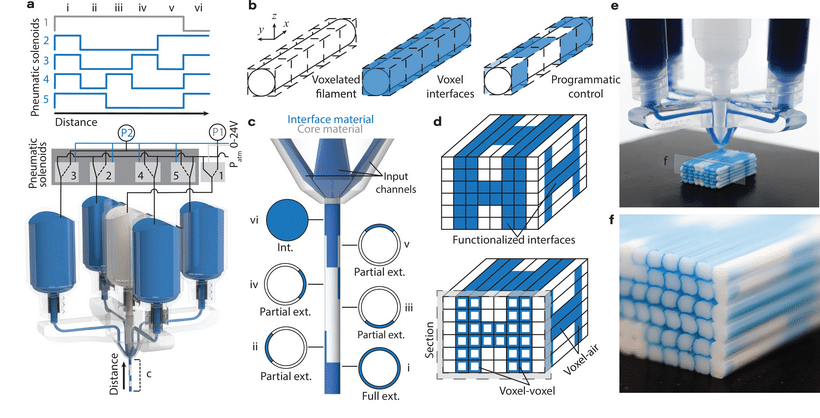

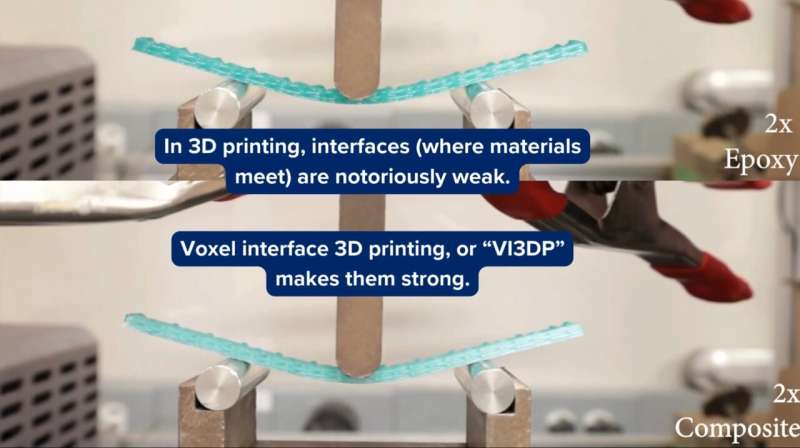

VI3DP, a groundbreaking innovation in 3D printing, is redefining the possibilities of printed objects by directly integrating optical, mechanical, and electrical properties into the interfaces—all within a single print. This advancement is achieved without increasing production time, material weight, or overall costs.

Doctoral candidate Daniel Ames highlighted the potential of this method:

“Adding properties like mechanical strength, optical clarity, or electrical conductivity is already feasible with 3D printing processes, such as material extrusion or jetting. However, these processes typically apply these properties in entire voxel-sized segments, compromising resolution and throughput. VI3DP allows us to embed these features within thin interfaces surrounding the voxels, massively expanding the potential applications for soft materials.”

The VI3DP technique embeds interfaces with unique physical properties, offering precision and functionality that has never been achievable in 3D printing.

“Interfaces are key because of the functionalities they enable,” explained Mueller, the study’s lead author. “With VI3DP, we can create thinner, more efficient interfaces, explore new material combinations, and integrate complex features like 3D circuits, electromechanical systems, data-embedded composite structures, and print-in-place mechanisms with unmatched precision.”

The team has already showcased this potential in their research and plans to explore these capabilities further in future studies.

“VI3DP establishes a robust platform for fabricating previously unimaginable structures,” added Ames.

The research team includes collaborators from Johns Hopkins University, doctoral candidate Sarah Propst, and visiting high school scholar Aadarsh Shah.

Source:techxplore.com