infineon 2ED21814S06J (650V, 31A @ 25°C, Rds(on): 0.07Ohm)

|

| APFC Controller |

Infineon ICE3PCS01G

|

| Resonant Controller |

Infineon ICE2HS01G

|

| Primary Side MCU |

NXP MC9S08SH8CWJ

|

| Topology |

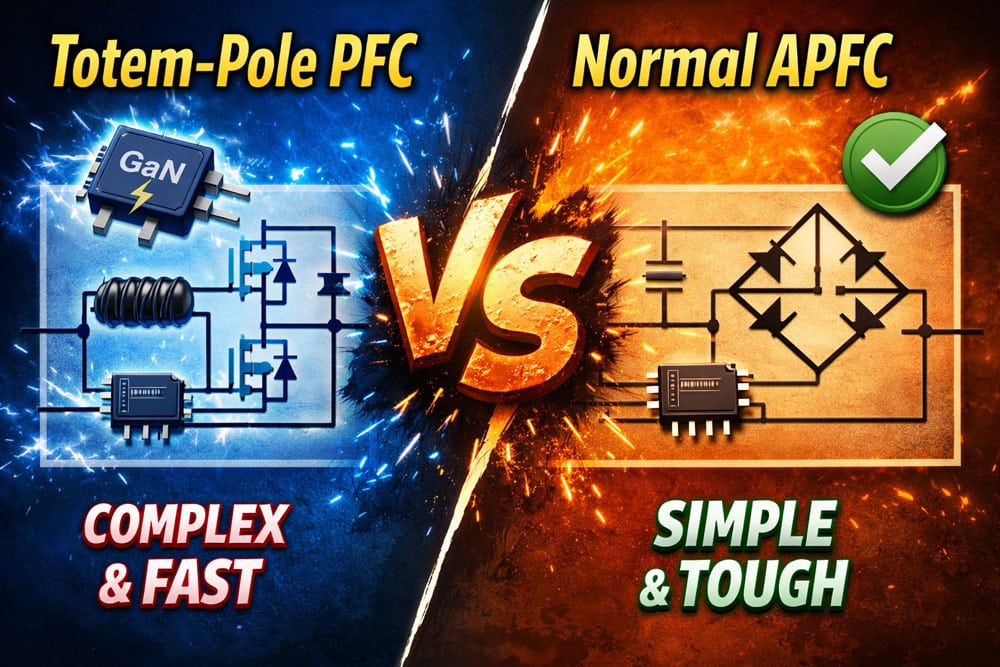

Primary side: Bridgeless PFC, Full-Bridge & LLC converter

Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 12x Infineon ISC010N04NM6 (40V, 201A @ 100°C, Rds(on): 1.0mOhm) |

| 5V & 3.3V | DC-DC Converters: 6x Infineon ISC011N03L5S (30V, 100A @ 100°C, Rds(on): 1.1mOhm) PWM Controller(s): 1x |

| Filtering Capacitors | Electrolytic: 2x Rubycon (6-10,000 @ 105°C, ZLH), Polymer: 42x Nippon Chemi-Con, 7x |

| Supervisor IC | Weltrend WT7502 |

| Secondary Side MCU | Silicon Labs C8051F380-GQ |

| 5VSB | |

| TVS Diode |

1x SMBJ150A

|

| Low Side Rectifier |

DK DK5V45R05M (45V, Rds(on): 5mOh)

|

| Standby PWM Controller | Infineon ICE5QR1680BG |

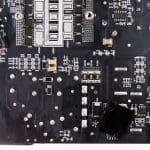

Performing part analysis on this platform was not easy because the huge heatsinks obscured most parts’ views. Removing the beefy heatsinks without destroying the PCB or some sensitive parts is daunting, so we did everything we could without removing them. Thankfully, the PCB is large enough, providing enough space for airflow and for the interested reviewer to poke around and identify parts.

