Box, Contents & Bundle

The box features a photo of the product and the model’s description. The rich bundle is contained in a smaller package.

The fan’s bundle is rich, including the following:

- NA-RC16 Low-Noise Adaptor (L.N.A.)

- NA-YC1 4-pin PWM splitter cable

- NA-EC1 30cm extension cable

- 4x NA-AV2 anti-vibration mounts

- NA-AVG2-LR anti-vibration gasket

- 4x NA-AVP1-LR load-relief anti-vibration pads

- Fan screws

The fan, which has nine blades, is made by Sterrox LCP. In this section, I want to stay on some of the fan’s most important features:

Progressive-Bend impeller

The NF-A14x25 G2 features a Progressive Bend Impeller with flow acceleration channels and winglets. Its nine blades are swept backward close to the hub and progressively bent forward further out. Working in tandem with the Centrifugal Turbulator hub, this design not only helps to push more air toward the outer blade areas where efficiency is higher but also ensures maximum lift and near-uniform loading across the entire blade span.

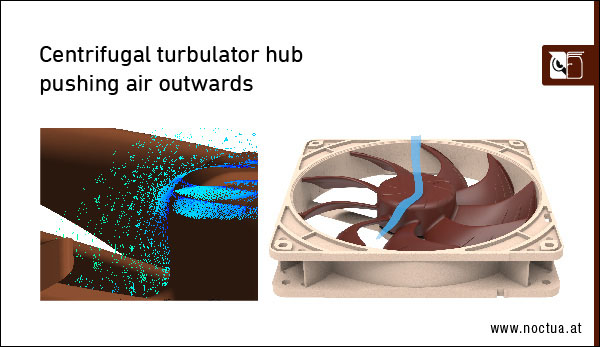

Centrifugal Turbulator Hub

The new Centrifugal Turbulator hub design improves flow attachment in the hub region. At the same time, its centrifugal driving motion pushes air outwards from the hub area where efficiency is low due to the slow rotational speed towards the outer, high-efficiency zones of the blades, thereby increasing overall efficiency by optimizing fluid distribution across the impeller area.

Flow Acceleration Channels

The NF-A14x25 G2 impeller features suction-side Flow Acceleration Channels. By speeding up the airflow at the crucial outer blade regions, this measure reduces suction side flow separation, leading to better efficiency and lower vortex noise.

Winglets

Winglets can help reduce tip vortices caused by the pressure differential between the suction and the pressure side of fan blades but bear the risk of reducing efficiency due to extra fluid displacement in high-velocity regions. The NF-A14x25 G2’s small winglets have been fine-tuned to provide consistent efficiency gains working in tandem with its Progressive-Bend blade geometry, Flow Acceleration Channels, and AAO frame.

Ultra-tight tip clearance

The NF-A14x25 G2 has a tight tip clearance (distance between the blade tips and the inside of the frame) of only 0.7mm. This design helps the NF-A14x25 G2 work more efficiently against back pressure, such as on heatsinks or radiators, by reducing leak flows through the gap between the impeller and frame.

Stepped Inlet Design

Noctua’s Stepped Inlet design adds turbulence to the influx to facilitate the transition from laminar to turbulent flow. This reduces tonal intake noise, improves flow attachment, and increases suction capacity, especially in space-restricted environments.

Inner Surface Microstructures

With the tips of the fan blades plowing through the boundary layer created by the Inner Surface Microstructures, flow separation from the suction side of the blades is significantly suppressed, which results in reduced blade passing noise and improved airflow and pressure efficiency.

Some more close-up photos of the fan.

Kinda surprised you didn’t include the NH-D15. The NF-A14x25 is the successor to the D15. Wouldn’t you want to know how much better it is to the D15? Totally lame review.

Do you understand what you write? You confuse a cooler (D15) with a fan?

As an example: https://postimg.cc/67WQtBP7 (link to https://postimages.org)

It may hurts eyes, sorry 🙂

Brighter colors – NF-A14x25 G2, 50% PWM

Dimmer – Silent Wings 4 Pro 140, Mid Range, 50% PWM

It looks like the NF-A14x25 G2 is superior to the SW4 Pro as a fan for the case (I’m guided by the graph from Noctua: https://noctua.at/pub/media/wysiwyg/A14_further_reading_1_Highly_optimised_PQ_curve_for_all_applications.png) and for the radiator of the tower cooler, but loses as a fan for the radiator, which generally corresponds to tests on other resources.

Greetings!

Thank you so much for your reviews, everything is simple, technologically advanced and accurate.

I would like to suggest adding a P/Q Graph for 20, 25 and 30 db to compare fans in the “Normalized Noise Tests” category.

It would probably be more visual, and correct, from the point of view of testing performance close to real.

Have you considered this option?

As an example: https://ibb.co/4SSw81X

It hurts my eyes, I’m sorry 🙂

Brighter colors – NF-A14x25 G2, 50% PWM

Dimmer – Silent Wings 4 Pro 140, Mid Range, 50% PWM

It looks like the NF-A14x25 G2 is superior to the SW4 Pro as a fan for the case (I’m guided by the graph from Noctua: https://noctua.at/pub/media/wysiwyg/A14_further_reading_1_Highly_optimised_PQ_curve_for_all_applications.png ) and for the radiator of the tower cooler, but loses as a fan for the radiator, which generally corresponds to tests on other resources.