Where do all the problems in measurements derive?

Understanding the main factors that can alter the results and divert us from the true readings is essential.

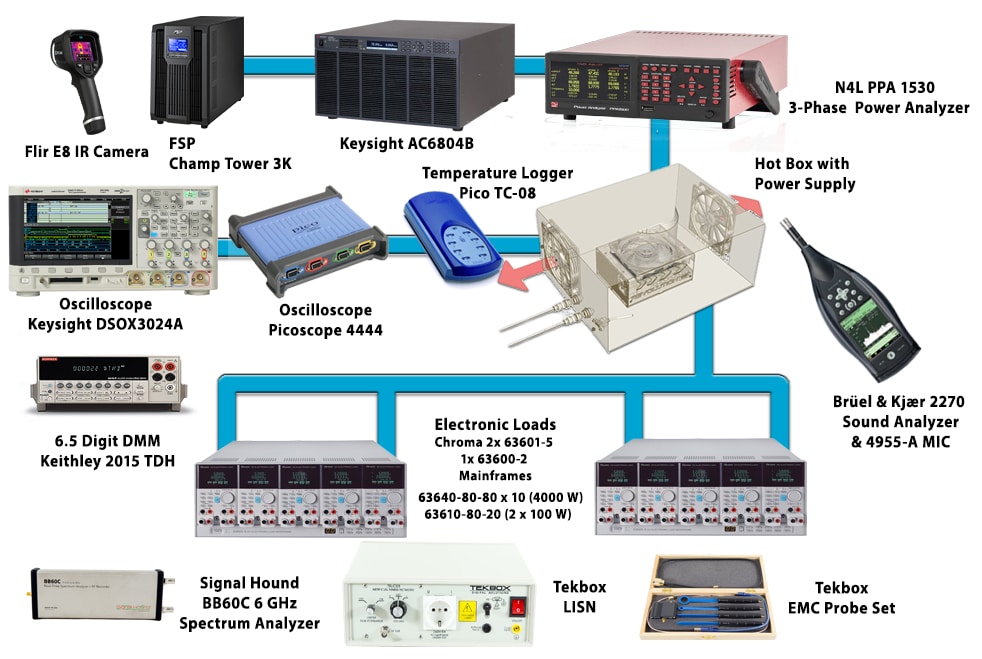

Instruments: If they are not calibrated and properly maintained, they will not deliver accurate results. Moreover, if your instrument is calibrated, the corresponding report will have an uncertainty level, which you must consider.

Operators: If the operator doesn’t know how to handle the instrument and measures incorrectly (e.g., voltage probes are not installed correctly in a PSU’s cables), the results will be highly deviant from the actual readings.

Device Under Test: If you have a PSU with highly unstable load regulation or operation in general, it will be challenging to get accurate readings.

Sample pool: You cannot know if the sample you tested performs similarly to samples from previous or future production batches. The ideal scenario would be to test all samples going out of a production line, which is done to some degree, at least in PSUs, in some highly automated production lines. Still, days of testing are required for thorough results, which is impossible.

Environmental conditions play a massive role in every measurement you take. You should keep them as stable as possible. Environmental conditions should be as close as possible for all sample measurements to compare results.

What Should NOT Be Included in the Uncertainty Measurement

The operator mistakes should not be included because you cannot know when someone will make a mistake and how large this will be (aka how much it will affect the measurements). So, from the moment this is entirely random, you cannot include it in the uncertainty.

Have you participated in any inter-laboratory comparison (ILC) or proficiency testing to validate the accuracy of your methods? If not, do you have plans to?

We just finished EMI PT testing, and I am waiting for noise testing PT to begin.

We cannot find any PTs for efficiency and fan performance, so we will coordinate something with a manufacturer. The ISO provides this capability if you cannot find a PT category. We frequently also compare our results with those of the factory and other labs, but as you know, the 17025 asks for PTs and not just any lab.

Now your laboratory is accredited, and you have an ISO/IEC 17025 certificate? You might be the first hardware reviewer who is legitimate.

Our lab works under ISO 17025 for quite some time now. We have our system implemented several years ago, based on our knowledge and through some external consultants we hired.

We will have the first inspection in the following months, and we also applied for ISO 17065 which will allow Cybenetics to enter Energy Star. We would obtain 17025 years ago, but we moved the lab 2x times in the last two years. Now that we bought the damn building, we go full speed to it!

To get ISO 17025, you must operate for at least six months under this ISO’s guidelines. We operate for many years under that since this is the way.

This kind of ISO I am afraid is NOT for reviewers because it is too complex, too expensive and requires a crazy tight system. If there wasn’t Cybenetics I would never be able to even think of it. Basically Cybenetics gets it. HWbusters just uses Cybenetics data 🙂

Into this year we will get the cert, we DONT have it yet. We filled the application in December 2024 and we are waiting for the first pre-inspection in the next month (hopefully). My goal is to have both ISOs within 2025 (17025 and 17065)

Wow! Impressive