Short answer: Yes — you absolutely should care, even though EN 55032 does not formally limit emissions below 150 kHz.

What EN 55032 officially says [this standard defines how noisy a product is allowed to be on the mains and in the air]

- Conducted EMI limits apply from 150 kHz to 30 MHz

- Below 150 kHz is outside the regulated band (in EN 55032 / CISPR 32)

So on paper:

“Below 150 kHz doesn’t matter.”

Why that statement is dangerously incomplete

Below-150 kHz noise moves upward

- Low-frequency noise does not stay put.

- Mechanisms that push it into the regulated band:

- Non-linear LISN impedance

- APFC control loop interaction

- Rectifier / totem-pole commutation

- Burst-mode standby operation

- Magnetic core hysteresis

👉 What starts at 20–80 kHz often shows up as 150–300 kHz peaks in the final scan.

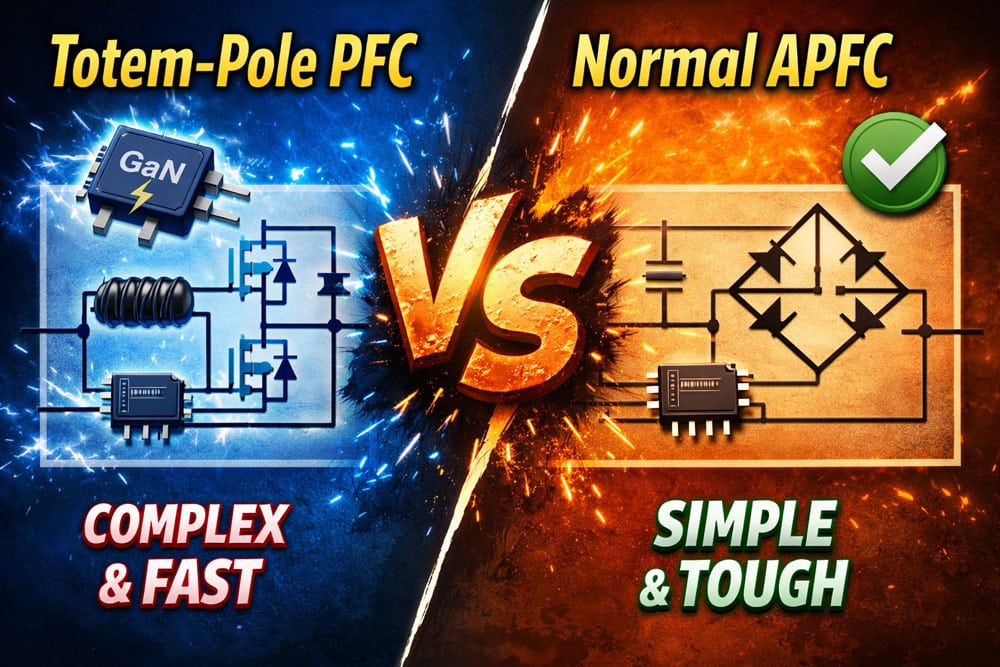

Totem-pole PFC makes it worse

In bridgeless / totem-pole designs:

- There is no diode bridge isolation

- Noise couples symmetrically into L and N

- CM paths are much stronger

Result:

- Sub-150 kHz energy couples directly into the LISN**

- Filters sized only for >150 kHz saturate or detune

** A LISN (Line Impedance Stabilization Network) is a standardized network placed between the mains and the device under test during conducted EMI measurements.

This is why many totem-pole platforms fail just above 150 kHz, even when the issue originates below it.

Standby rails are the #1 hidden source

Most problematic sources:

- Burst mode

- Pulse skipping

- Digital or quasi-digital controllers

- Very low switching frequencies (10–40 kHz)

Even if:

- The PSU passes at full load

- The main PFC looks clean

👉 5VSB noise below 150 kHz often defines the final EMI margin.

Labs do look there (even if the standard doesn’t)

In real EMC labs:

- Engineers always pre-scan below 150 kHz

- Failures at 150–180 kHz almost always trace back lower

- Debugging starts at 9 kHz or 30 kHz, not 150 kHz

So while it’s “out of spec,” it’s not out of relevance.

Practical rule of thumb (used by PSU designers)

If you see strong energy below 150 kHz, assume you have a future EN 55032 problem. Also think about the users who will buy these products, and make them better!

Especially if:

- Totem-pole PFC is used

- Digital control or burst mode exists

- You rely on minimal EMI filtering for cost reasons

Final answer

EN 55032 doesn’t regulate below 150 kHz — but your PSU absolutely should.

