How to Calculate the Uncertainty of a Measurement? [PSU example]

First, you must identify all sources of uncertainty in a measurement. Say you want to measure a PSU’s efficiency; you have to take the following into account besides the environmental conditions:

The equipment that you will use:

- AC Source

- DC Loads

- Power Analyzer

- Test Fixture

- Cabling

Then, you have to calculate the uncertainty of each of the above, which will actually affect the efficiency measurement. The individual uncertainty levels combined will provide the total uncertainty.

Uncertainty Evaluation Procedure

The main steps to evaluating the overall uncertainty of measurement are:

- Identify all sources of uncertainty: Determine the factors contributing to uncertainty, like instrument precision, environmental conditions, or measurement methods.

- Estimate individual uncertainties: Assign uncertainty value to each source, often based on instrument specifications or calibration.

- Determine the type of uncertainty: Classify each uncertainty as systematic (consistent) or random (variable).

- Calculate the combined uncertainty:

- For addition or subtraction, Add the absolute uncertainties.

- For multiplication or division, Add the relative (percentage) uncertainties.

- Use error propagation formulas: Apply the correct formulas when combining uncertainties for complex calculations, especially for functions of multiple measurements.

- Account for correlated uncertainties: If any measurements are related, adjust for the correlation when combining uncertainties.

- Express the overall uncertainty: Determine the total uncertainty, often as a range (e.g., 10.0 ± 0.2).

- Report the result: Present the measurement with its associated uncertainty, indicating the precision of the result.

Standard Uncertainty Definition

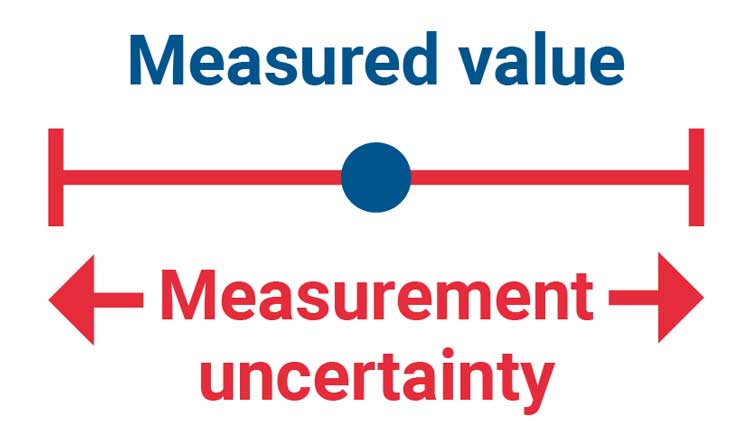

Standard uncertainty is the estimated uncertainty of a measurement expressed as a standard deviation. It represents the range within which the true value of a measurement is likely to lie, with a certain level of confidence (typically 68% for a normal distribution). The symbol for standard uncertainty is usually represented by u(x), where x is the measured quantity. It indicates the uncertainty associated with that particular measurement.

Standard Uncertainty Calculation Example – Type A

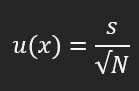

Say we have a number of repeated readings from a sample (e.g., a PSU’s efficiency at 100% load, conducted on different days by different operators). We calculate the mean value () and the standard deviation (s). From these, we can get the estimated standard uncertainty u of the mean (x) with the following formula:

Eq1: Where N is the number of measurements

Standard Uncertainty Calculation Example – Type B

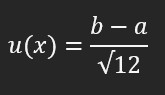

If we don’t have enough information, we can still get an estimate of the upper and lower limits of the uncertainty. We will have to assume the distribution of the values. For example, the standard uncertainty for a uniform distribution is:

Eq2: Where a and b are the limits of the rectangular distribution (the minimum and maximum values).

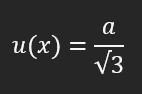

We can also use the following type:

Eq3: Where a is the semi-range (or half-width) between the upper and lower limits.

Uniform distribution patterns are the most common, but you should keep in mind that uncertainties imported from calibration certificates are typically normally distributed (spread factor k=2).

