Part Analysis

| General Data | |

| Manufacturer (OEM) | Gospower |

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV & 1x MPS HF81 (X Capacitor Bleeder) |

| Inrush Protection | 1x NTC Thermistor 16D-20 (16 Ohm) & Relay |

| Bridge Rectifier(s) |

2x GBU2508 (800V, 25A @ 98°C)

1x GPU608 (800V, 6A @ 100°C)

|

| APFC MOSFETs |

2x Infineon IPW60R060P7 (650V, 30A @ 100°C, Rds(on): 0.060Ohm)

|

| APFC Boost Diode |

2x Jilin Sind 60F60WT (600V, 60A @ 135°C)

|

| Bulk Cap(s) |

2x Tokshin Kogyo TK (450V, 680uF each or 1360uF combined, 2000h @ 105°C, LGW)

|

| Main Switchers |

2x Infineon IPW60R060P7 (650V, 30A @ 100°C, Rds(on): 0.060Ohm)

|

| APFC Controller | |

| Resonant Controller |

Champion CU6901VAC

|

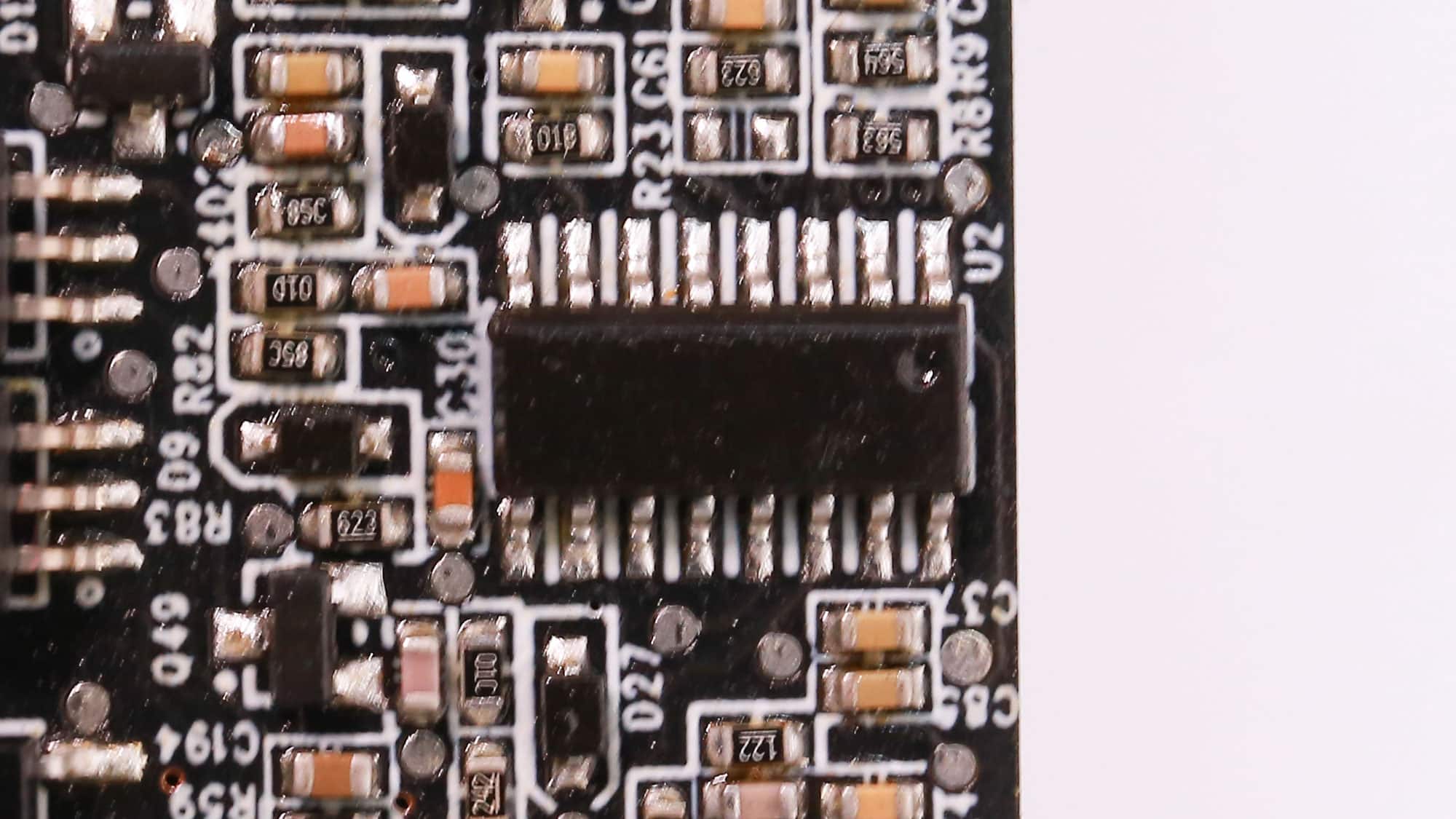