Ignoring it is one of the fastest ways to:

- Lose EMI margin

- Fail late in certification

- Get inconsistent lab results

- Increase RMA rates and have users lose faith in you and your brand

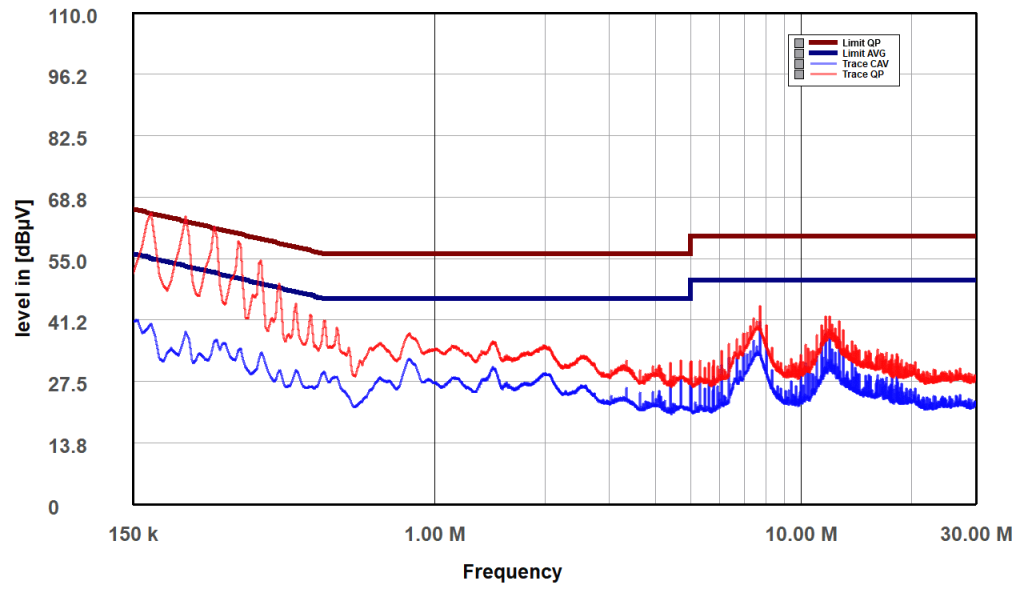

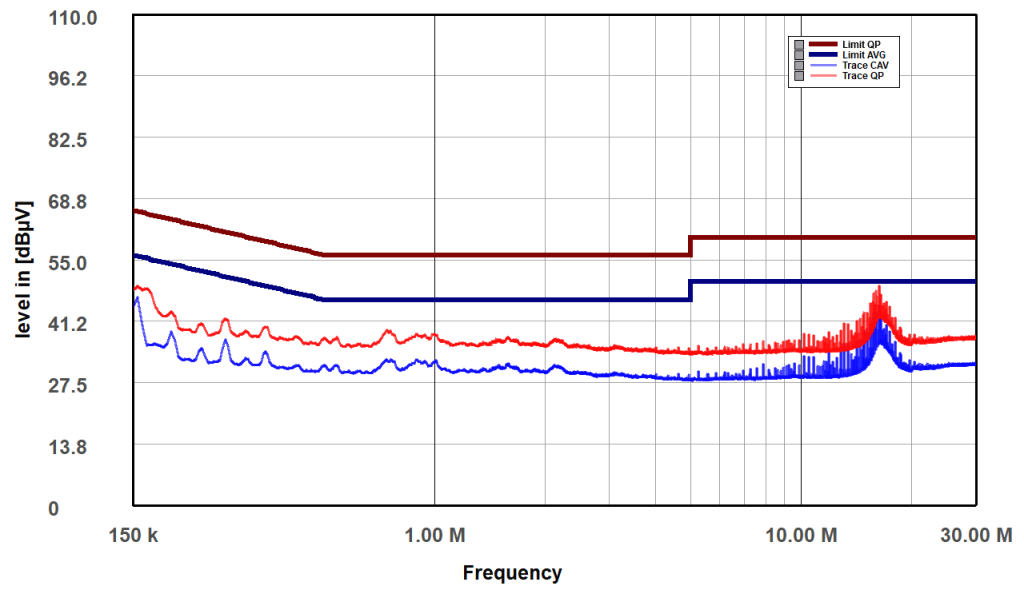

An Example of What You Can Expect in Real Life

In this example, the increased noise below 150 kHz overloads the EMI receiver. It resonates above 150 kHz. Only if we add 10 dB of extra attenuation does the EMI receiver not overload; in essence, we “lose” information about the noisy sub-150 kHz range, and the signal also loses much of its initial information, since we make the receiver “deaf” with the extra attenuation.

EMI noise below 150 kHz can cause audible noise, oscillation, or erratic PF at light load. Audible noise is translated to coil whine, while erratic PF readings lead to lost energy. There are several cases in our lab where the PF readings under light load were all over the place, and the same was true for the power analyzer’s AC Watt readings, which were heavily affected by increased EMI conducted noise. In such cases, we ask the manufacturer to re-check and improve the design.

How does it affect the PC system, more specifically, the mainboard?

- Low-frequency CM noise passes through PSU → cables → motherboard.

- Pollutes 12V → VRM inputs. Every significant component in your system has its own VRMs.

- Leads to higher VRM ripple at light load.

Symptoms

- Random freezes at idle

- USB dropouts

- NVMe or SATA glitches

- Coil whine synced with PSU behavior

That’s why serious desktop PSU designs control sub-150 kHz noise first, even though the standard doesn’t explicitly demand it.