Test Methodology

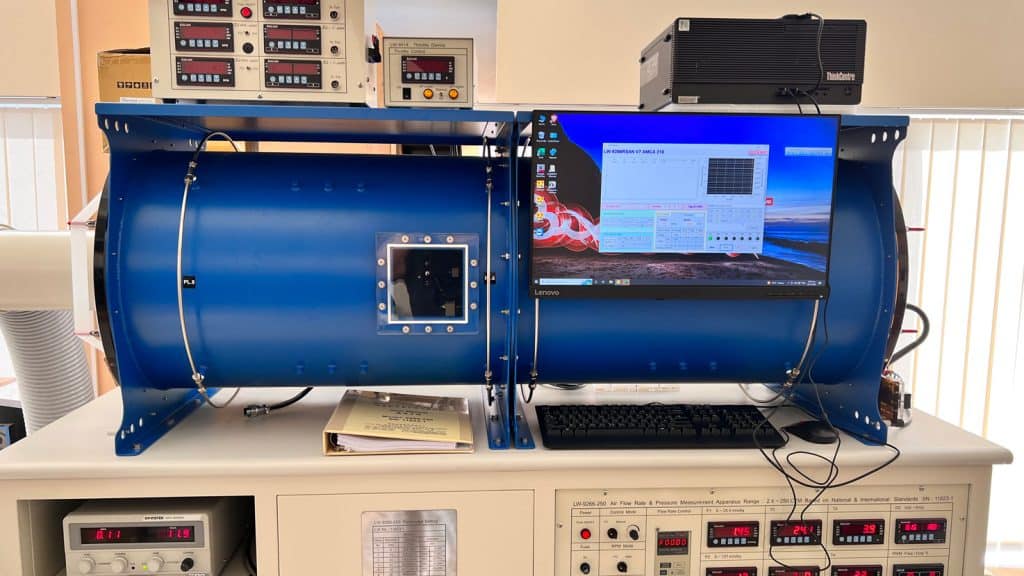

I use an LW-9266 Fan PQ performance measurement apparatus to evaluate cooling fans. This highly sophisticated scientific instrument was made in Taiwan by Long Win.

Fan Testing Machine Technical Specifications:

- Manufacturer: Long Win Science & Technology Corporation

- Air Flow Rate: 2.4 – 250 CFM

- Accuracy of Air Flow Rage: <3.5% INFS

- Repeatability error: < 2%

- Static pressure: 0-20mmAq (100mmAq with the high static pressure throttle device)

- Overall Dimensions: 0.7 (W) x 2.2 (L) x 1.6 (H) m

- Power Source: 220VAC, 5A, Single Phase, 50/60Hz

- Based on Standards: ISO 5801-2007, AMCA 210-0, ASHRAE 51-2007, IEC 61591-2005, GB/T 1236-200

Besides the Long Win machine, I also use the following equipment.

Testing Equipment:

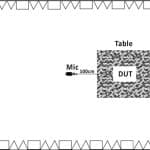

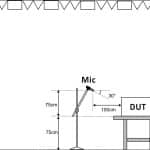

- Noise Test Environment: Hemi-Anechoic Chamber with 6 dB(A) noise floor

- Conditions: 25 (+-2) degrees Celsius, 40-50% humidity

- Sound Analyzer: Bruel & Kjaer 2270-S G4

- Microphone: Bruel & Kjaer Type 4955-A

- Mic Calibrator: Bruel & Kjaer Type 4231

- Data Logger: Picoscope TC-08

Pages:

How would these compare to the P14 pros?

Have to check the P14 Pros to find out 🙂

Haha, fair. I will keep an eye out if you manage to test them. Cheers!

Strange that you mention that this one has a rifle bearing – I checked on their site and every fan has the same picture of the bearing. Seems either wrong picture or wrong specs?

correction: it is indeed a FDB & not a Rifle bearing. according to arctic & comparison with other rifle bearings (unless those bearings weren’t rifle bearings)

I wonder which is actually correct. They mention FDB in their spec sheet pdf file, not just on their site.

One would think that seeing as they actually have it written down in their actual sheets.

Furthermore I found this article that states the P14 Max is using FDB bearings – https://www.hwcooling.net/en/new-arctic-p14-max-anti-vibration-and-high-speed/

The early manufactured P12 MAX fans use dual ball bearings. The packaging of Arctic fans is very crude so that many ball bearings were damaged during shipping and make loud noise when using, leading to a lot of returns and complaints. So the factory decided to use FDB bearings, which is cheap, short lifetime but won’t make obvious noise if thrown down. Only few users know how to replace the bearings of a dual ball bearing fan. Users also lack sources of original ball bearings suitable for silent motors. So when the P14 MAX fans come out, they are all using FDB. I understand the manufacturer’s decision to use FDB bearings. But I will only consider buying P14 CO.

How do thes stack up against Noctua?

The best 140 fan now should be the 9RA1412P1G001 from Sanyo Denki (it is 38mm thickness, 25mm is too thin for a 14cm fan). You can get one from Digikey, Mouser or Chip1stop and some other Electronics sales websites(the price in Chip1stop is much more reasonable). The price is high but worth. Hope to see the review of 9RA1412, it is really a good fan for PC building. I think the coming new 14025 fan from Noctua is hard to compete with this product. You should be careful about the transportation when ordering, the ball bearings of this fan are easy to be damaged when shipping and become noisy. It might be a good idea to prepare new 623ZZ(R1030ZZ)ball bearings for silent motors to replace the damaged ones in advance.

Sanyo Denki is a top fan manufacturer.

maybe…but… Rated current [A] = 1.1 > 1.0

…is there some additional SATA connector except for PWM?

…and normalized for noise levels, I don’t think it will be as good as the new NF-A14…despite its advantageous thickness.

1.1A is safe for most motherboard as long as you only connect one fan to one socket. I don’t recommand the DC version since these versions may have additional motor drive noise. It is of course more reliable to supply power through an additional fan controller.

Some users commented that the noise experience of 9RA1412 at 1200 rpm is close to that of the A12X25 at 1000 rpm.

However,9RA1412 is designed for industrial application, which has strict standards and regulations for fan installation. For example, the fan inlet surface should be unobstructed, otherwise it will lead to an additional loud noise. For most cases nowadays with fan mounting bracket for both 12 and 14cm fans,the air inlet surface of the air inlet fan will be close to the bracket and result in additional noise. The problem is not significant for most consuming fans,but for 9RA the problem can not be ignored. When you decede to use 9RA fans for the best thermal and noise performance, you should choose your case carefully, or even design and build one by yourself(lol).