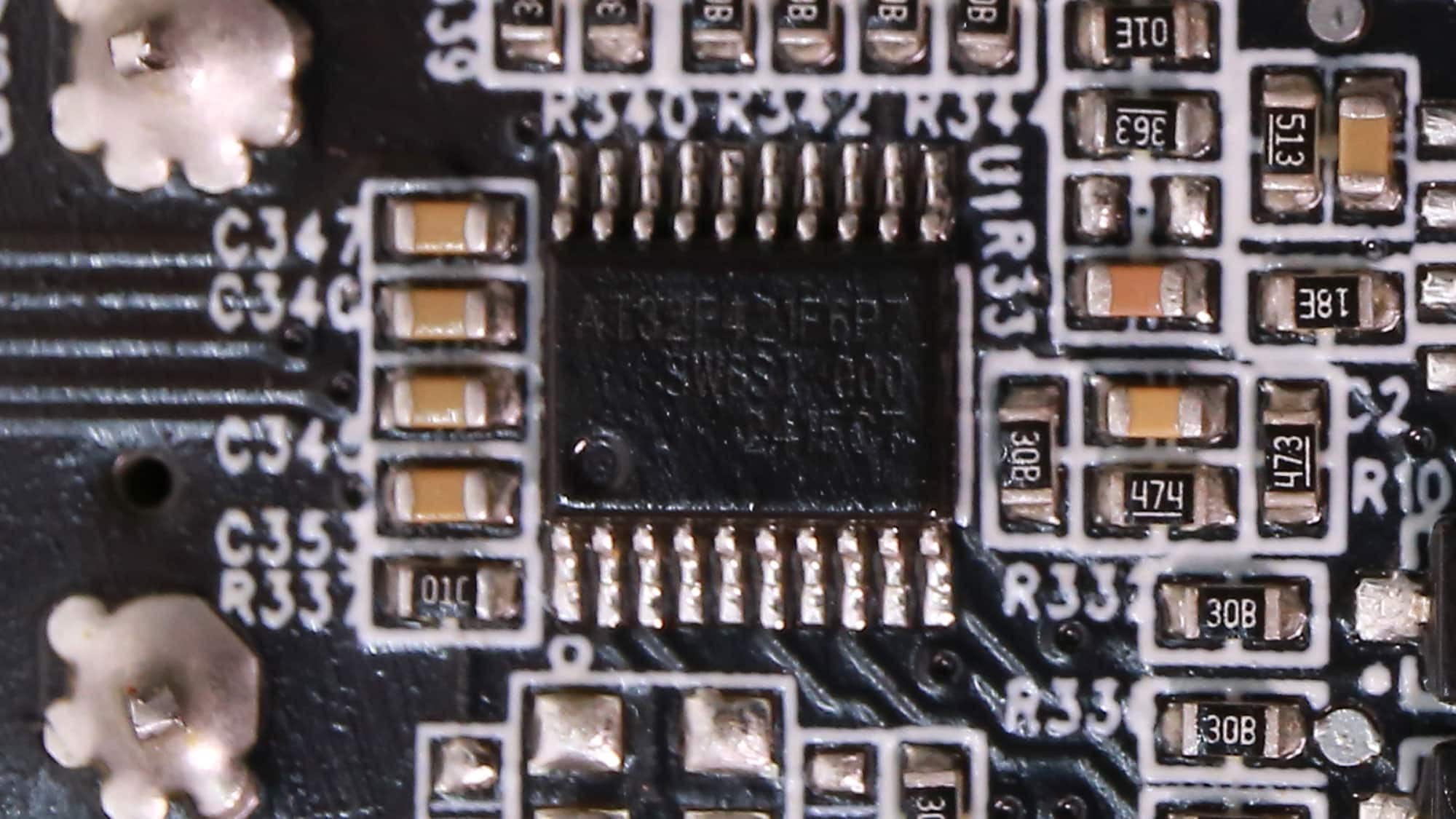

| MCU |

Arery AT32F421F6P7

|

| Driver IC |

2x Texas Instruments UCC27524

|

| Topology |

Primary side: Interleaved PFC, Half-Bridge & LLC Resonant converter

Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

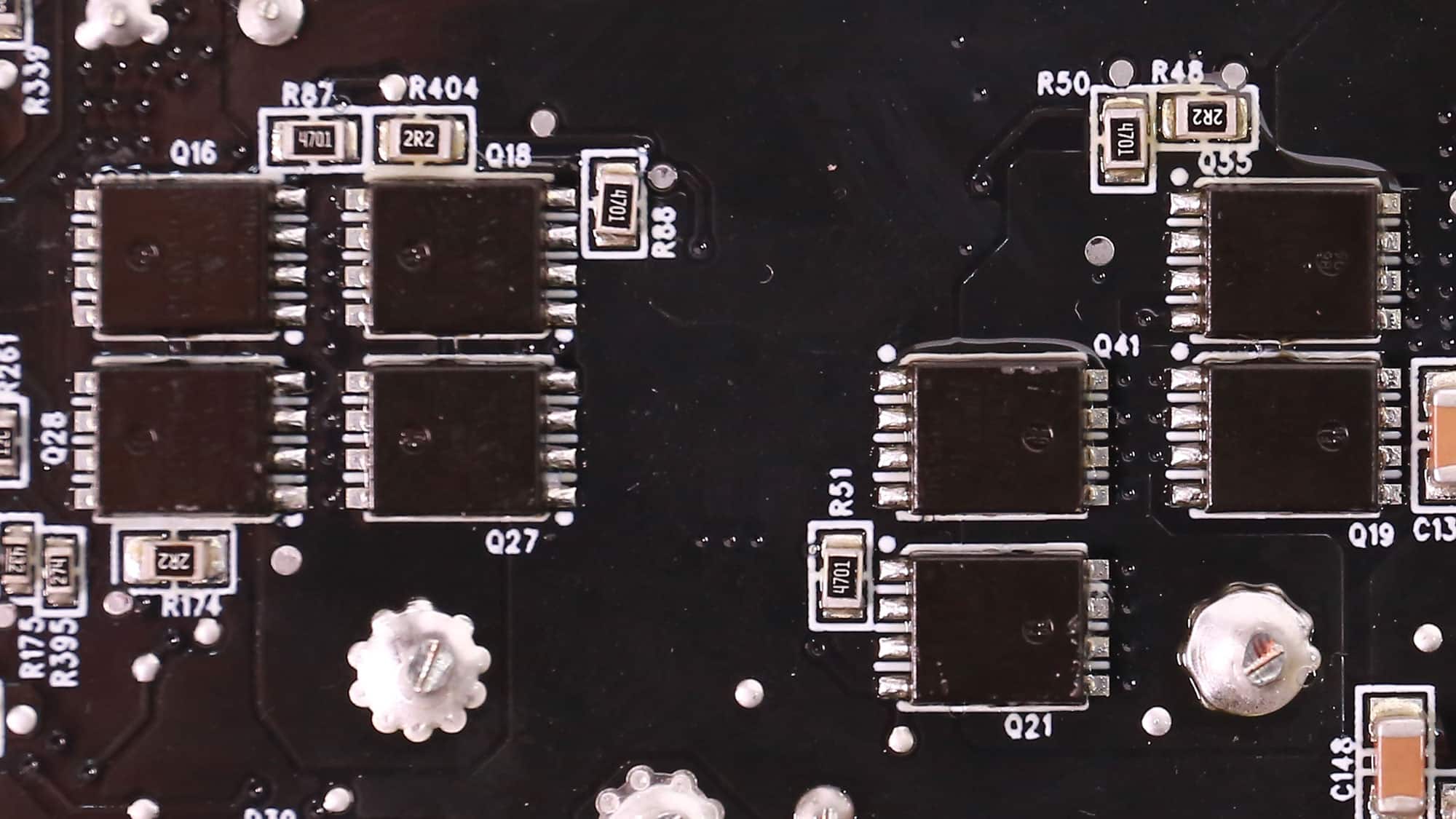

| +12V MOSFETs | 12x NCEPower NCEP40T15GU (40V, 106A @ 100°C, Rds(on): 1.35mOhm) |

