Part Analysis

| General Data | |

| Manufacturer (OEM) | Great Wall |

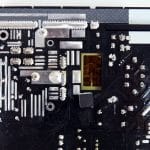

| PCB Type | Double-Sided |

| Primary Side | |

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | 1x NTC Thermistor SCK205 (5Ohm @ 25°C) & Relay |

| Bridge Rectifier(s) |

2x Vishay GBUE2560 (600V , 25A @ 140°C)

|

| APFC MODFETs |

1x Transphorm TP65H035G4WS (650V, 29.5A @ 100°C, Rds(on): 0.41Ohm)

|

| APFC Boost Diode |

1x CREE C3D16065 (650V, 16A @ 142°C)

|

| Bulk Cap(s) | |

| Main Switchers |

2x Rohm Semiconductor R6055VNZ4 (600V, 55A @ 25°C, Rds(on): 0.08Ohm)

|

| APFC Controller | |

| Resonant Controller |

1x Champion CM6901X

|

| IC DRIVER |

1x Novosense NSi6602

|

| Topology |

Primary side: APFC, Half-Bridge & LLC converter

Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

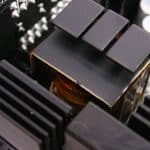

| +12V MOSFETs | 6x Infineon BSC014N04LS (40V, 100A @ 100°C, Rds(on): 1.4mOhm) |

| 5V & 3.3V | DC-DC Converters: 4x GP4A24 PWM Controller(s): 1x ANPEC APW7159C |

| Filtering Capacitors | Electrolytic: 1x Rubycon (4-10,000 @ 105°C, YXJ), 1x Rubycon (3-6,000 @ 105°C, YXT), 1x Rubycon (3-6,000 @ 105°C, YXG), 1x Rubycon (2-10,000 @ 105°C, YXF), 4x Nichicon (6-10000 @ 105°C, HW), Polymer: 35x FPCAP , 7x Nippon Chemi-Con |

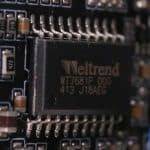

| Supervisor IC | Weltrend WT7881P |

| Fan Controller | AS358M |

| Fan Model | Everflow F1214025BL (135mm, 12V, 0.2A , Double Ball Bearing Fan) |

| 5VSB Circuit | |

| High Side Rectifier |

1x ER2J (600V, 2A @ 100°C)

