Part Analysis

| General Data | |

| Manufacturer (OEM) | CWT |

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 6x Y caps, 2x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | NTC Thermistor SCK-0510 (5 Ohm @ 25°C) & Relay |

| Rectifier MOSFETs |

4x Toshiba TK055U60Z1 (600V, 40A @ 25°C, Rds(on): 0.055Ohm)

|

| APFC MOSFETs |

2x Infineon IPA60R099P7 (650V, 31A @ 25°C, Rds(on): 0.099Ohm)

|

| APFC Boost Diode |

Infineon IDH10G65C6 (650V, 10A @ 140°C)

|

| Bulk Cap(s) |

2x Nippon Chemic-Con (420V, 560uF each or 1120uF combined, 2000h @ 105°C, KMR)

|

| Main Switchers |

4x Alpha & Omega AOTF29S50 (600V, 29A @ 25°C, Rds(on): 0.15Ohm)

|

| APFC Controller | Champion CM6500UNX & Sync Power SPN5003 (reducing no-load consumption) |

| Resonant Controller |

Champion CM6901T2X

|

| IC Driver | 2x Novosense NSI6602BD |

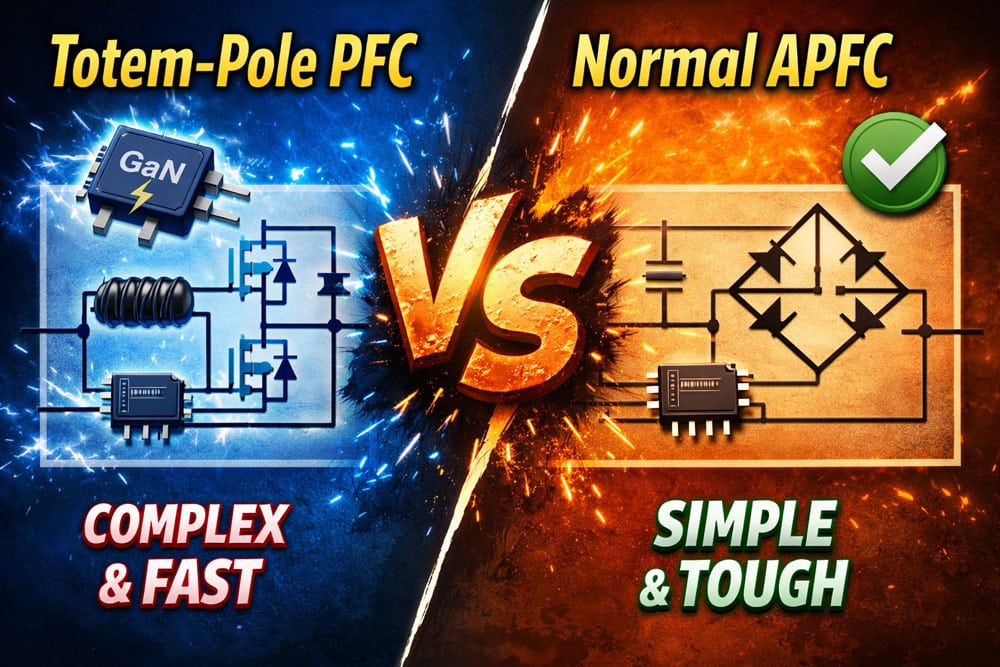

| Topology | Primary side: Bridgeless PFC, Full-Bridge & LLC Resonant Converter Secondary side: [12V] Synchronous Rectification & [Minor Rails] DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 6x Infineon BSC010N04LS (40V, 206A @ 100°C, Rds(on): 1.0mOhm) |

| 5V & 3.3V | DC-DC Converters: 4x UBIQ Semi QN3107M6N (30V, 70A @ 100°C, Rds(on): 2.6mOhm) PWM Controller(s): UPI-Semi uP3861P |

| Filtering Capacitors | Electrolytic: 6x Nichicon (2-5,000 @ 105°C, HD(M)) 3x Rubycon (4-10,000 @ 105°C, YXJ) Rubycon (3-6,000 @ 105°C, YXS) Rubycon (10,000 @ 105°C, YXM) Nichicon (4-10,000 @ 105°C, HE(M)) Polymer: 23x Nippon Chemi-Con, 19x FPCAP |

