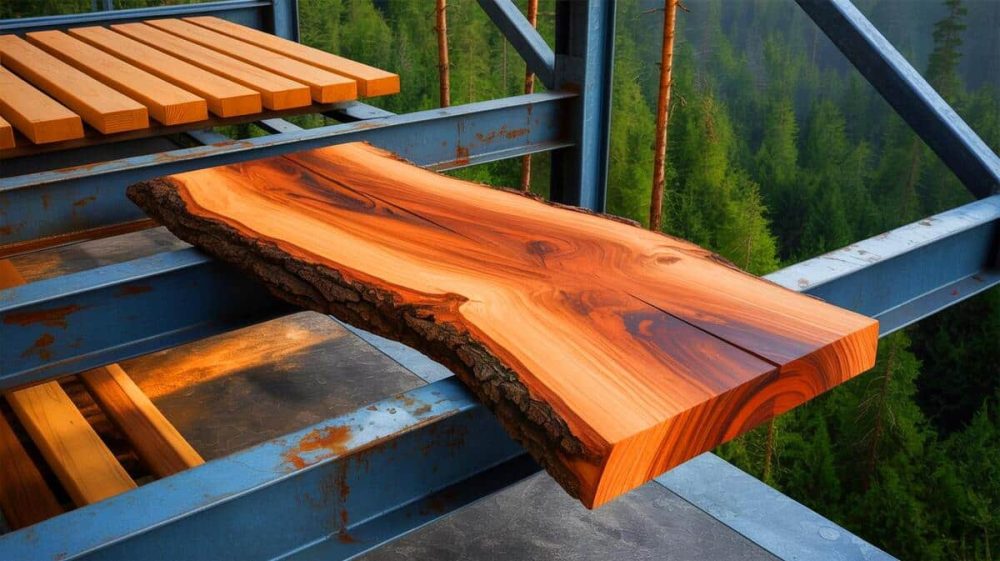

Imagine a future where gleaming skyscrapers aren’t built with cold steel and heavy concrete—but with wood. Not just any wood, but a next-gen material that’s tougher, lighter, and greener than the metals we rely on today. Enter Superwood, a game-changing innovation from Maryland-based startup InventWood, that may be about to shake the very foundations of the construction industry.

What Is Superwood?

Superwood is no ordinary lumber. Developed by researchers at the University of Maryland and commercialized by InventWood, it’s a high-performance biogenic material that is:

-

12× stronger than natural wood

-

10× more durable

-

Stronger than steel

-

Lighter than aluminum

-

Fire-, rot-, and pest-resistant

Through a molecular-level transformation, scientists remove lignin (the stiff component in wood), then compress what’s left under extreme heat and pressure. The result? A dense, tough-as-nails material that keeps the aesthetic charm of wood—with the mechanical muscle of metal.

“We’re simply unlocking wood’s hidden potential,” says InventWood CEO Alex Lau. Backed by over $50 million in funding—including the U.S. Department of Energy and Department of Defense—Superwood is poised for mass production in 2025.

Building Tomorrow: Superwood vs. Traditional Materials

| Feature | Superwood | Steel | Aluminum |

|---|---|---|---|

| Strength-to-weight | 10× better than steel | High strength, but heavy | Light, but weaker than steel |

| Fire resistance | Class A (doesn’t sag or burn) | Can lose integrity in heat | Melts quickly under fire |

| Sustainability | Carbon-locking, renewable | Carbon-intensive to produce | Energy-heavy manufacturing |

| Aesthetic | Warm, natural wood look | Industrial, cold | Sleek, metallic |

Superwood isn’t just about being strong. It’s about redefining what sustainable construction looks like. InventWood sources wood locally, reducing transportation emissions and avoiding carbon-heavy processes like smelting. In fact, it’s estimated to cut embodied carbon by up to 70% compared to traditional steel-heavy buildings.

The Science Behind It

The magic happens at the cellular level:

-

Lignin Removal – Lignin is stripped out, making the wood more flexible for densification.

-

Compression & Heat – The remaining cellulose is pressed and heated, forming a tight, interlocked matrix.

-

Sealant Finish – A bio-based treatment seals the panels, allowing vapor to pass but blocking liquid water.

This approach fuses biology and materials science, preserving the beauty of wood while endowing it with superhero-like properties.

From Skyscrapers to Headphones

Superwood’s versatility opens doors in many industries:

-

Construction – Structural beams, roofing, decking, facades.

-

Transportation – Potential use in cars, planes, and public transit.

-

Consumer goods – Furniture, audio gear, or even wearable tech.

-

Military & Aerospace – Durable, lightweight solutions for rugged use.

“This is about performance and purpose. Every plank we ship reflects our commitment to better, cleaner building,” says Lau.

A Greener, Stronger Tomorrow?

With commercial shipments expected in Q3 2025, Superwood’s timing is perfect. The global construction sector is facing intense pressure to decarbonize, and Superwood offers a powerful solution—without sacrificing strength, safety, or style.

Challenges remain, from scaling production to navigating building codes. But with government backing and growing demand for renewable materials, InventWood could be the Tesla of timber.