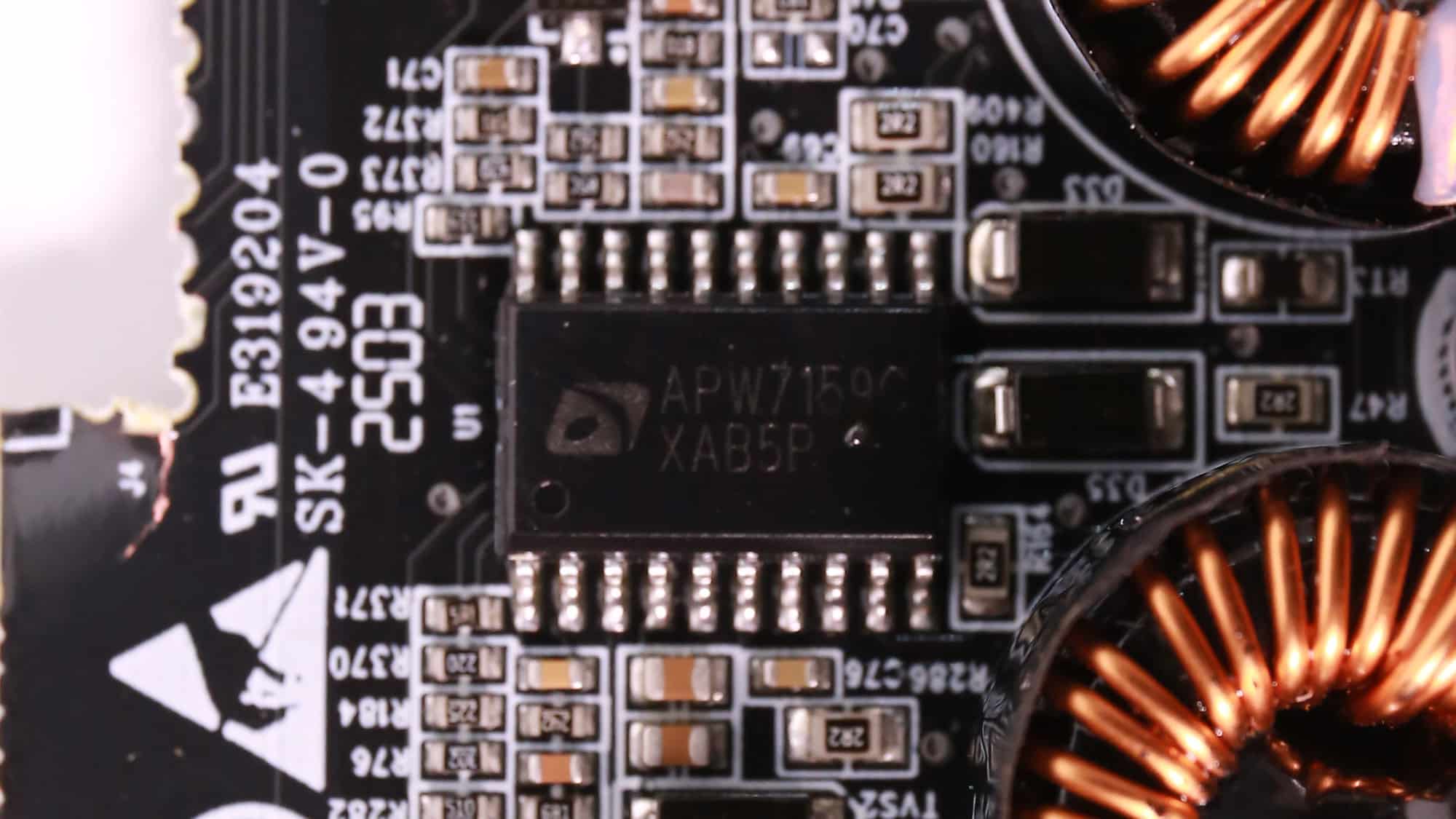

| 5V & 3.3V | DC-DC Converters: 8x IPS FTG014N04SA PWM Controller(s): Anpec APW7159C |

| Filtering Capacitors | Electrolytic: 20x Rubycon (4-10,000h @105°C, YXJ) 4x Rubycon (2-10,000 @ 105°C, YXF) 3x Rubycon (6-10,000h @105°C, ZLH) Polymer: 50x FPCAP |