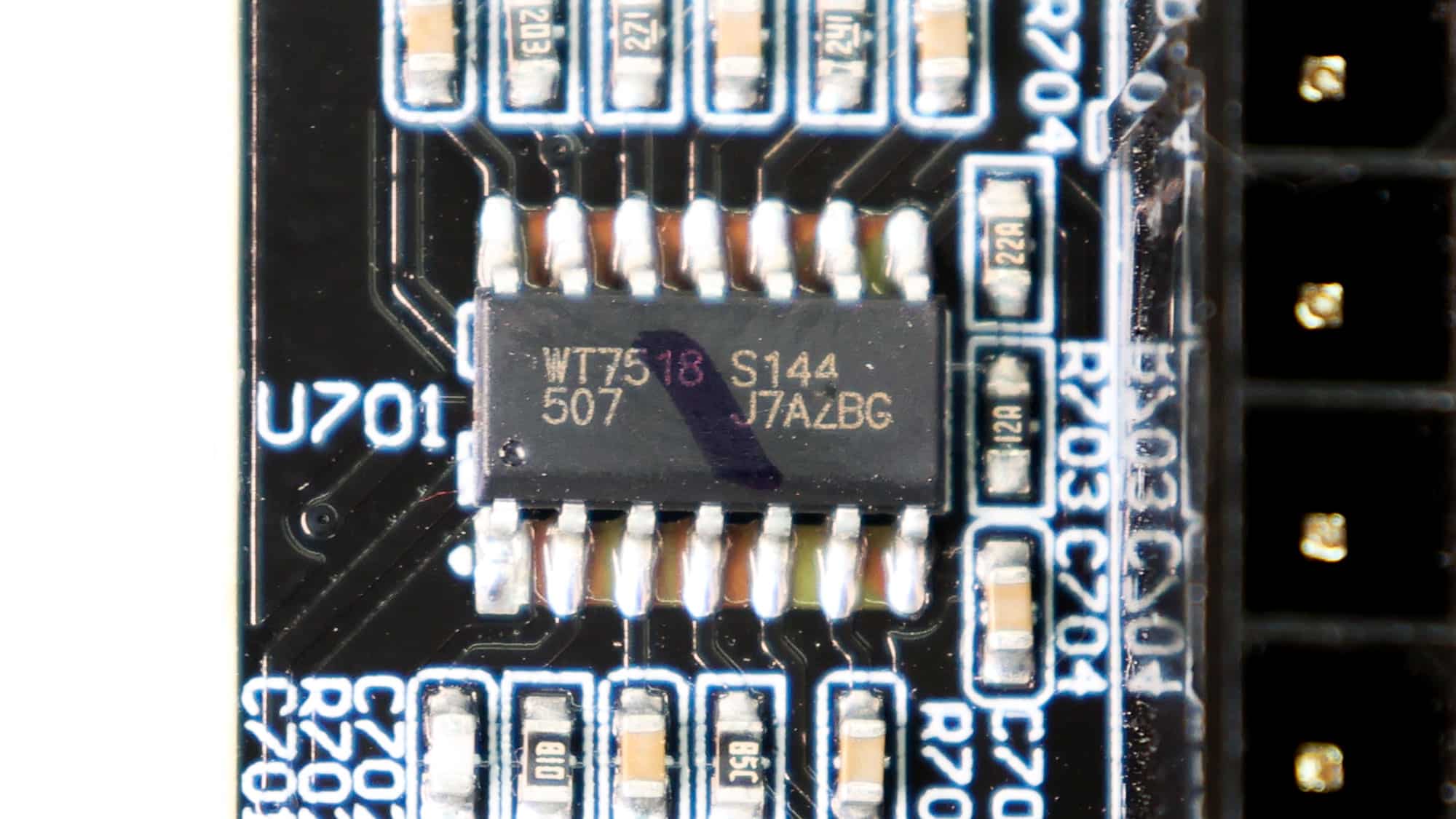

| Supervisor IC | Weltrend WT7518 (OVP, UVP, OCP, PG) |

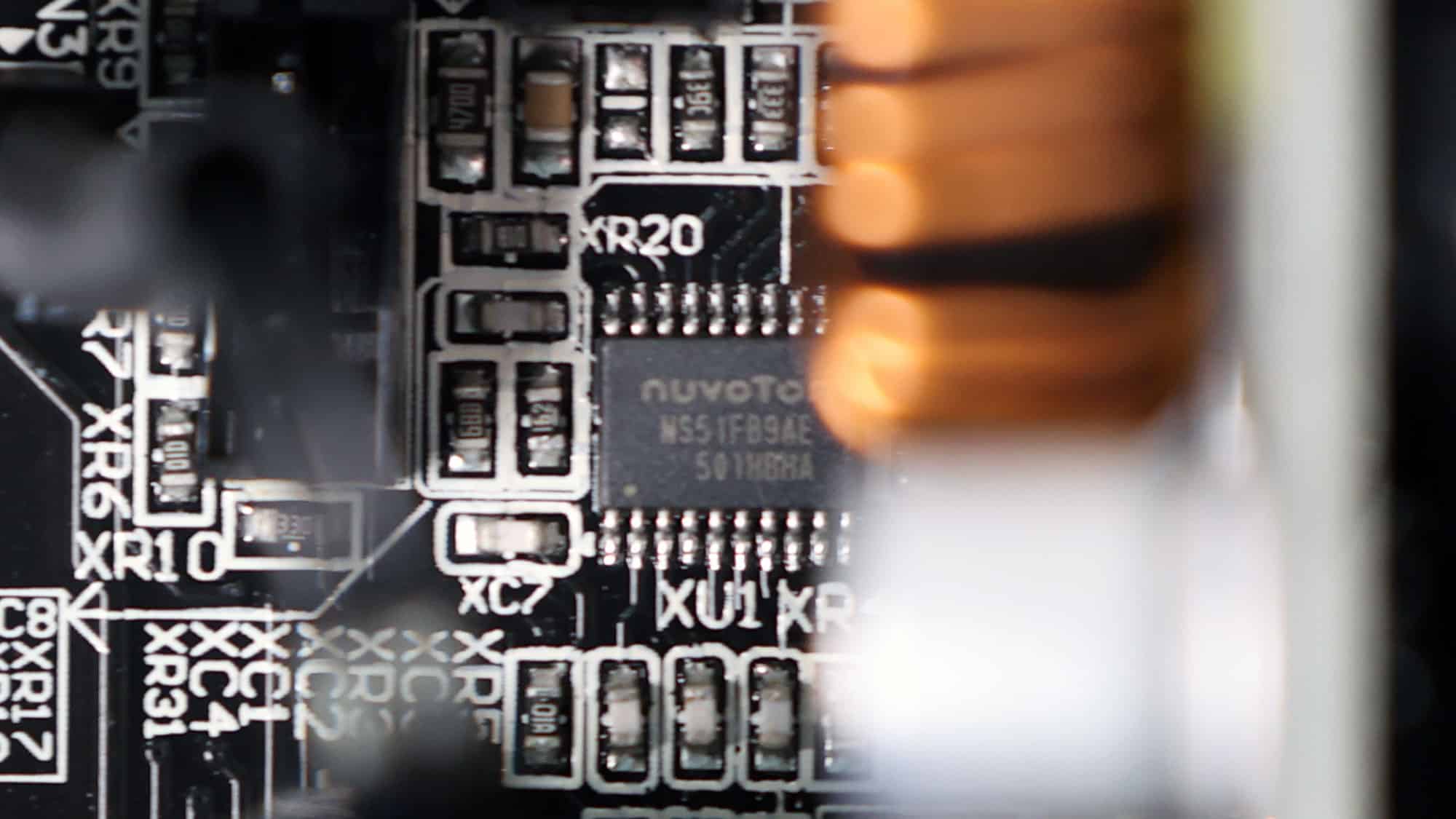

| MCU / Fan Controller | Nuvoton MS51FB9AE |

| Fan Model | BQ SIW4-13525-MF (135mm, 12V, 0.4A, Fluid Dynamic Bearing Fan) |

| 5VSB Circuit | |

| Rectifier (High Side) |

Dongke DK5V45R10V (45V, 10mOhm)

|

| Standby PWM Controller |

On-Bright OB2365T

|

CWT delivers this platform with a modern architecture that includes bridgeless APFC for reduced energy losses and a full-bridge topology to enhance power-handling capability. The primary side employs an LLC resonant converter to further improve efficiency. The PCB has standard (to large) dimensions and is arranged to keep noise output low. It isn’t overcrowded; instead, component spacing is generous, particularly on the secondary side, allowing for optimal airflow. Notably, the electrolytic capacitors are positioned well away from heat sources, which significantly extends their lifespan. In typical CWT fashion, the secondary-side heatsinks are modest in size, and the same applies to the primary side, where the largest heatsink serves the APFC stage.

