Lithium-ion batteries (LiBs) are the go-to power source for many of our everyday devices. However, researchers and material scientists have been looking for ways to improve their performance without making them more expensive.

Traditionally, graphite has been the primary material for LiB anodes (the part of the battery that stores and releases energy). It’s affordable, lightweight, and durable. However, new studies have shown that alloy-based anodes—made from metals like silicon, tin, or aluminum—could offer even better performance and cost savings.

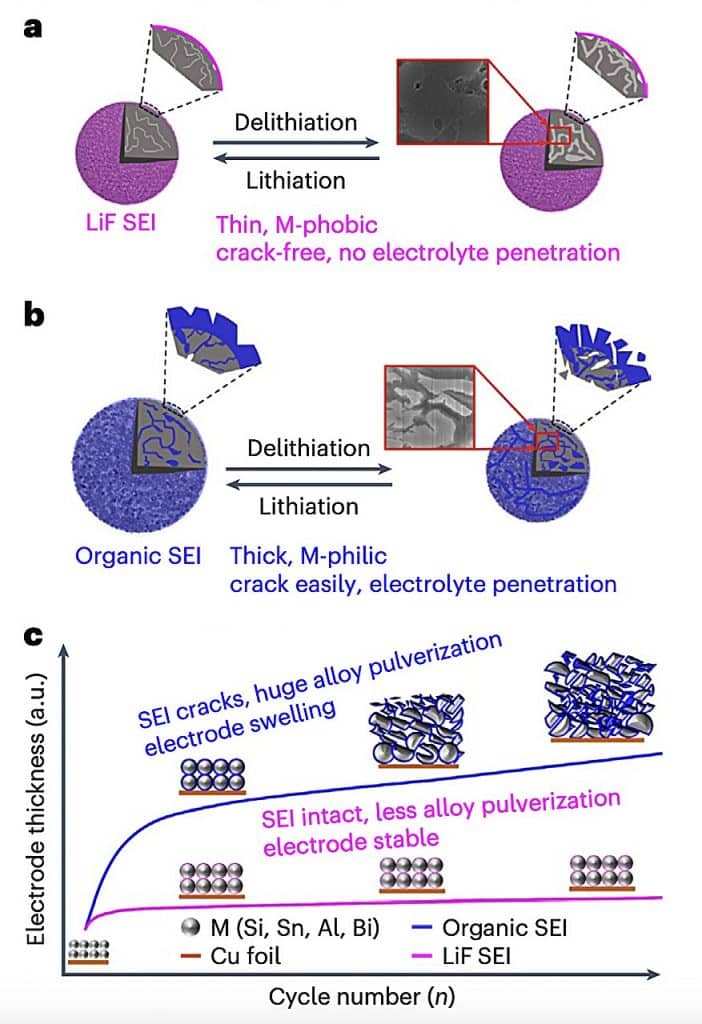

Despite this potential, these alloy-based anodes have needed help with reliability. One big issue is that they can degrade quickly and have lower efficiency when used with common battery electrolytes. This is due to a breakdown in the protective layer on the anode, which leads to cracks and further degradation of the battery over time. A recent University of Maryland and Rhode Island study could change that. The researchers have developed a new asymmetric electrolyte design that allows alloy-based anodes to perform much better. Their electrolyte forms a more robust protective layer on the anode, which leads to significantly longer battery life and higher capacity retention.

When tested, the new design showed impressive results, maintaining over 85% of its capacity after 400 cycles—more than twice the performance of many current batteries. This breakthrough could pave the way for longer-lasting, more efficient batteries.

Based on NMEP, the new electrolyte is designed to work well with high-capacity anodes and cathodes. This innovative design could be tested in a broader range of batteries in the coming years, potentially leading to significant advancements in next-generation energy storage.

Source:Techxplore.com