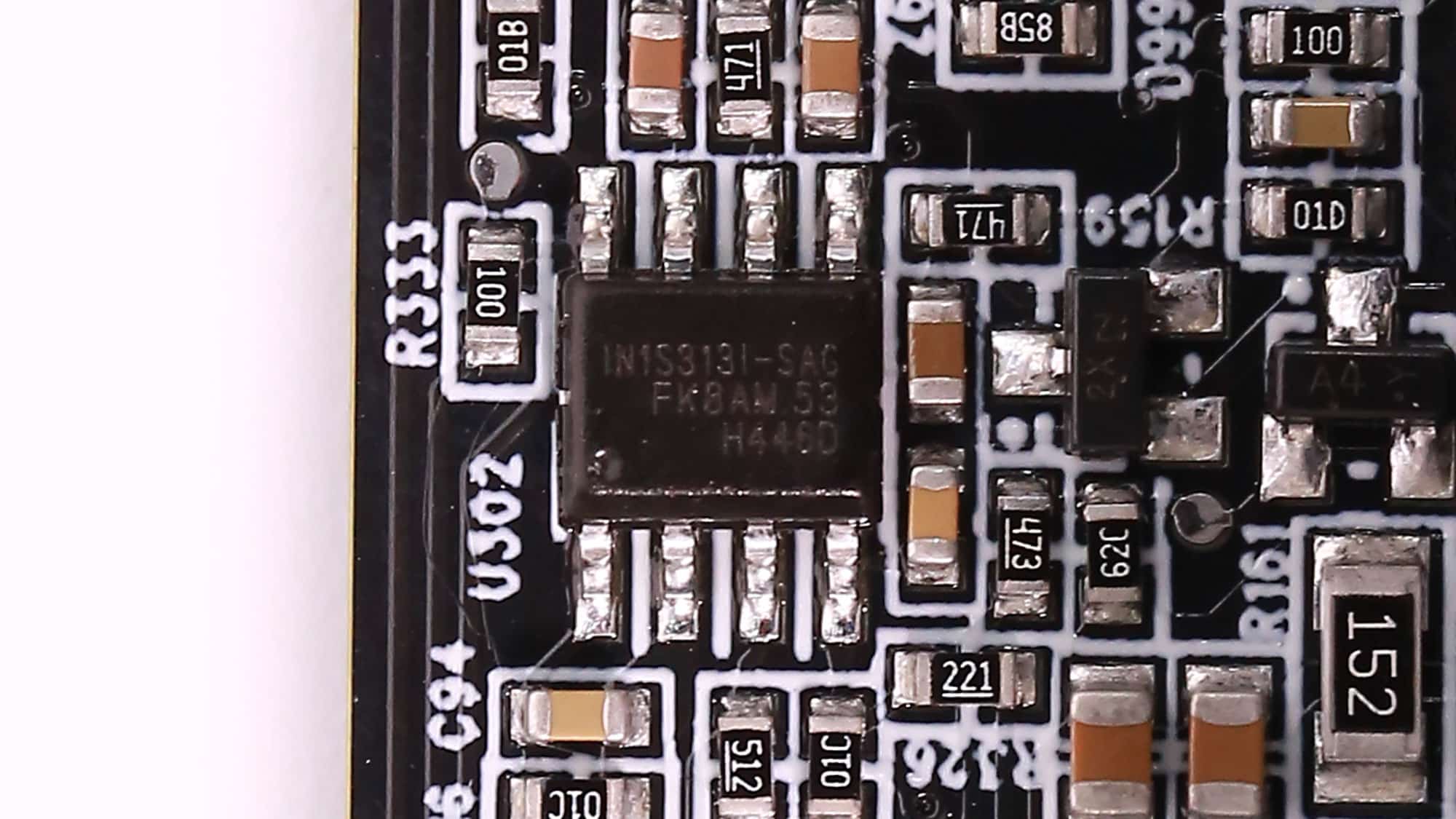

| Supervisor IC | IN1S3131-SAG |

| Fan Controller | OnSemi MJE172GA |

| Fan Model | Cooler Master Mobius 135 FA13525M12LAAB (135mm, 12V, 0.4A, Loop Dynamic Bearing Fan) |

| 5VSB | |

| Standby PWM Controller | On-Bright OB2365S |

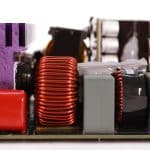