|

| Standby PWM Controller | Power Integrations TNY278PN |

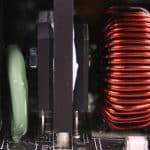

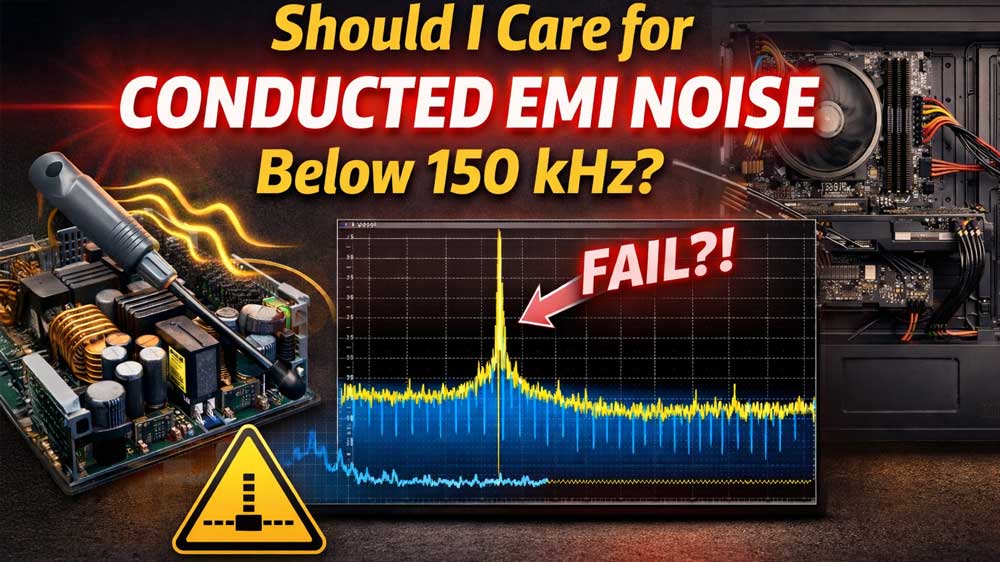

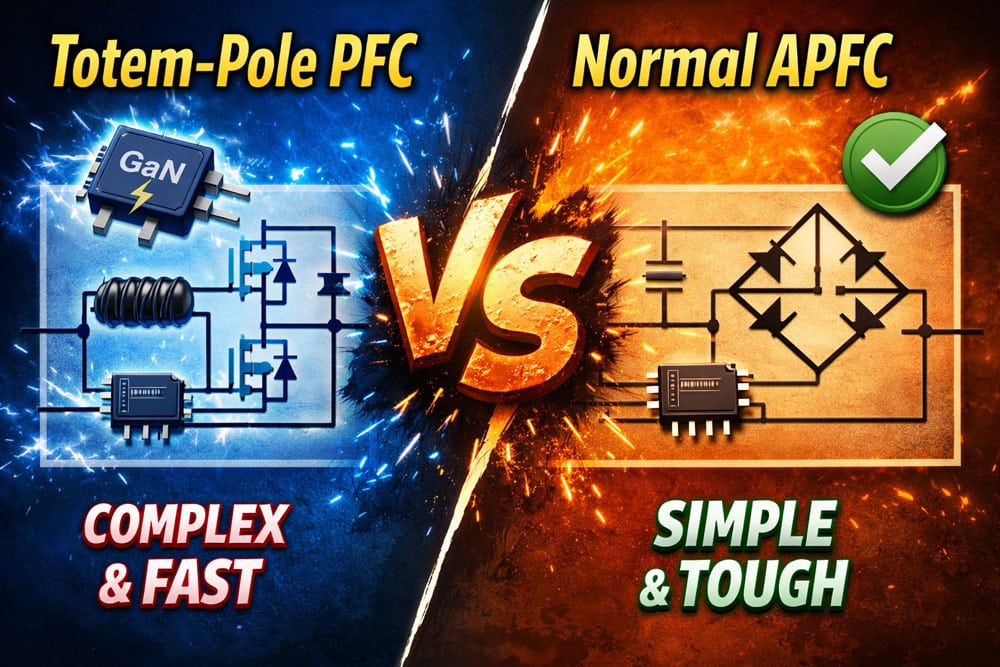

Like the 1000W model, the design is clean, with lots of clear space on the secondary side for unobstructed airflow. The primary side heatsinks are large, helping lower the fan’s speed and noise output. The only daughterboard holds the DC-DC converters that generate the minor rails. The design might be clean, but unfortunately, it is not as modern as I expected, given the MODFETs on the APFC converter. For starters, Great Wall didn’t use a bridgeless totem-pole APFC converter, which offers minimized energy losses and the highest possible efficiency, but a plain CCM one. Given the standard PFC controller, I believe that using MODFETs in this PSU helps more in marketing than in real-life performance.

