A research team from the Max Planck Institute for Polymer Research has achieved a major milestone in the development of stretchable electronics, unveiling a modified conductive polymer tailored for next-generation wearable biosensors. Their new approach enhances both the flexibility and electrical conductivity of PEDOT: PSS, a well-known conductive polymer, making it more suitable for on-skin sensors that can monitor health biomarkers like stress hormones in sweat.

The study was recently published in Advanced Science and offers fresh insight into how materials can be engineered for the growing field of skin-like, biocompatible electronics.

The Challenge: Stretchability vs. Conductivity

Wearable biosensors require a delicate balance of properties: they must be soft and stretchable like skin, biocompatible for long-term contact, and electrically conductive to transmit signals effectively. While PEDOT: PSS has long been used in flexible electronics for its transparency and biocompatibility, it suffers from limited stretchability, making it less than ideal for wearables that conform to moving body parts.

The Innovation: Transfer-Printing With Embedded Plasticizers

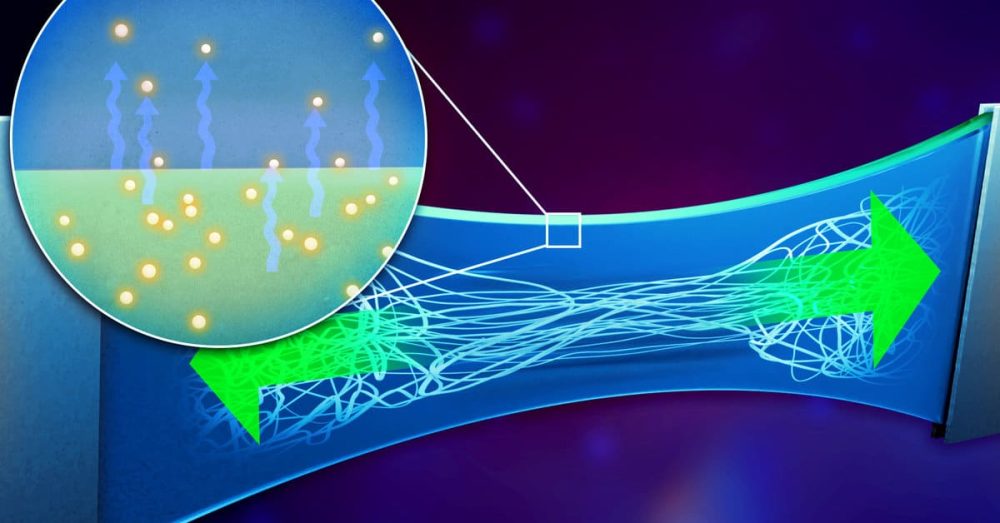

Led by Dr. Ulrike Kraft, the research team developed a transfer-printing technique that allows PEDOT: PSS films to be printed onto stretchable, biodegradable substrates. During the process, plasticizers from the substrate diffuse into the polymer layer, drastically improving both its mechanical elasticity and electrical performance.

“The plasticizers contained in the substrates diffuse into the conductive polymer, thereby improving both the electrical performance and the mechanical properties,” explains Carla Volkert, the study’s first author.

What Happens At The Molecular Level

To understand why this works, the researchers used a mix of microscopy, spectroscopy, and electrical tests. They discovered that polymer chain alignment occurs under strain, enhancing electrical conductivity precisely when the material is being stretched. This behavior is ideal for wearable sensors that experience constant movement.

Such insights provide fundamental understanding of how soft electronic materials behave under real-world conditions, something that has remained a significant challenge in the field.

Toward Real Biosensors For Sweat and Stress

The enhanced PEDOT: PSS film could enable a new generation of wearable devices, from flexible ECG patches to sweat-analyzing sensors that track cortisol levels for real-time stress monitoring.

“Our method simultaneously improves the stretchability and electrical conductivity of PEDOT: PSS, an important step toward on-skin biosensors,” says Dr. Kraft.

The team is now focused on building actual biosensors using their modified polymer and testing their performance in real-world scenarios.

The Future

This research not only solves a key material bottleneck in wearable electronics but also points toward a future of personalized, real-time health monitoring using soft, stretchable patches that feel like a second skin. By overcoming the tradeoff between conductivity and elasticity, the Max Planck team has laid critical groundwork for making high-performance biosensors a mainstream reality.