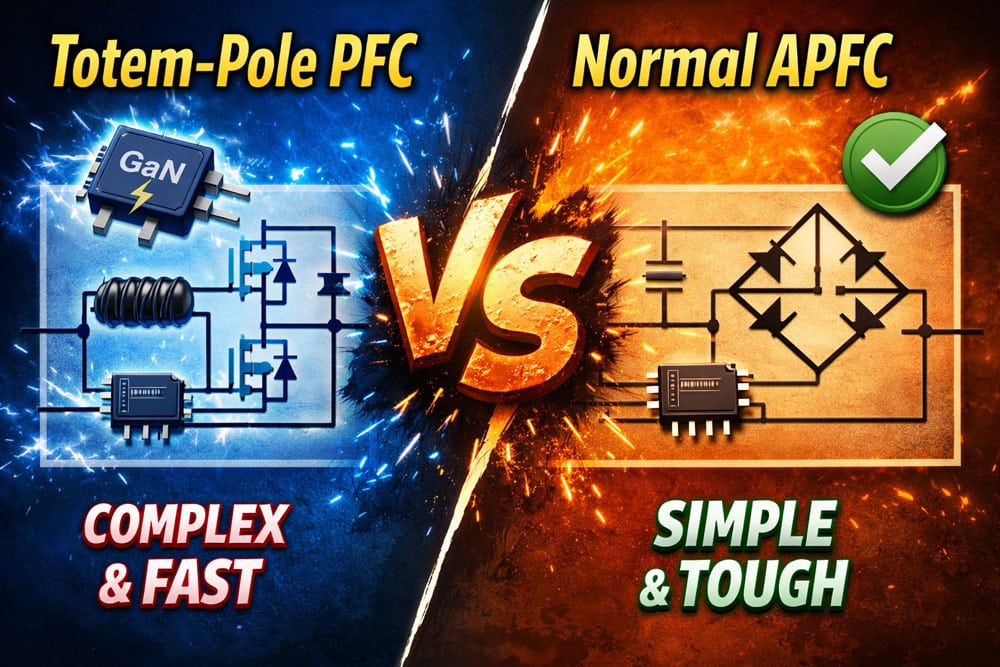

The modern design has an interleaved APFC converter and a half-bridge topology. Weirdly, such a powerful PSU doesn’t use a full-bridge topology. On the secondary side, we find the typical: a synchronous rectification scheme for 12V and a pair of DC-DC converters for the minor rails.

