Researchers at Oregon State University (OSU) have developed an innovative 3D printing technique for creating shape-changing materials that mimic muscle movement. These materials, known as liquid crystalline elastomers (LCEs), promise significant advancements in robotics, biomedical devices, and energy systems. Devin Roach of the OSU College of Engineering led the findings, which were published in the journal Advanced Materials.

What Are Liquid Crystalline Elastomers?

LCEs are soft, flexible polymers that can dramatically alter their shape when exposed to stimuli such as heat. They function as “soft motors,” offering unique advantages over traditional rigid motors, especially in applications involving soft or delicate environments.

“Since LCEs are soft, they integrate seamlessly with the human body,” explains Roach, an assistant professor of mechanical engineering. “They could be used for targeted drug delivery, stents for medical procedures, or urethral implants to address incontinence.”

In addition to their medical applications, LCEs can convert thermal energy—such as solar or electrical—into mechanical energy. This makes them ideal for energy storage and usage on demand.

Applications Beyond Medicine

LCEs also hold significant potential in robotics and aerospace:

- Soft robotics: Robots using LCEs could safely operate in hazardous or inaccessible environments.

- Aerospace systems could act as actuators for automated tasks such as radar deployment, deep-space grappling, or extraterrestrial exploration.

Their effectiveness comes from a unique combination of properties:

- Anisotropy: The material’s directional strength is similar to wood grain’s.

- Viscoelasticity: A blend of elasticity (like rubber) and viscosity (like honey), enabling gradual deformation and recovery.

The Key Innovation: Molecular Alignment

A significant challenge in using LCEs has been aligning their molecules to unlock their shape-changing abilities. Roach and collaborators from Harvard University, the University of Colorado, and national laboratories such as Sandia and Lawrence Livermore discovered a solution.

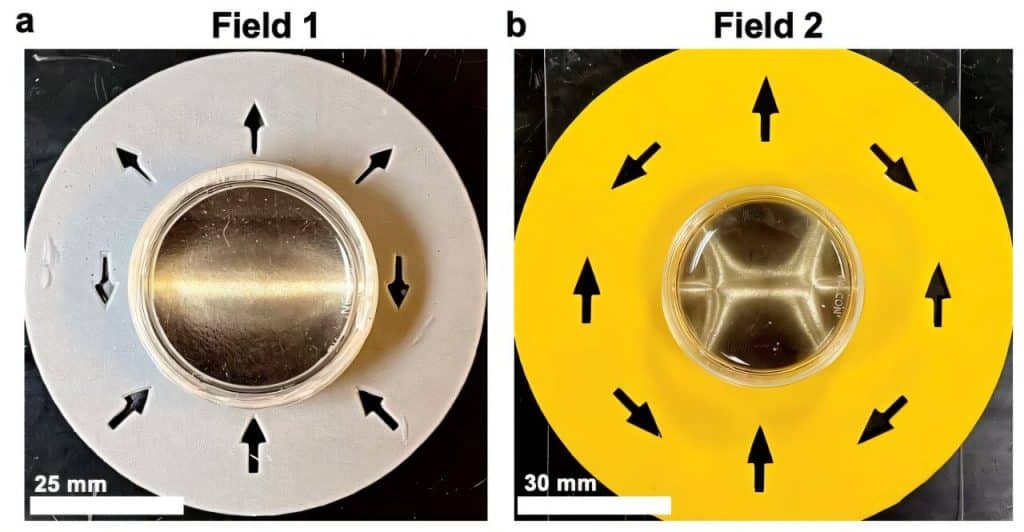

Using a type of 3D printing called digital light processing, they employed magnetic fields to align the molecules during printing. This technique allowed them to produce complex LCE shapes that react predictably to heat.

“Aligning the molecules is essential for harnessing LCEs’ full potential in advanced applications,” says Roach.

A Second Innovation: Energy Dissipation

In related research published in Advanced Engineering Materials, Roach and his team explored the energy-damping properties of LCEs. Using a fabrication method called direct ink writing; they created damping devices capable of dissipating mechanical energy across various vibrations. These devices could revolutionize systems like:

- Automotive shock absorbers.

- Seismic dampers for earthquake-resistant buildings.

- Vibration dampers on bridges.

This work was a collaboration between OSU students and researchers from Sandia, Lawrence Livermore, and Navajo Technical University.

Looking Ahead

This breakthrough in 3D printing and molecular alignment opens the door to advanced materials that respond to stimuli in groundbreaking ways. “Our work paves the way for innovations across multiple fields,” says Roach.

The potential of liquid crystalline elastomers is vast, from robotics and biomedical implants to energy systems and aerospace applications. Thanks to these advancements, the future of shape-changing materials looks brighter than ever.

Source:https:techxplore.com