Can Type A and Type B Uncertainty Levels be Combined?

Yes, they can, and in some cases, you actually have to combine them to get the combined standard uncertainty.

Combined standard uncertainty refers to the overall uncertainty in a measurement that arises from multiple independent sources. It is the result of combining individual uncertainties from different sources, such as instrumental errors, calibration errors, or measurement techniques.

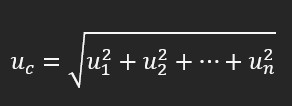

Eq4: Where u1, u2,…,un are the standard uncertainties from each source.

This is the simplest scenario and applies when the uncertainty levels are independent of each other. If the uncertainty levels are correlated, a more complex approach is needed, which is beyond the scope of this article.

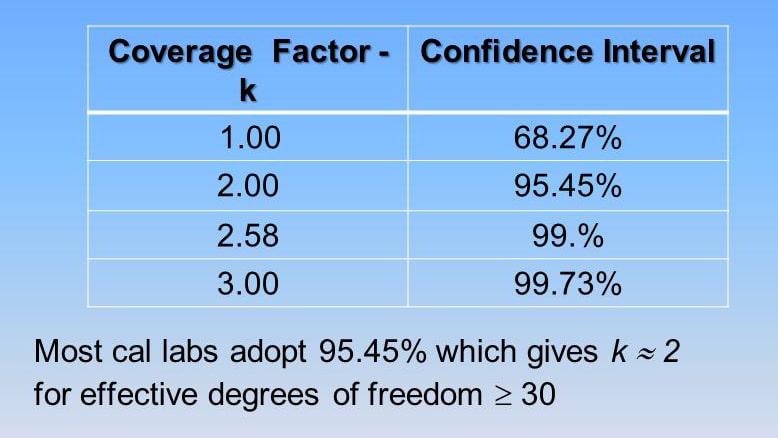

Coverage factor (k)

The coverage factor (k) is a multiplier used to calculate an interval around a measurement result within which the true value is expected to lie with a certain confidence level. It is typically used in conjunction with the standard uncertainty to define a confidence interval.

For example:

- k = 1 corresponds to a 68% confidence level of a normal distribution.

- k = 2 corresponds to a 95% confidence level (most commonly used).

- k = 3 corresponds to a 99% confidence level.

The result is often expressed as:

- Measurement ± k × uc

Where uc is the standard uncertainty.

Have you participated in any inter-laboratory comparison (ILC) or proficiency testing to validate the accuracy of your methods? If not, do you have plans to?

We just finished EMI PT testing, and I am waiting for noise testing PT to begin.

We cannot find any PTs for efficiency and fan performance, so we will coordinate something with a manufacturer. The ISO provides this capability if you cannot find a PT category. We frequently also compare our results with those of the factory and other labs, but as you know, the 17025 asks for PTs and not just any lab.

Now your laboratory is accredited, and you have an ISO/IEC 17025 certificate? You might be the first hardware reviewer who is legitimate.

Our lab works under ISO 17025 for quite some time now. We have our system implemented several years ago, based on our knowledge and through some external consultants we hired.

We will have the first inspection in the following months, and we also applied for ISO 17065 which will allow Cybenetics to enter Energy Star. We would obtain 17025 years ago, but we moved the lab 2x times in the last two years. Now that we bought the damn building, we go full speed to it!

To get ISO 17025, you must operate for at least six months under this ISO’s guidelines. We operate for many years under that since this is the way.

This kind of ISO I am afraid is NOT for reviewers because it is too complex, too expensive and requires a crazy tight system. If there wasn’t Cybenetics I would never be able to even think of it. Basically Cybenetics gets it. HWbusters just uses Cybenetics data 🙂

Into this year we will get the cert, we DONT have it yet. We filled the application in December 2024 and we are waiting for the first pre-inspection in the next month (hopefully). My goal is to have both ISOs within 2025 (17025 and 17065)

Wow! Impressive