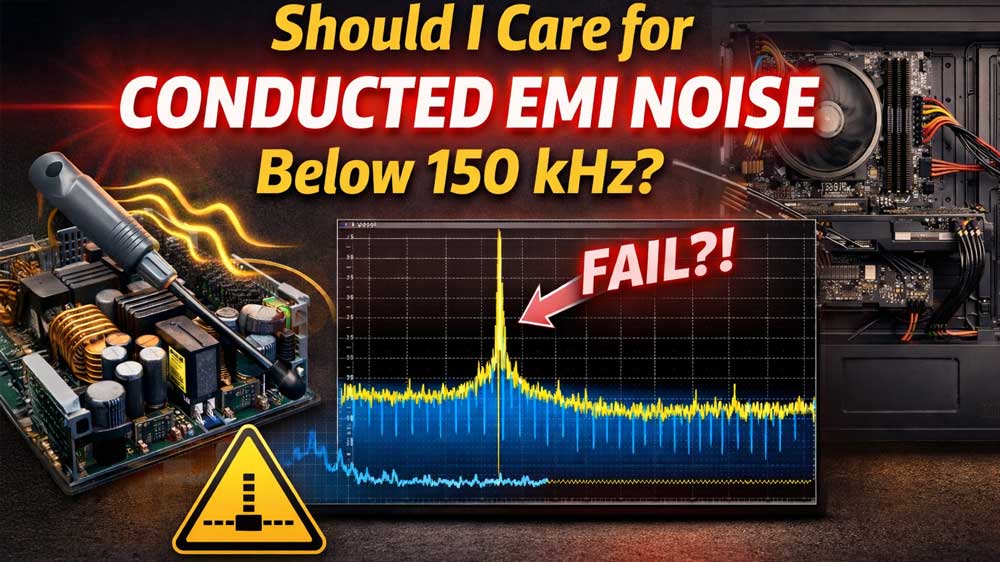

The transient filtering stage has all the necessary parts to block incoming and outgoing EMI emissions. Typically, it starts at the AC receptacle and continues on the main PCB.

The NTC thermistor’s resistance is high to restrict inrush currents. A bypass relay supports the NTC thermistor.

The two parallel bridge rectifiers are on the same heatsink. There is another one, probably handling the 5VSB rail, located between the APFC’s transformers.

An interleaved APFC converter is used, where two PFC circuits operate in parallel with a phase difference. This minimizes input and output current ripple and lowers conduction losses, increasing efficiency and doubling the effective switching frequency. The interleaved APFC converter uses two Infineon FETs and two Jilin Sind boost diodes. The bulk caps are by TK and offer a combined capacity of 1360uF. They are rated for 2,000 h at 105 °C.

The APFC controller is a Texas Instruments UCC28063 supported by a Champion CM03X.

The two Infineon IPW60R060P7 primary switching FETs are installed in a half-bridge topology, and an LLC resonant converter is used for higher efficiency. The driver ICs are a pair of Texas Instruments UCC27524.

The resonant controller is a Champion CU6901VAC.