All components come from reputable manufacturers, as cost is not a limiting factor for this flagship product line. Infineon FETs are among the best in the industry, offering top performance and exceptional reliability.

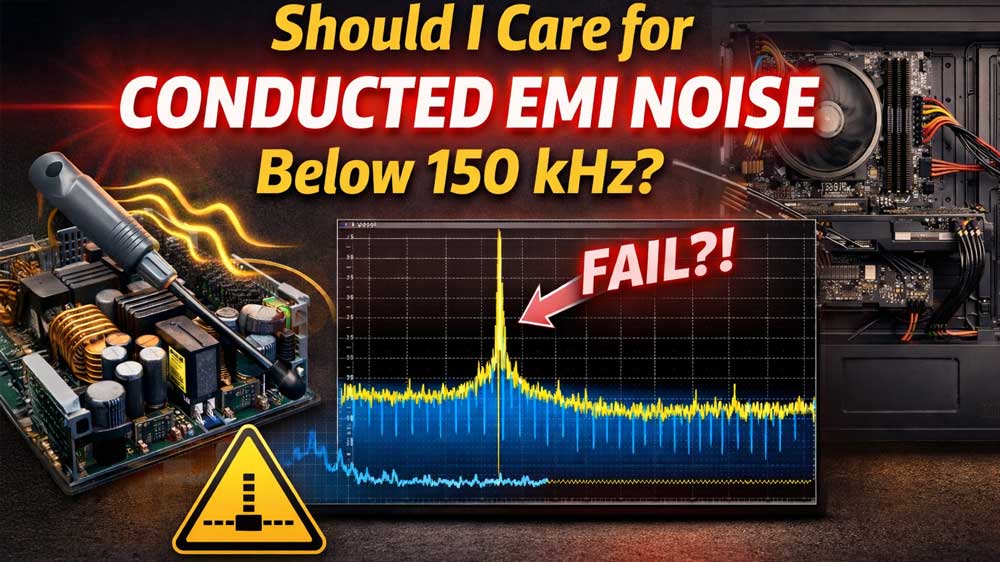

The transient filtering stage contains all the necessary components to block both incoming and outgoing EMI emissions. Typically, it starts at the AC receptacle and continues on the main PCB.

There is an MOV to protect from voltage surges and an NTC thermistor with a resistance of 5 ohms. Moreover, a bypass relay supports the NTC thermistor.

This platform doesn’t use bridge rectifiers to handle the incoming AC signal; instead, it uses four Toshiba TK055U60Z1 FETs, which have notably lower losses than the diodes used in bridge rectifiers. This is an effective but expensive way to minimize energy losses at the PSU’s primary side. It is typically used in Titanium efficiency platforms to minimize energy losses.

The APFC converter uses two Infineon IPA60R099P7 FETs (three in the 1200W model) and a single Infineon IDH10G65C6 boost diode. Chemi-Con manufactures the bulk capacitors. Their combined capacity is 1120 μF, and both are rated for 2,000 hours at 105 °C. The voltage rating is 420V, providing a large enough margin from the APFC’s DC bus voltage (approximately 380-400V DC).

The APFC controller is a Champion CM6500UNX. The Sync Power SPN5003 supports it to reduce vampire power.

Four Alpha & Omega AOTF29S50 primary-switching FETs are used in a full-bridge topology (the same as in the 1200W model), and an LLC resonant converter is employed for enhanced efficiency.

The LLC resonant controller is a Champion CM6901T2X.

The PSU’s main transformer. One of its main functions is to electrically isolate the primary and secondary sides.