The platform’s design is clean and interesting, and the large heatsinks covering most parts are necessary since there is no forced cooling. Moreover, the secondary side is clear and only has a pair of electrolytic capacitors, leaving ripple filtering to polymer caps tolerant to high operating temperatures. Cooler Master paid special attention to the cooling of the PFC’s choke and of the main transformer since inductor core saturation depends on the operating temperature. You don’t want any of these two to saturate since when this happens, the inductance will be greatly reduced, and the ability to suppress the current is lost. In other words, when an inductor is saturated, it doesn’t behave as an inductor but as a small resistor because of the conductor’s resistance, and this can create a fatal short-circuit, which will blow the FETs before the inductor.

The build and soldering quality are impeccable, and Cooler Master’s PSU production line seems to be top-notch. A bridgeless PFC converter, a full bridge topology, and an LLC resonant converter are used on the primary side. A synchronous scheme is used on the secondary side, and two DC-DC converters generate the minor rails.

A weird thing in this PSU is that although it has two MCUs, which could handle the entire primary side and a part of the secondary side, still analog controllers are utilized to control the APFC, the main and the 12V FETs, and the minor rails. Normally, the digital controllers should control the APFC converter, the main, and 12V FETs, but they could also handle the FETs regulating the minor rails. Still, special firmware is required for this, and it seems CM is not ready yet to provide this firmware. So, unfortunately, the MCUs are only used for communicating purposes between the PSU and the system and for sensor readings. The PSU’s cost could come down if the MCUs were omitted from the moment the PSU’s vital functions rely on analog controllers. Hopefully, CM will improve this design and get rid of the analog controllers instead, further improving performance and lowering the production cost.

At the PCB’s solder side, we find all FETs regulating the 12V rail, which are cooled down by the PSU’s chassis, which incorporates a strong cooling solution with four heat pipes and a block.

I don’t agree with the warranty criticism. It is stated definitively without proof:

“Such a long warranty period will eventually create problems for both the brand and consumers”

Will? How about “might”? It’s actually refreshing to see a company stand behind their product. 15 years is not an unreasonable lifespan for a PSU.

With low loads the efficiency is terrible, much worse than many psu that are around at better prices. Together with other shortcomings I honestly do not understand how it could have taken the editor choice…. incredible. They did not take much more performing power supplies.

why was my comment deleted?

Is it necessary to have a case that allows natural convection, that is, one that has an opening for airflow in the part above the PSU? For example, the be quiet! Dark Base Pro 901 is not compatible with this PSU because it does not have openings on the shroud top?

Yes, this is required else the hot air will be trapped inside the PSU.

Thanks for the review.

Now this in SFX 750-850w and it’s golden.

Even if i had to pay 300€ for a Fanless and no coil whine.

A lot of what makes this sort of thing possible is the somewhat large size, since smaller PSUs need to pack components more tightly which reduces their exposed surface area and therefore cooling potential. This is why SFX PSUs tend to be louder, because the fan needs to spin faster to account for this difference and keep components cool. In other words, less surface area needs more airflow to dissipate heat, while more surface area will need less; this is why passive CPU coolers like the Noctua NH-P1 are so huge, and why rack-mounted servers are able to have such small heatsinks for how power-hungry server hardware can be.

This isn’t to say that a passively cooled SFX unit is impossible, but rather that it would require a lot of development and would have a much lower capacity. After all, safety should be the number one thing when designing (and indeed buying) a new PSU.

honestly I don’t see the point (it’s a showoff most likely), to require as much power you’d need a Threadripper and probably two 4090, there’s no way to cool these down passively

what we need are affordable 400W Passive SFX models instead

We might not need 1100W necessarily, but the smaller 850W model is very welcome and I’ll be buying one of these two when they’re finally available.

I have a RTX 4090 PC with custom watercooling that is completely silent even under heavy load and currently the Seasonic 600W passive PSU. It’s a tad undersized, so I want to upgrade – but for now, the only upgrade path has been the 700W Seasonic. I’m not spending that much money on a 100W upgrade that’ll be useless when GPUs inevitably use the full 600W the new cable can provide.

I do not consider an actively cooled PSU an option because I have yet to see one that’s certain to not add noise to my system at full load.