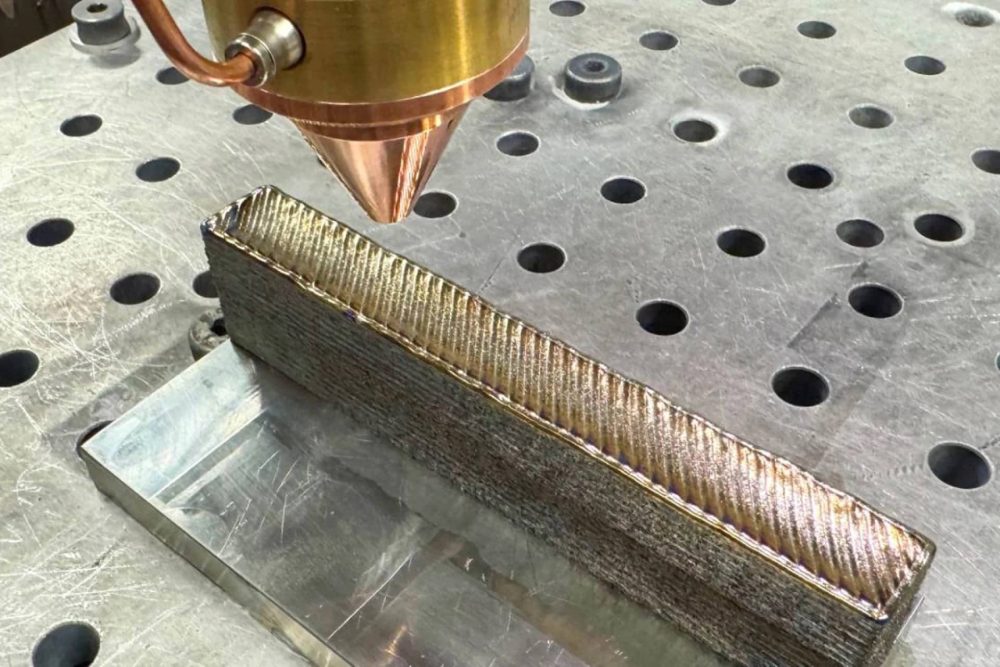

Engineers at RMIT University have unveiled a revolutionary 3D-printed titanium alloy that outperforms standard alloys in strength, durability, and cost. Developed using a novel alloy design framework, the new material is 29% cheaper to produce than the widely used Ti-6Al-4V alloy, and it’s even stronger and more ductile, thanks to a uniform grain structure that eliminates a major flaw in traditional 3D-printed titanium.

Published in Nature Communications, the research outlines a time- and cost-saving method to predict and control the grain structure of metal alloys during additive manufacturing. By replacing expensive vanadium with more affordable, readily available materials, the RMIT team has addressed two critical barriers to widespread adoption of 3D-printed titanium: high costs and inconsistent mechanical properties.

“3D printing allows faster, less wasteful, and more customizable production, yet we’re still relying on legacy alloys like Ti-6Al-4V,” said Ryan Brooke, PhD candidate at RMIT’s Centre for Additive Manufacturing (RCAM) and lead author of the study. “It’s like we’ve built a jet but are still just driving it down the street.”

Ti-6Al-4V, or Grade 5 Titanium, has long been the go-to alloy in aerospace, biomedical, and automotive industries. However, its 3D-printed form tends to exhibit columnar grain structures that weaken parts in certain directions. The new alloy developed by RMIT avoids this flaw by promoting a more even, equiaxed grain structure, resulting in better performance and greater design reliability.

Predicting Strength Through Science

The research team identified a new predictive method based on three key metallurgical parameters:

- Non-equilibrium solidification range (ΔTs)

- Growth restriction factor (Q)

- Constitutional supercooling parameter (P)

Among them, the constitutional supercooling parameter (P) emerged as the most reliable metric for selecting alloying elements and predicting grain structure outcomes in 3D-printed metals.

“This framework accelerates alloy development, slashing time and costs by reducing trial-and-error cycles,” Brooke added. “It’s a full leap forward, not just an incremental improvement.”

Although the exact composition of the new alloy remains proprietary due to commercial plans, the research validates the approach for creating stronger, cheaper, and more reliable titanium alloys tailored for additive manufacturing.

Commercialization in Sight

Having filed a provisional patent, the RMIT team is now seeking industry partners to help bring the new alloy to market, with potential applications in:

- Aerospace structures

- Jet engine components

- Medical implants (e.g., hip and knee replacements, dental devices)

- Automotive and maritime parts

- Sporting goods and consumer devices

“We are very excited about the prospects of this new alloy, but it requires a full ecosystem to succeed,” said Professor Mark Easton, corresponding author of the study. “We welcome industry collaborations across the supply chain.”

This innovation follows three years of research, experimental validation, and market consultation, including feedback from aerospace, MedTech, and automotive sectors via CSIRO’s ON Prime program.

As the world moves toward faster, more sustainable, and more affordable production of high-performance parts, RMIT’s breakthrough may mark a turning point in how we use 3D printing to shape the future of manufacturing.