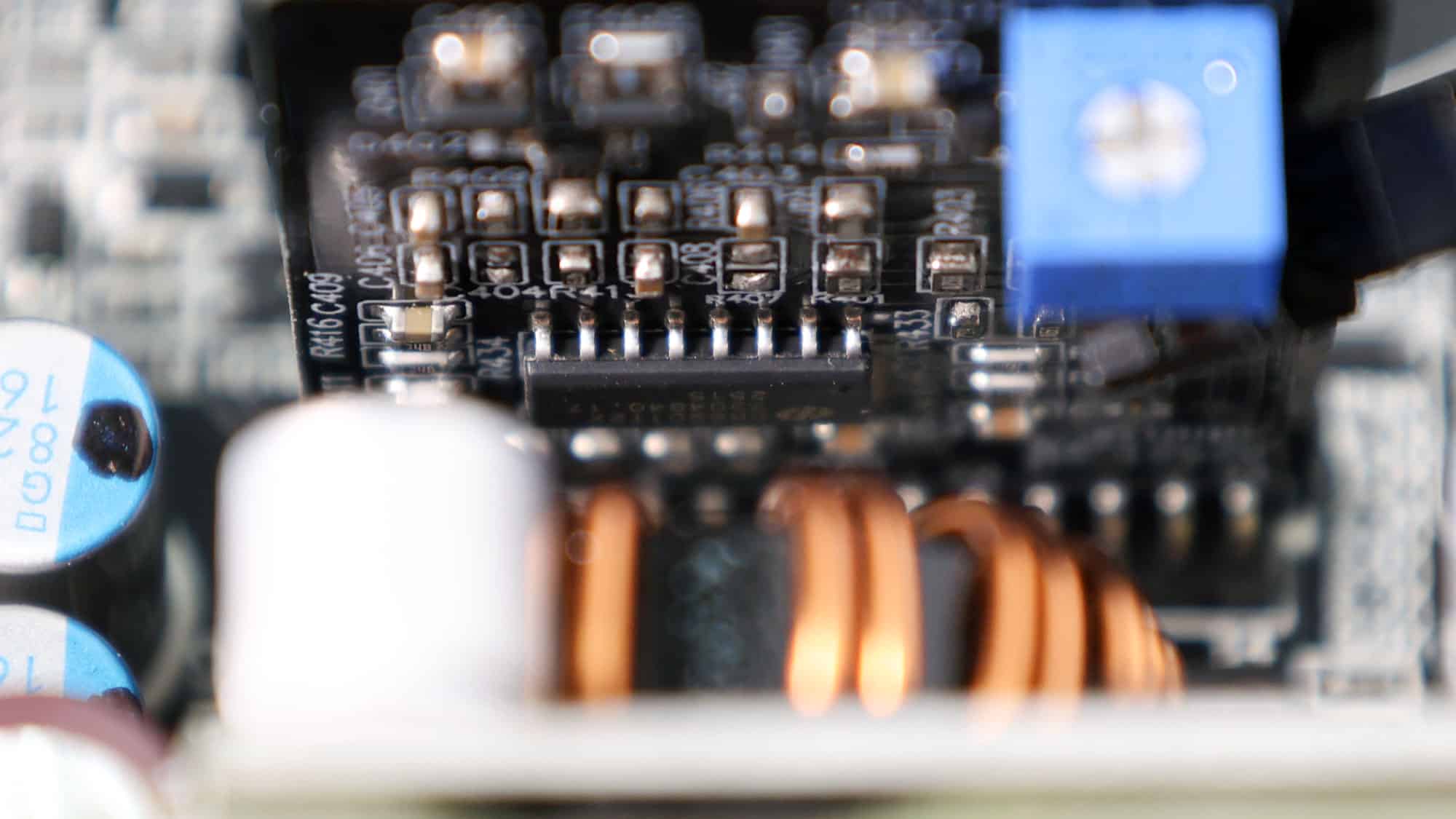

Six Infineon BSC010N04LS FETs regulate the 12V rail. They are installed on the business (top) side of the PCB, and two small heatsinks handle their cooling.

Two DC-DC converters generate the minor rails. They use four UBIQ Semi QN3107M6N FETs. The PWM controller is a UPI-Semi uP3861P.

Rubycon and Nichicon provide the electrolytic capacitors. FPCAP and Chemi-Con make the polymer capacitors.

You can find more information about capacitor performance and other specs below:

The standby PWM controller is an On-Bright OB2365T.

Many polymers and a large electrolytic capacitor on the modular panel’s face form an additional ripple-filtering layer.

The supervisor IC is a Weltrend WT7518 (OVP, UVP, OCP, PG). It is installed on the modular board.

The fan controller is a Nuvoton MS51FB9AE.

Soldering quality is good in most areas. The area under the 12V FETs is the “worst”- looking, but it will in no way affect the unit’s performance or reliability.

The cooling fan is a BQ SIW4-13525-MF that uses a fluid-dynamic bearing. This is a high-quality fan!

Thanks for the review, only the 850W has left. Would you say that the Pure Power 13 M is a better choice? Dark Power 14 does not seem to be as much better as the price increase would suggest.

Aris, when you ill add the certification of husky 1200w on database?!

We have them in the pipeline but we also have around 40x samples in front of it so it will take some time