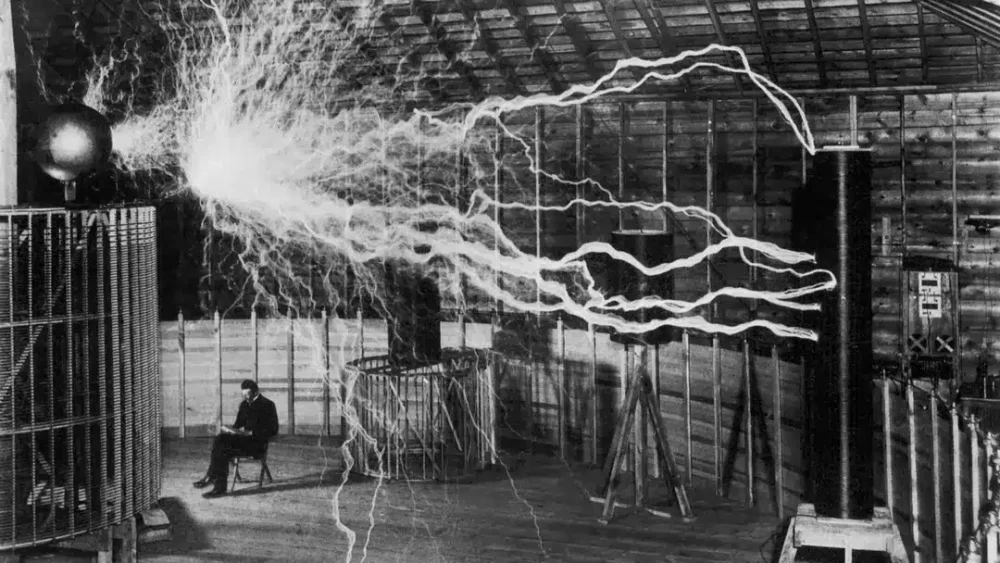

A research team has revived a century-old Nikola Tesla design and used it to build a system that generates electricity from compressed air, without any moving parts touching. The device harvests static electricity produced naturally in industrial air systems and turns what was once a safety hazard into a source of usable power.

Bladeless Turbine Meets Triboelectric Tech

The system combines two key elements:

- A bladeless Tesla turbine, patented by Nikola Tesla in 1913. Instead of blades, it uses smooth, closely spaced discs that spin thanks to viscous drag as compressed air spirals inward. At 0.2 MPa pressure, the rotor can reach 8,472 RPM with airflow speeds up to 300 m/s.

- Triboelectric layers, materials that generate static electricity when rubbed together. As compressed air, which often carries dust and moisture particles, flows through the turbine, collisions create electrostatic charges. The system captures this charge directly.

The result is a contactless generator that produced 800 volts and 2.5 amps in testing, operating at 325 Hz, entirely from compressed air already present in industrial settings.

Why This Matters for Industry

Compressed air is widely used in manufacturing, robotics, and automotive plants, but it has a hidden problem: static buildup. This not only wastes energy but can also pose explosion risks or interfere with sensitive electronics.

This new system offers a dual-purpose solution:

- Generates electricity from otherwise wasted electrostatic energy.

- Neutralizes hazardous static charges in the air, improving safety.

- Can be integrated into existing compressed air systems without major retrofits.

As a bonus, the high-voltage output helps remove dust and moisture from the air by generating negative ions, acting like an integrated air cleaner.

Old Idea, New Twist

Nikola Tesla’s turbine was long considered an elegant but underutilized concept. By pairing it with modern triboelectric materials and solid-state electronics, researchers have given it a practical, high-value application: turning airflow friction into clean power.

Bottom Line

This isn’t just another energy-harvesting experiment, it’s a smart reuse of existing infrastructure. Factories already using compressed air could potentially lower energy costs, improve air quality, and reduce static-related risks, all with one add-on device.

While still in the research phase, the system highlights how historical ingenuity (Tesla’s turbine) and modern materials science can team up to solve two problems at once: capturing waste energy and making industrial workplaces safer.

If scalable, this “contactless electricity” approach could give sustainable engineering a surprising spark, straight from the air we already pump