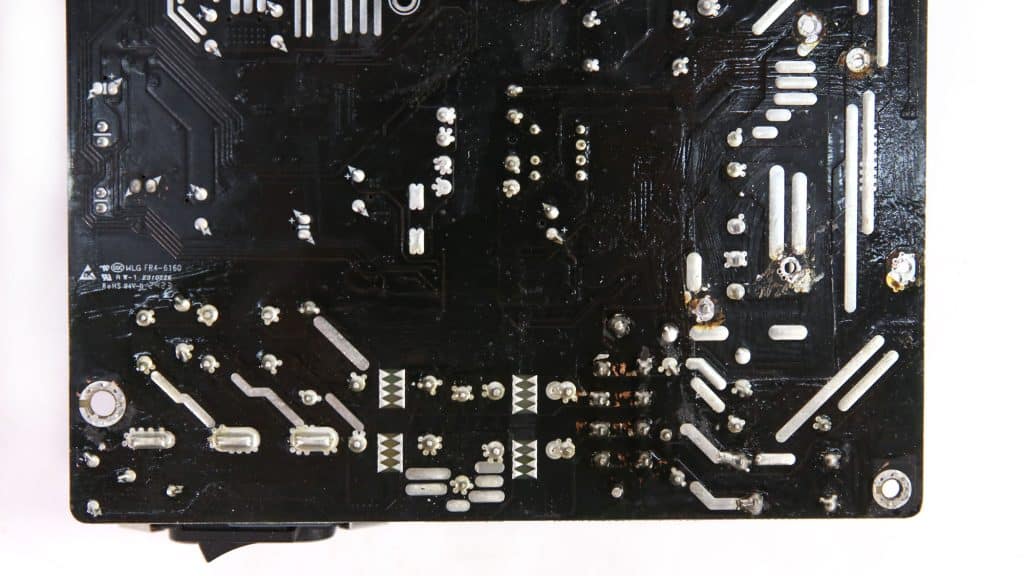

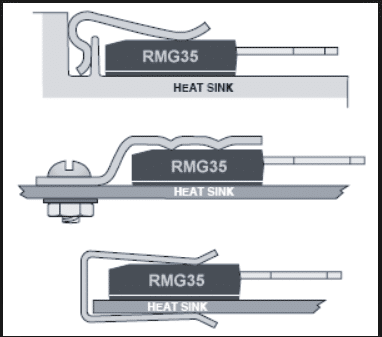

GW used quality parts everywhere, but I noticed some nasty marks on the PCB’s backside, which have no place in a high-end PSU. They won’t affect performance, most likely, but given GW’s high-end production lines, they shouldn’t be there in the first place. That said, it is good to see proper thermal pads used in the PSU’s FETs and a special heatsink along with thermal paste for the MODFETs, but if they wanted to do a perfect job, they should avoid using plain screws but ones with clips.

On the primary side, in addition to the typical APFC converter, we find a half-bridge topology and an LLC resonant converter. A synchronous rectification scheme on the secondary regulates the 12V rail, though six Infineon FETs and two DC-DC controllers handle the minor rails. All filtering caps are by well-known brands, and GW used several electrolytic caps to provide enough capacity for the PSU to withstand transient loads.

The cooling fan uses a double ball bearing, which is much more tolerant to high operating temperatures but also has increased bearing noise at low RPMs. Fluid dynamic bearings do not face this issue while providing an equally long lifetime under normal operating conditions. Given that a PSU fan most likely won’t have to operate under harsh conditions and because of the DBB-bearing noise, FDB fans dominate the PSU market.

@crmaris, what do you think of ASUS ROG Strix 1200W Gold Aura Edition? Is it worse than this one?

Why Asus says on their Website only PCIE 5.0 ready? Is there something missing?

Marketing didn’t get the memo 🙂

This one states PCIe 5.0 compliant, and on Nvidia’s website 5090 requires PCIe 5.1 compliance.

Will this PSU still be good for 5090?

it will be ok yes.

So Asus is going to release a rev. 2 of this PSU with updated fan?

Or you just going to be lucky to get one with better fan?

This is so sluggish of Asus.

I was really hoping this PSU would be the one I would buy, instead of the FSP hydro ti pro 1000w.

They installed new fans, after we found this issue.

actually this unit has the improved fan.

So with the new fan, do you recommend this over the FSP hydro ti pro 1000w in terms of pure silence?

Nope

I read that ball bearing fans become significantly louder over their lifespan, so they’re deceptive in terms of noise. Is that true? Also, I read that if they’re dropped they can be ruined, so they’re more delicate than FDB fans. It seems like a no-brainer to exclusively use FDB fans in high-end PSUs. Ball bearing fans appear to be able to produce more static pressure than other fan types but since FDB fans apparently can be used in low-noise PSUs, it seems that that advantage isn’t enough to outweight the drawbacks.

With not high quality DBB fans yes this can be the case.