In a landmark achievement with profound implications for the future of transportation and energy, a research team from the Korea Institute of Science and Technology (KIST) has successfully built a fully functional electric motor using cables made entirely of carbon nanotubes (CNTs), completely replacing copper. This isn’t just a laboratory curiosity; it is a tangible step toward a lighter, more efficient, and potentially more sustainable technological future.

The Core Breakthrough: Not Just Replacing, But Improving

The team, led by Dr. Ki-Hyun Ryu, didn’t just swap copper for carbon. They developed a sophisticated process to overcome the key weaknesses of previous CNT wires.

- The LAST Process: The “Lyotropic Liquid Crystal-Assisted Surface Texturing” process is the secret. It acts like a deep-clean and organizational system for the nanotubes. It removes residual metal catalyst particles that impede electron flow while perfectly aligning the CNTs, allowing them to conduct electricity more efficiently as a collective.

- The Resulting Cable: The Core-Sheath Composite Electric Cable (CSCEC) bundles these highly conductive, aligned CNT wires into a core, which is then wrapped in a flexible polymer insulator. This creates a lightweight, durable, and efficient replacement for traditional metal wiring.

The Tangible Difference: What This Enables

1. Drastic Weight Reduction for Increased Efficiency

This is the most immediate and impactful difference. The density of the CNT wire is 1.7 g/cm³, compared to copper’s 8.9 g/cm³, an 80% reduction in weight.

- Impact: In sectors like aerospace and electric vehicles (EVs), weight is the enemy of efficiency. Lighter wiring harnesses require less energy for movement, directly translating into a more extended range for EVs and reduced fuel consumption for aircraft. Every gram saved minimizes the carbon footprint during operation.

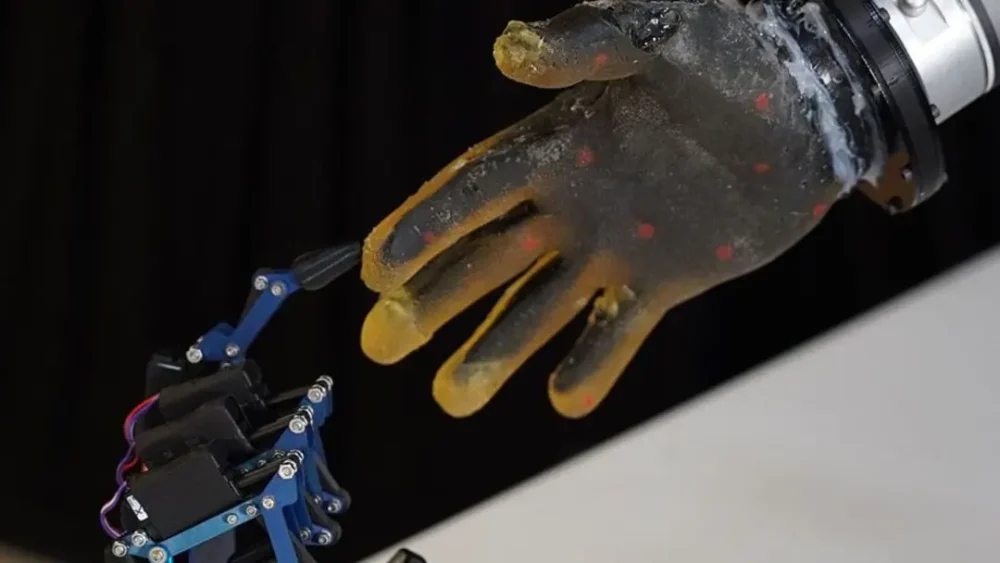

2. A Viable Path to “Metal-Free” Machinery

The team proved the concept’s viability by powering a scale model car exclusively with their CNT-based motor. While the current model car moved at 0.52 m/s, the achievement is foundational.

- Impact: This demonstrates that complex electromechanical systems can, in principle, operate without metallic conductors. It opens the door to entirely new design philosophies for engineers, where the weight and corrosion limitations of metal are no longer a primary constraint.

3. Competitive Performance-by-Weight, Not Just Raw Power

While the CNT motor’s rotational speed (3,420 RPM at 3V) is currently lower than a copper equivalent (18,120 RPM), the story changes when you consider mass. The specific rotational velocity (RPM per milligram of conductor) is nearly identical—43.4 RPM/mg for CNT vs. 47.8 RPM/mg for copper.

- Impact: This means that for the same weight, you can get similar performance. Or, for the same performance, you can achieve massive weight savings. This “punching above its weight” makes CNT cables a compelling alternative where mass is a critical factor.

4. A Foundation for a More Sustainable Manufacturing Cycle

The production of copper is energy-intensive and a significant source of CO2 emissions. While CNT synthesis has its own environmental cost, the research points to a promising circular economy.

- Impact: Recent studies show that CNT sheets can be recycled and re-spun with minimal loss of properties. This potential for a closed-loop system, combined with the operational emissions savings from lighter vehicles, positions CNT conductors as a key player in long-term green technology strategies.

From Laboratory to Reality

The research is clear that this is a beginning, not an end. The electrical conductivity of the CNT cables, while significantly improved, is still about one-seventh that of copper. The challenges of scaling production, ensuring long-term durability under real-world conditions, and integrating with existing infrastructure remain.

However, the KIST team has provided a definitive answer to a critical question: Yes, it is possible to build a practical, metal-free motor that leverages the unique advantages of carbon nanotubes to create a lighter, more efficient future. This breakthrough lays the foundation for a world where our wires are no longer made of metal but of precisely engineered carbon.