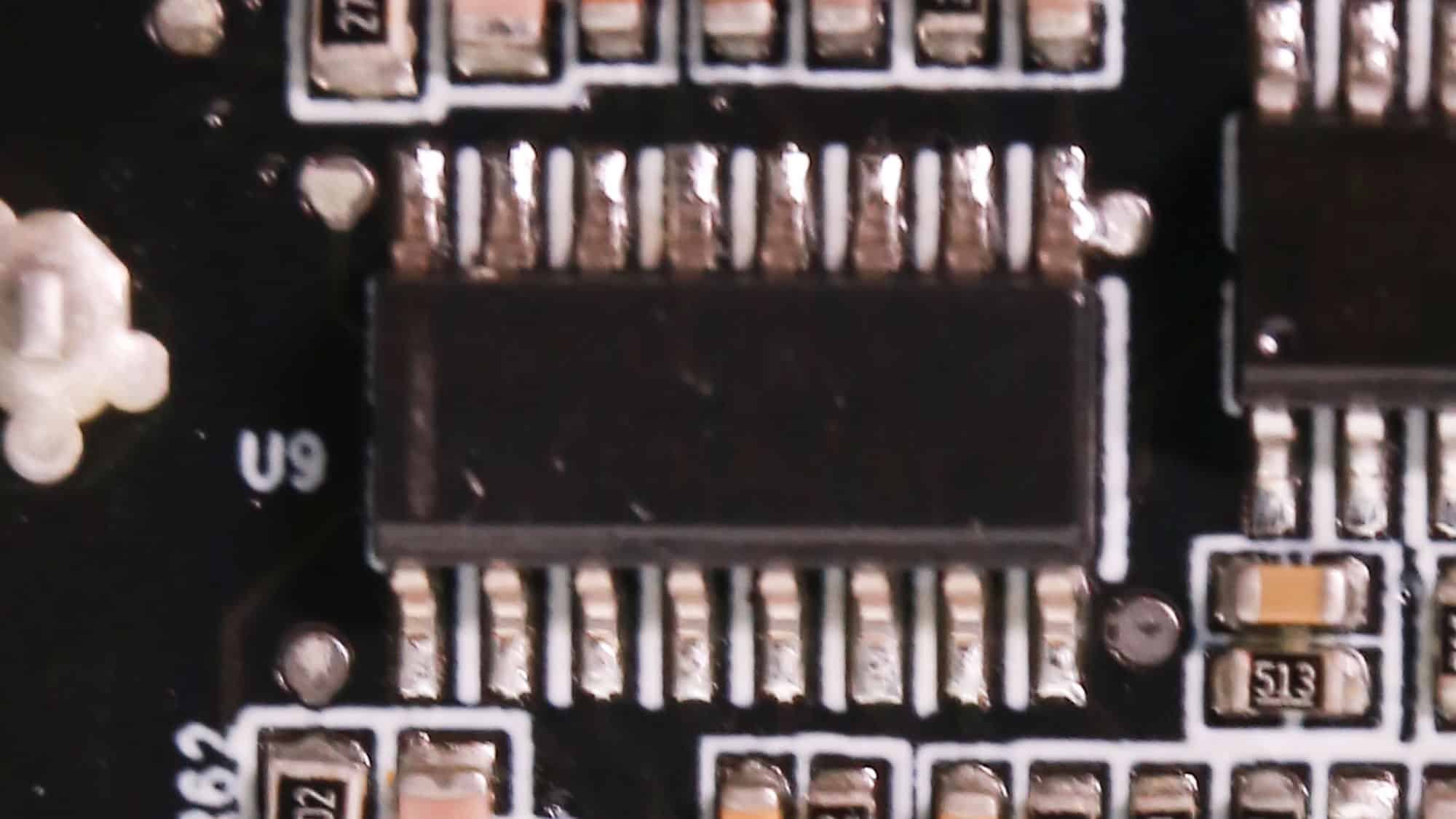

The PSU has an MCU (Arery AT32F421F6P7), which is mainly used for monitoring since analog controllers handle all primary circuits.

The main transformer has a pair of PCBs attached to restrict energy losses during power transfers. We had to destroy one of them to identify all the parts.

Twelve NCEPower NCEP40T15GU FETs regulate the 12V rail. They are installed on a PCB next to the main transformer to minimize energy losses due to power transfers over PCB traces or cables. This is a smart way to increase efficiency, but you must ensure that the 12V FETs have adequate cooling.

Two DC-DC converters generate the minor rails.

Rubycon provides the electrolytic filtering capacitors. FPCAP makes the polymer caps, and there are so many of them in this PSU!

You can find more information about capacitor performance and other specs below:

The supervisor controller is an IN1S3131-SAG.

The standby PWM controller is an On-Bright OB2365S

Many small electrolytic and polymer caps at the face of the modular panel form a ripple-filtering layer.

The soldering quality is good.

The cooling fan is a Mobius 135 FA13525M12LAAB with a loop dynamic bearing. This is a high-quality fan.

Great Info !!!!!!!

Please continue forever.

FPcaps is a brand , maker is Nichicon

thank you!

When can I see the review for FSP MEGA TI 1650W